Anticorrosive paint composition comprising modified ceramic waste and preparation method thereof

A technology of ceramic waste and anti-corrosion coatings, applied in anti-corrosion coatings, chemical instruments and methods, polyurea/polyurethane coatings, etc., can solve the problems of land occupation and impact on the ecological environment, and achieve the effects of improving service life and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

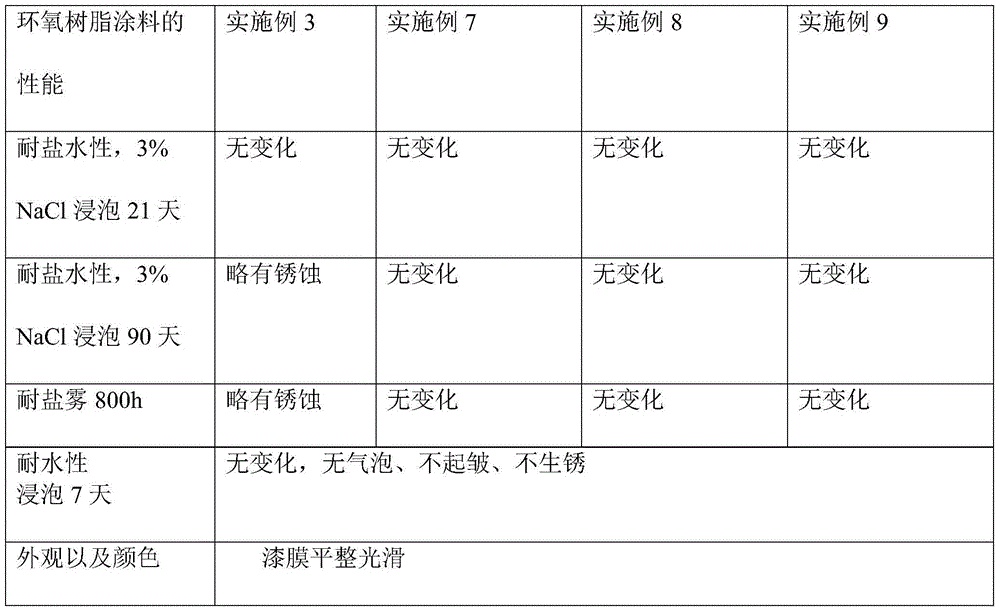

Examples

preparation example Construction

[0060] Preparation of Ceramic Waste Antirust Pigment (1)

[0061] Take 75 kg of 500 mesh (25 μm) ceramic waste powder prepared above, 15 kg of 500 mesh (25 μm) mica iron oxide powder, and 10 kg of 500 mesh (25 μm) phosphate rock powder, mix them evenly in a high-speed mixer, and add KH-550 (γ-chloropropyltriethoxysilane) 1kg was subjected to surface treatment to obtain ceramic waste antirust pigment (1), with an average particle size of 500 mesh (25 μm).

[0062] Preparation of Ceramic Waste Antirust Pigment (2)

[0063]Take 75 kg of 500 mesh (25 μm) ceramic waste powder prepared above, 20 kg of 500 mesh (25 μm) mica iron oxide powder, 5 kg of 500 mesh (25 μm) phosphate rock powder, and mix them evenly in a high-speed mixer, and add CT-114 (Monoalkoxy tris(-octylphosphorphenoxy) titanate) 1kg was subjected to surface treatment to obtain ceramic waste antirust pigment (2), with an average particle size of 500 mesh (25 μm).

[0064] Preparation of Ceramic Waste Antirust Pigmen...

Embodiment 1

[0068] Add 55 parts by weight of acrylic resin (ethyl acrylate / propyl acrylate / hydroxyethyl acrylate terpolymer, mass ratio about 60:33:7, number average molecular weight 51,000) and 15 parts by weight of xylene into the tank , stir and disperse evenly, then add dispersant polyacrylamide 0.7 weight part, low molecular weight polysiloxane defoamer 0.7 weight part, stir evenly, prepare corresponding varnish; Add ceramic waste antirust pigment (1) 25 in this varnish Parts by weight, porous carbon powder (BET specific surface area is 1000m 2 / g, the average particle diameter is 16 μm) 10 parts by weight, graphite powder 10 parts by weight, stirring and dispersing for a certain period of time, until each pigment and filler is fully wetted, a preliminary paint is obtained; this preliminary paint is ground, and the viscosity is adjusted with xylene , to a fineness of 60 μ m or less, the viscosity is about 16-20s (paint four cups), then add 3 parts by weight of 4,4'-diphenylmethane d...

Embodiment 2

[0072] Add 60 parts by weight of polyurethane resin (number average molecular weight 125,000) and 40 parts by weight of xylene into the adjusting tank, stir and disperse evenly, and then add 0.7 parts by weight of dispersant polyacrylamide and stir evenly to prepare the corresponding varnish; in this varnish Add ceramic waste antirust pigment (2) 40 weight parts, porous carbon powder (BET specific surface area is 1000m 2 / g, the average particle diameter is 16 μ m) 10 weight parts, graphite powder 15 weight parts, bentonite 10 weight parts, stir and disperse for a certain period of time, fully wetting to each pigment and filler, obtain preliminary paint; Molecular weight polysiloxane defoamer 0.7 parts by weight, and grind, adjust viscosity with xylene, until the fineness reaches below 60 μm, the viscosity is about 16-20s (coating four cups), then add 3.5 parts by weight of 4,4 '-diphenylmethane diisocyanate (MDI), stirring and mixing to obtain ceramic waste anticorrosion coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com