Device for treating high ammonia-nitrogen wastewater and method thereof

A high-ammonia-nitrogen, waste water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as unstable effluent quality, complex process flow, and long effluent sedimentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1, the device for processing high ammonia nitrogen wastewater

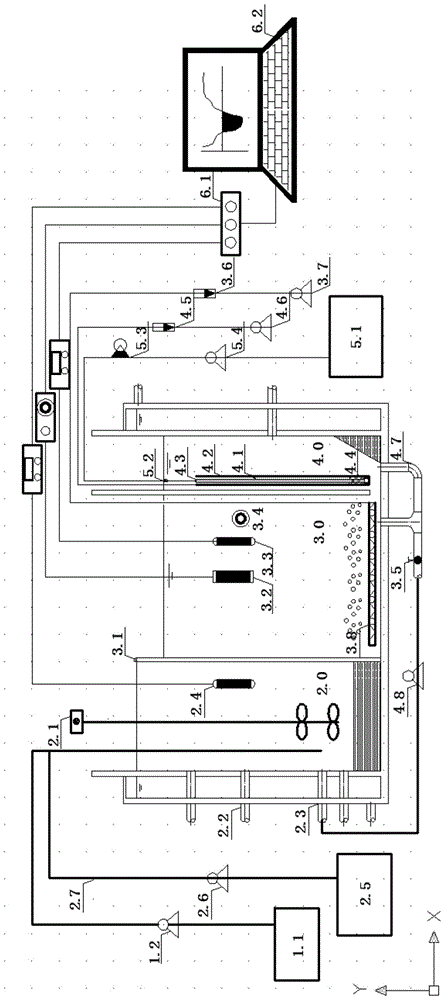

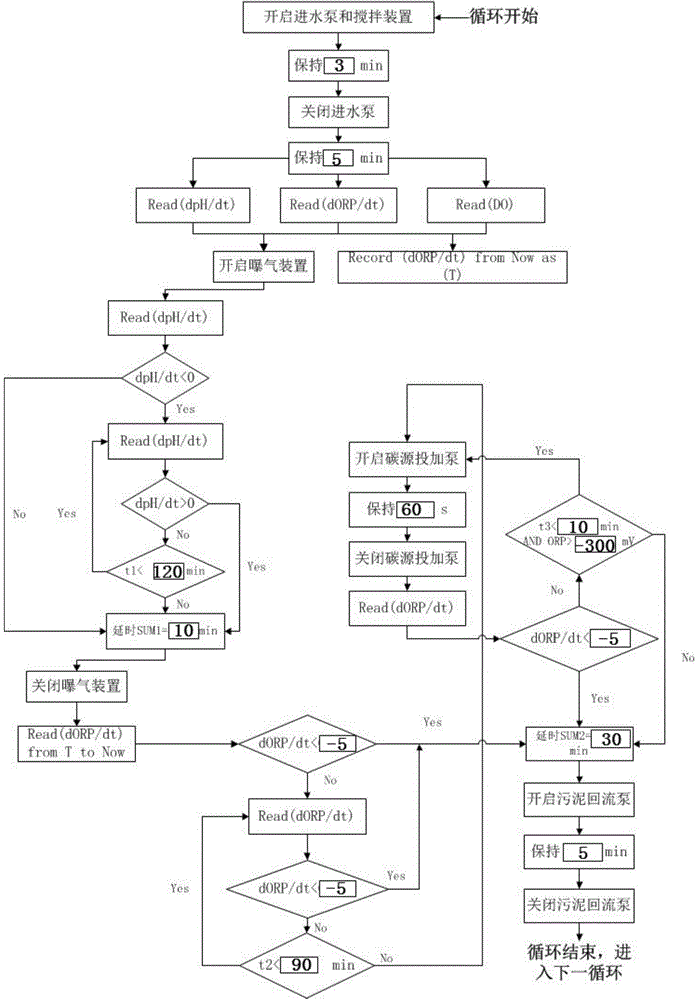

[0081] Such as figure 1 As shown, the device for treating high ammonia nitrogen wastewater of the present invention includes a water inlet system, a reaction system, an aeration system, a carbon source dosing system, a water outlet system and a real-time control system;

[0082] Described reaction system comprises a reactor, and described reactor is a container with cover, is divided into three parts, is successively anoxic pool (2.0), aerobic pool (3.0) and membrane separation pool (4.0):

[0083] An agitator (2.1) is provided above the anoxic pool, a sampling valve 1 (2.2) is provided on the side wall of the anoxic pool, a reflux liquid inlet (2.3) is provided at the bottom of the side wall, and a ORP probe (2.4);

[0084] An overflow weir (3.1) is provided between the anoxic pool and the aerobic pool, and a pH probe (3.2), a dissolved oxygen DO probe (3.3), a sampling valve 2 (3.4) and a dra...

