A kind of latent epoxy resin curing-foaming agent and preparation method thereof

A technology of epoxy resin curing and foaming agent, which is applied in the field of plastic additives, can solve the problems of difficult realization of foaming materials and single-component epoxy foaming systems, and achieves environmental protection of the synthesis process, increased carbon emissions, and utilization of raw materials. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

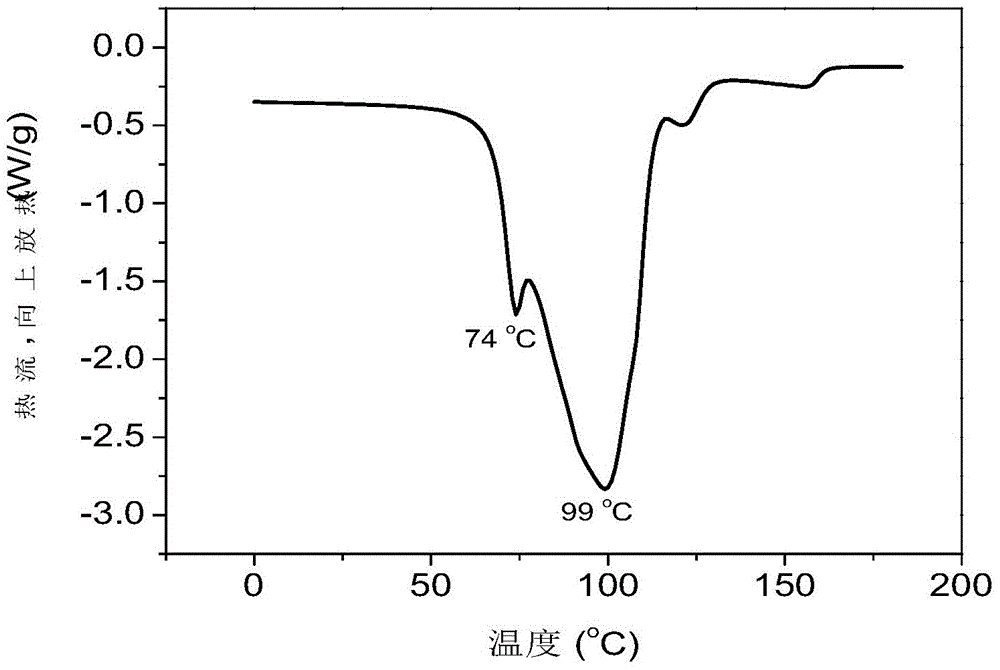

Embodiment 1

[0039] 5 g of mantanediamine (MDA) was added to the reaction vessel, and then 560 mL (495 g) of ethyl acetate was added, and stirred to form a solution with a uniform concentration of 1%. The industrial-grade carbon dioxide gas was introduced into the reactor below the liquid level at 200 mL / min, and the reaction was carried out under stirring for 12 hours. A white precipitate was obtained at the bottom of the reactor. The product was filtered and dried at room temperature in vacuo for 12 hours to obtain 5.2 g of a white powdery product, marked as B-MDA, with the structural formula:

[0040]

