Flat and round cutter and manufacturing method thereof

A manufacturing method, the technology of flat circle, applied in the field of flat round knife and its manufacturing, can solve the problems of short service life, poor toughness, low stability, etc., and achieve the effect of long service life, small wear amount and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

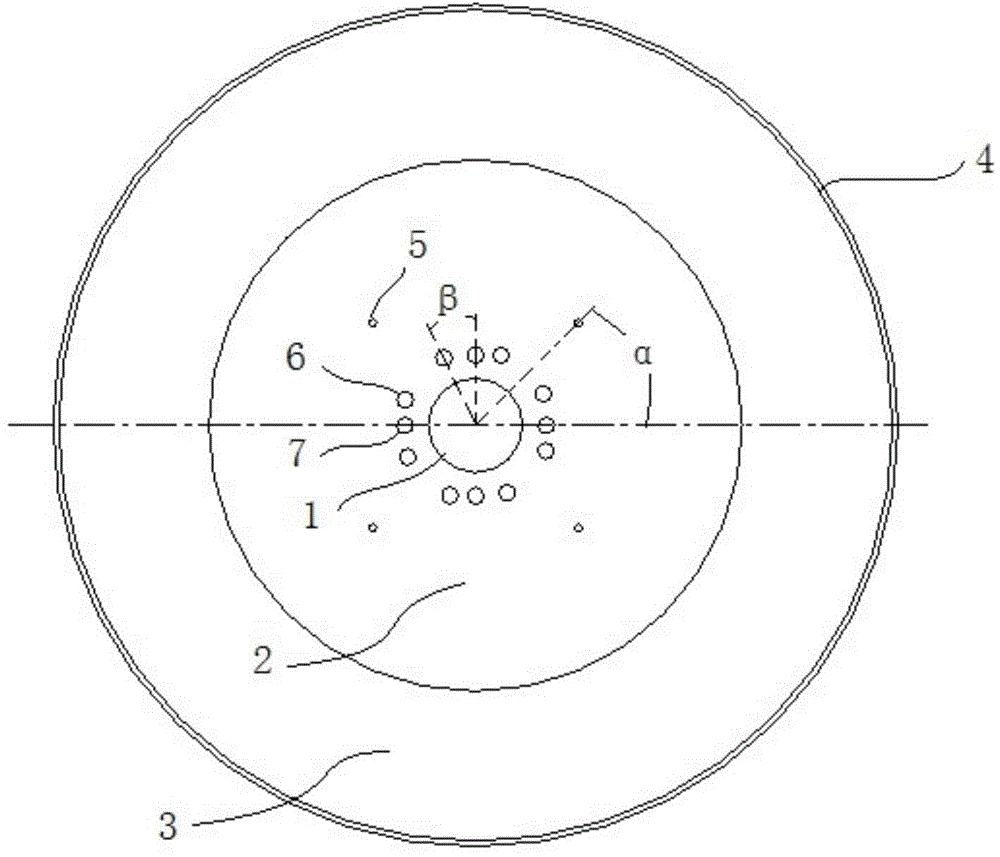

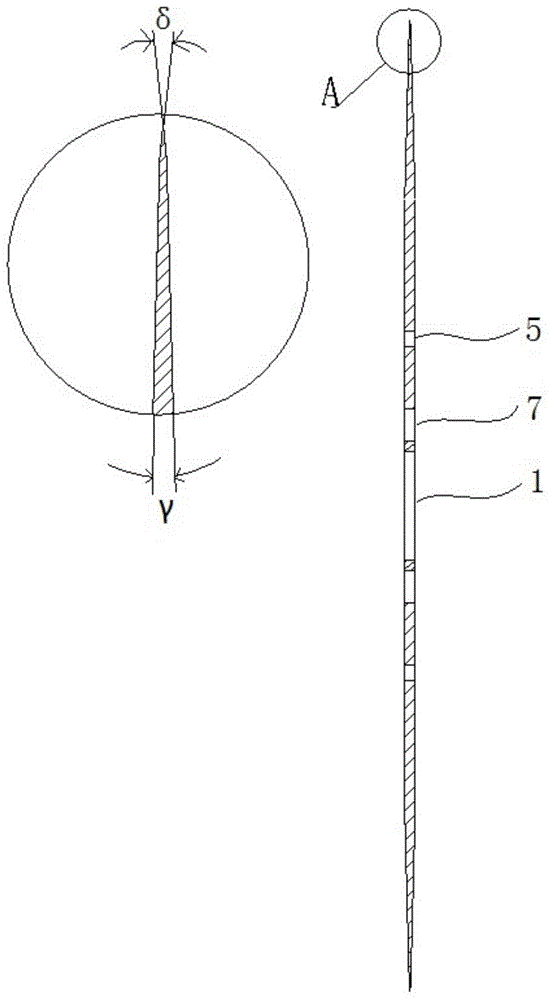

[0048] Such as figure 1 and figure 2 As shown, a flat round knife is shaped as a circular blade with an outer circle size of 610 mm, including a central hole 1, a cutter head 2 and a blade 3, the center hole 1 is located at the center of the cutter head 2, and the blade 3 is located at the center of the cutter head On the outer ring of 2, the outer ring of the blade 3 is provided with a blade edge 4, the blade angle δ of the blade edge 4 is 15°, and the length of the blade edge is 3mm; the angle γ of the blade 3 is 1.42°; Degree ≤ 0.001. The cutterhead 2 is provided with threaded holes 5, the first mounting hole 6 and the second mounting hole 7, and there are four threaded holes 5, the length of which is 101.5 mm from the center of the flat circular knife; the first mounting holes 6 have eight, the distance The length of the flat circular knife center is 54mm, and the second mounting hole 7 has four, and the length apart from the flat circular knife center is 51mm. The ang...

Embodiment 2

[0071] Such as figure 1 and figure 2 Shown, a kind of flat circular knife, its shape is the annular blade, comprises center hole 1, cutter head 2 and blade 3, and center hole 1 is positioned at the center of cutter head 2, and blade 3 is positioned at the outer ring of cutter head 2, The outer ring of the blade 3 is provided with a blade edge 4, the blade angle δ of the blade edge 4 is 13°, and the length of the blade edge is 3mm; the angle γ of the blade 3 is 1.25°; the parallelism of the cutter head 2 is ≤0.001. The cutterhead 2 is provided with threaded holes 5, the first mounting hole 6 and the second mounting hole 7, and there are four threaded holes 5, the length of which is 101mm apart from the center of the flat circular knife; The length of the center of the round knife is 53.5mm, and the second mounting hole 7 has four, and the length of the center of the flat circle knife is 50.5mm. The angle α between the line connecting the threaded hole 5 and the center of the...

Embodiment 3

[0094] Such as figure 1 and figure 2 Shown, a kind of flat circular knife, its shape is the annular blade, comprises center hole 1, cutter head 2 and blade 3, and center hole 1 is positioned at the center of cutter head 2, and blade 3 is positioned at the outer ring of cutter head 2, The outer ring of the blade 3 is provided with a blade edge 4, the blade angle δ of the blade edge 4 is 18°; the angle γ of the blade 3 is 1.60°; the parallelism of the cutter head 2 is ≤0.002. The cutter head 2 is provided with threaded holes 5, the first mounting hole 6 and the second mounting hole 7, and there are four threaded holes 5, the length of which is 102mm apart from the center of the flat circular cutter; The length of the center of the round knife is 54.5mm, the second mounting hole 7 has four, and the length of the center of the flat circle knife is 51.5mm, and the threaded holes 5, the first mounting hole 6 and the cutter head 2 are evenly distributed. The angle α between the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com