Embodiment 2

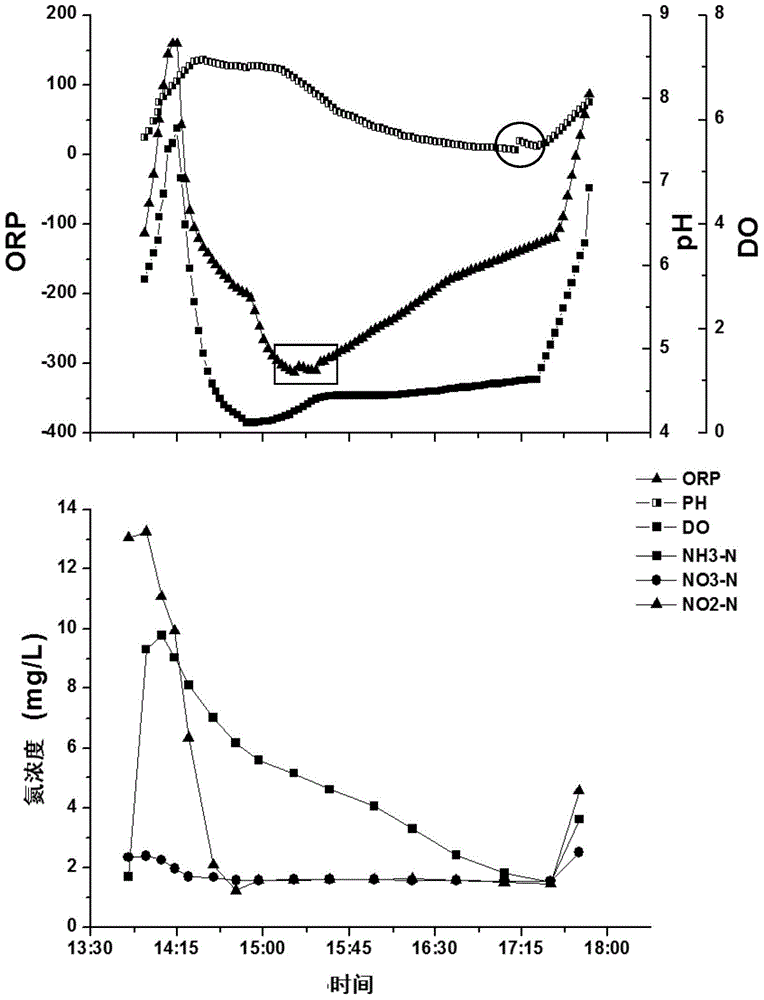

[0092] Embodiment 2, using A / O MBR semi-continuous operation process to treat livestock and poultry breeding wastewater

[0093] Using the device in Example 1 to treat a certain intensive livestock and poultry breeding wastewater, the temperature of the reactor is controlled at 25 ± 0.5 ° C, including the following steps:

[0094] Inoculate the return sludge of urban sewage treatment plant with a concentration of 5500mg / L into the anoxic pool and the aerobic pool, turn on the agitator, aeration system I (aeration flow rate of 2L / min), aeration system II (aeration The flow rate is 10L / min, and the aeration rate for the entire membrane flushing is set according to two membranes), the water inlet pump and the implementation control system adopt the method of gradient water (sewage) inlet, so that the sludge concentration gradually increases to 8500-9500mg / L, Gradient water inflow control is as follows: the first stage is 7 days, the influent water is diluted to 1 / 4 of the origin...

Embodiment 3

[0110] Embodiment 3, using A / O MBR semi-continuous operation process to treat landfill leachate

[0111] Using the device in Example 1 to treat a certain landfill leachate, the temperature of the reactor is controlled at 25 ± 0.5 ° C, including the following steps:

[0112] Inoculate the return sludge of urban sewage treatment plant with a concentration of 5500mg / L into the anoxic pool and the aerobic pool, turn on the agitator, aeration system I (aeration flow rate of 1.5L / min), aeration system II (aeration The air flow rate is 15L / min), the water inlet pump and the implementation control system adopt the gradient water (sewage) method to gradually increase the sludge concentration to 6500-7500mg / L, and the gradient water inlet control is as follows: the first stage is 7 On the 7th, the incoming water is diluted to 1 / 4 of the concentration of the original sewage. The second stage is 7 days, and the incoming water is diluted to 1 / 2 of the original sewage concentration. The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com