Embodiment 2

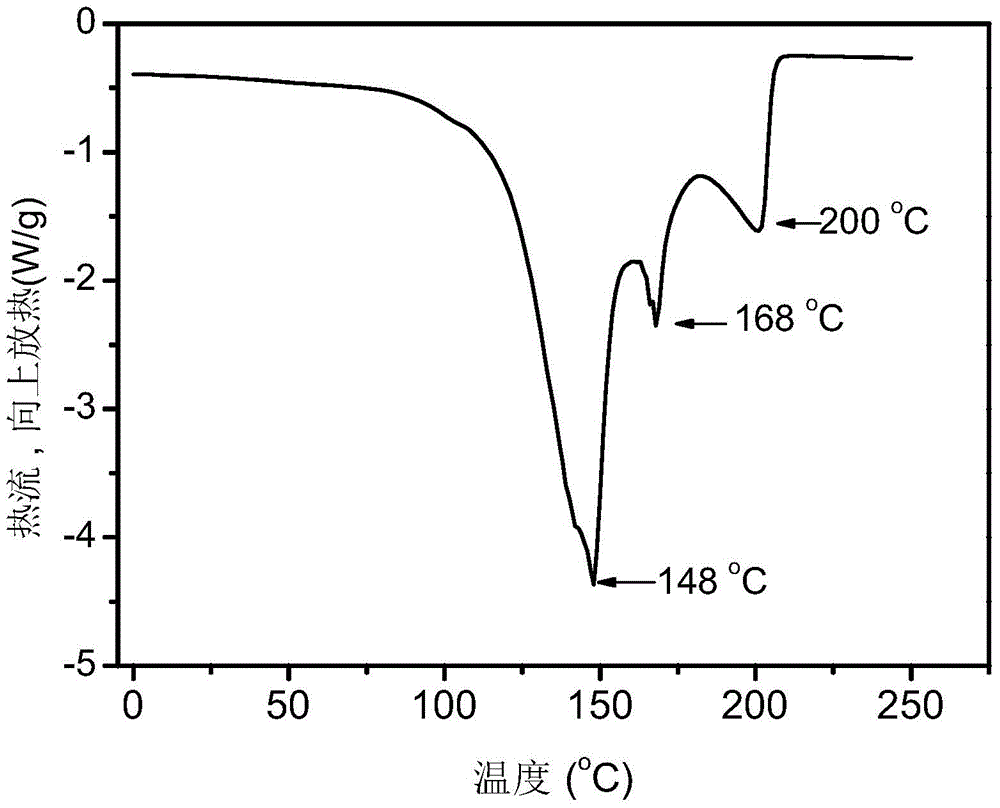

[0042] 50 g of diethylaminopropylamine (DEAPA) was added to the reaction vessel without adding any solvent, i.e. the concentration of the reactant was 100%. The technical grade carbon dioxide gas was introduced into the reactor below the liquid level at 40 mL / min, and the reaction was carried out for 30 minutes under stirring to obtain 54 g of white paste, which was marked as B-DEAPA, and the structural formula was:

[0043]

Embodiment 3

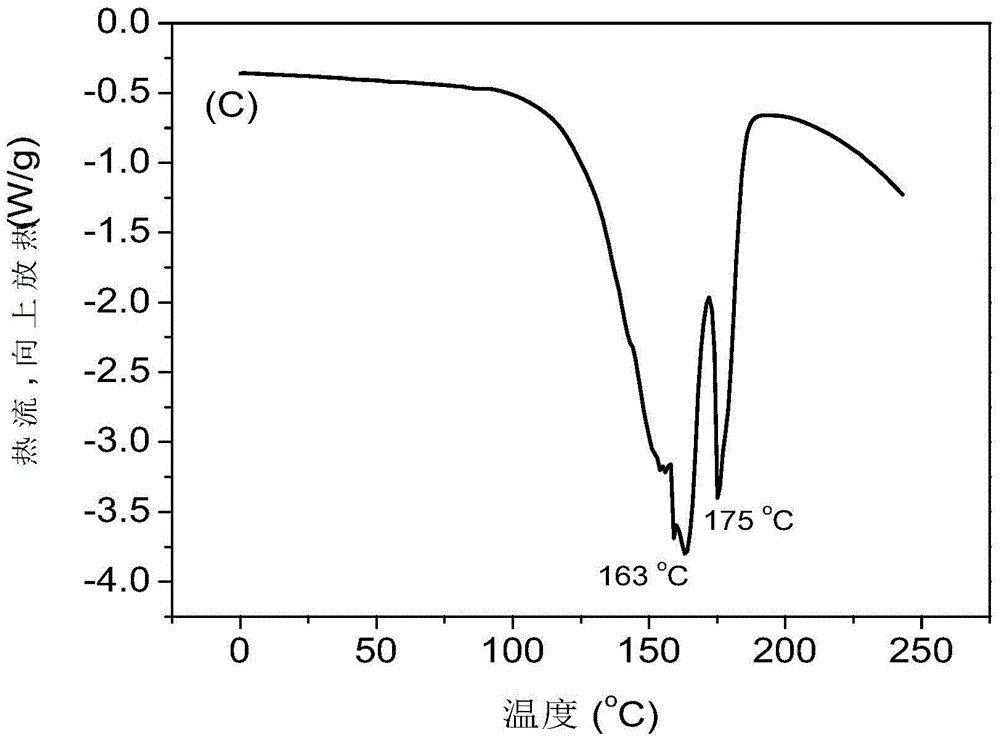

[0045] 50 g of N-aminoethylpiperazine (AEP) was added to the reaction vessel, and then 570 mL (450 g) of acetone was added, and stirred to form a solution with a concentration of 10%. The industrial-grade carbon dioxide gas was introduced into the reactor below the liquid level at 60 mL / min, and the reaction was carried out under stirring for 10 hours. A white precipitate was obtained at the bottom of the reactor. The product was filtered and dried at room temperature for 12 hours to obtain 65 g of a white powdery product, marked as B-AEP, with the structural formula:

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com