Thread cutting insert for thread turning processing and external thread component manufacturing method

A technology for cutting inserts and cutting threads, applied in thread cutting tools, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient size and damage to the precision of the machined surface, and achieve the improvement of cutting edge strength and cutting edge strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

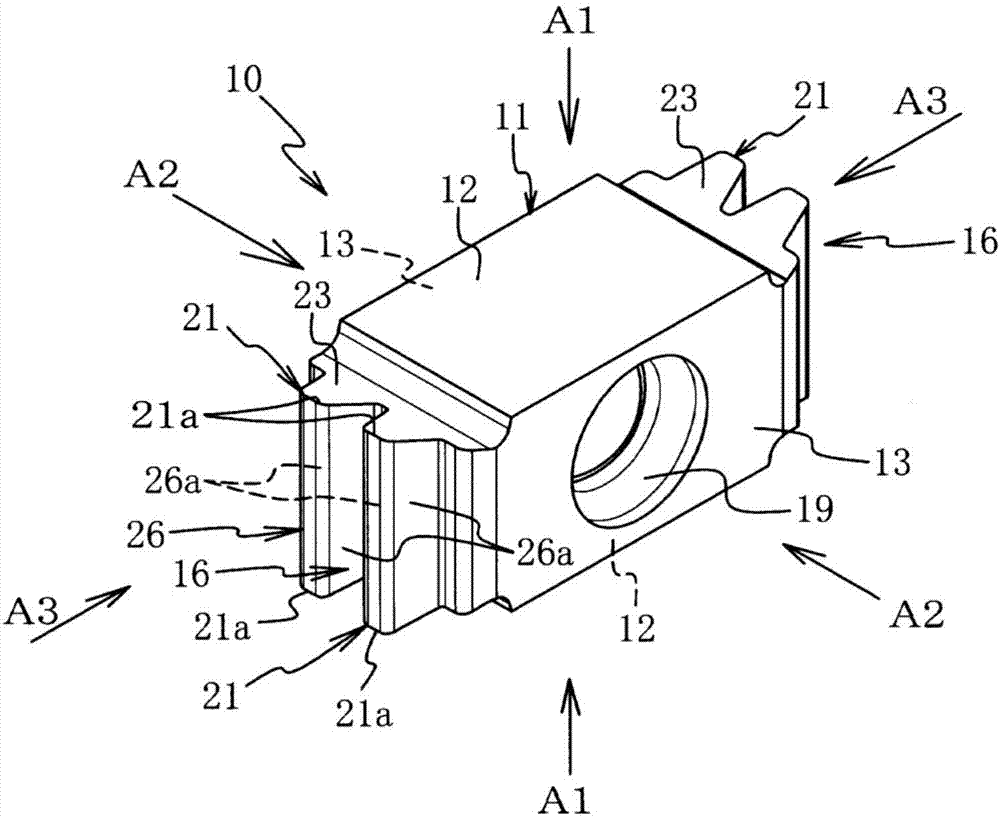

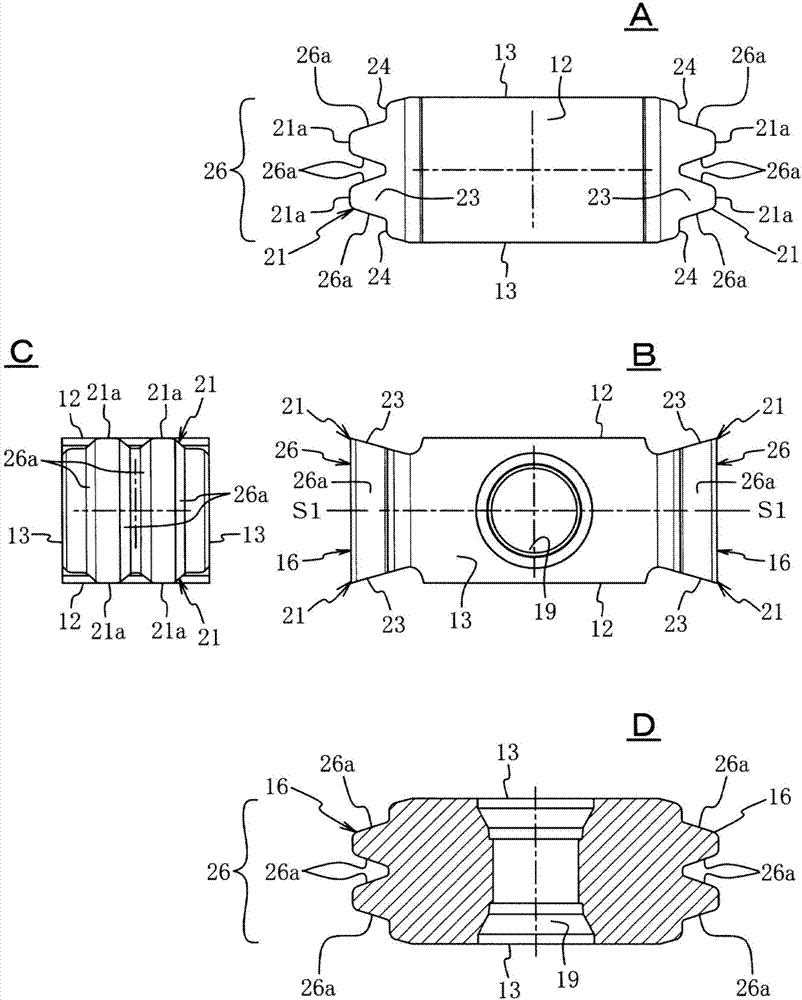

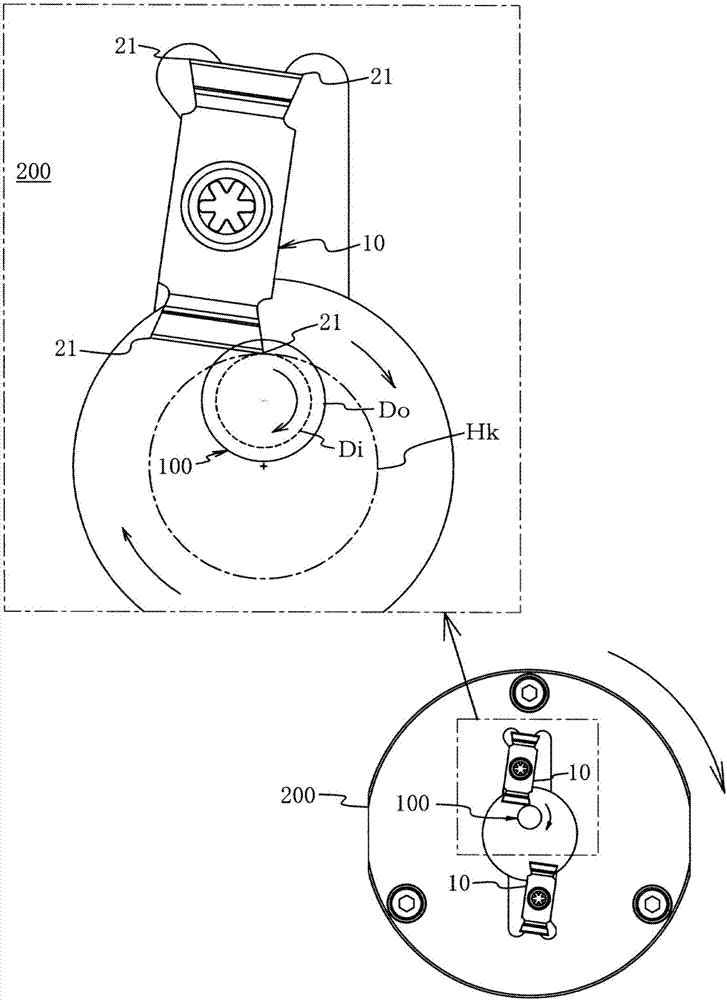

[0044] refer to Figure 1 to Figure 5 An embodiment example in which the cutting insert for thread cutting in thread turning machining according to the present invention is embodied will be described. Among them, such as Figure 5 As shown, for the cutting insert (non-regrinding cutting insert) 10 of this example, the thread (thread thread) to be formed is a triangular thread with a slightly flat top (top) (the angle of the thread thread is 40 degrees) , the threaded thread 105 is left-right symmetrical on a section passing through the axis Gn of the shaft member 100 (left-right symmetrical with respect to the central axis Yc in the width direction of the threaded thread 105), and the cutting insert 10 is used to process a thread by one feed The groove is trapezoidal and the width in the lead direction is larger than the two threads of the thread teeth. Therefore, if figure 1 , figure 2 As shown, the shape (cutting edge shape) of the cutting insert 10 when viewing the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com