Particle material rotary valve

A rotary valve, granular material technology, used in conveying bulk materials, conveyors, transportation and packaging, etc., can solve problems such as difficulty in obtaining continuous and stable work or shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

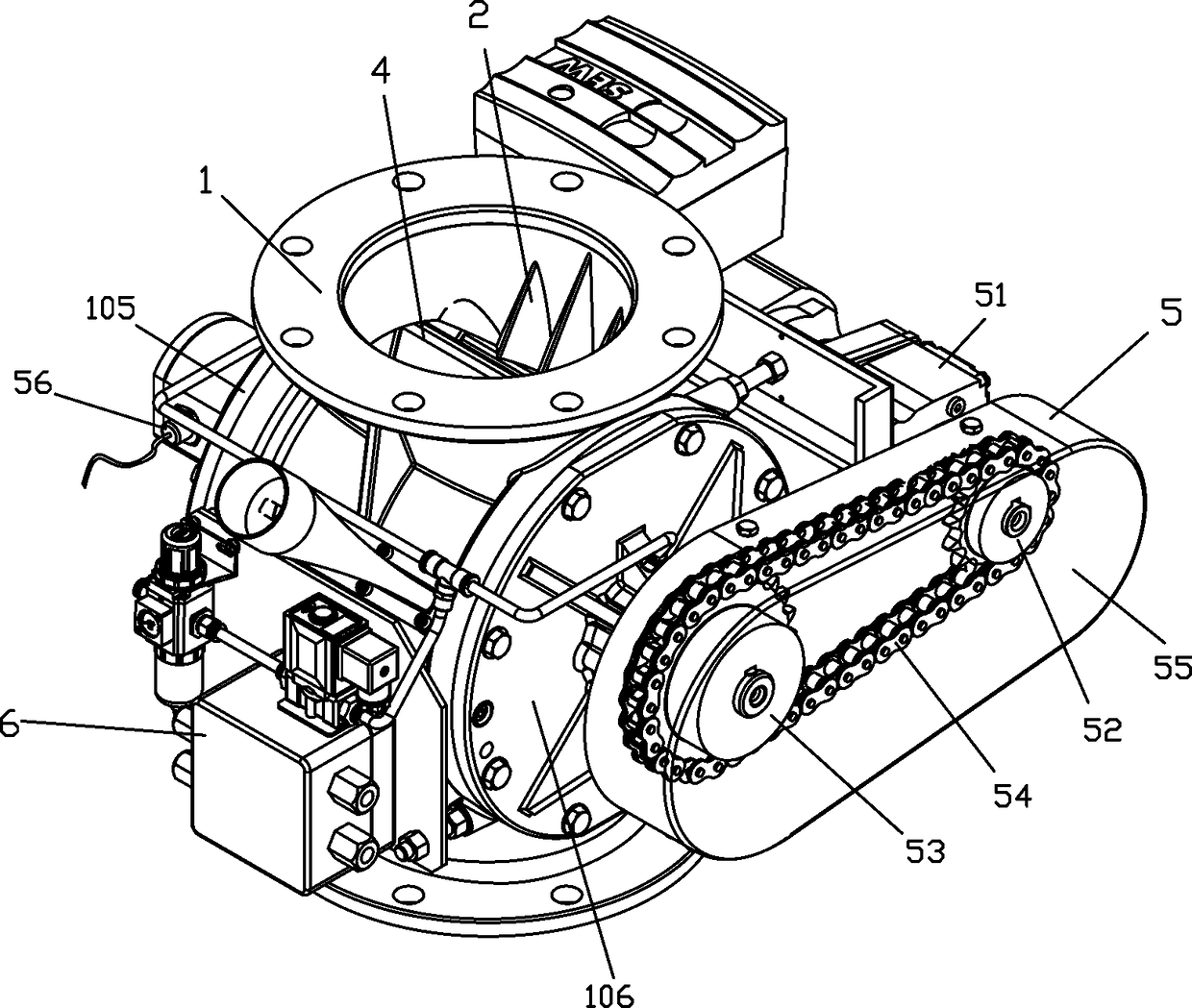

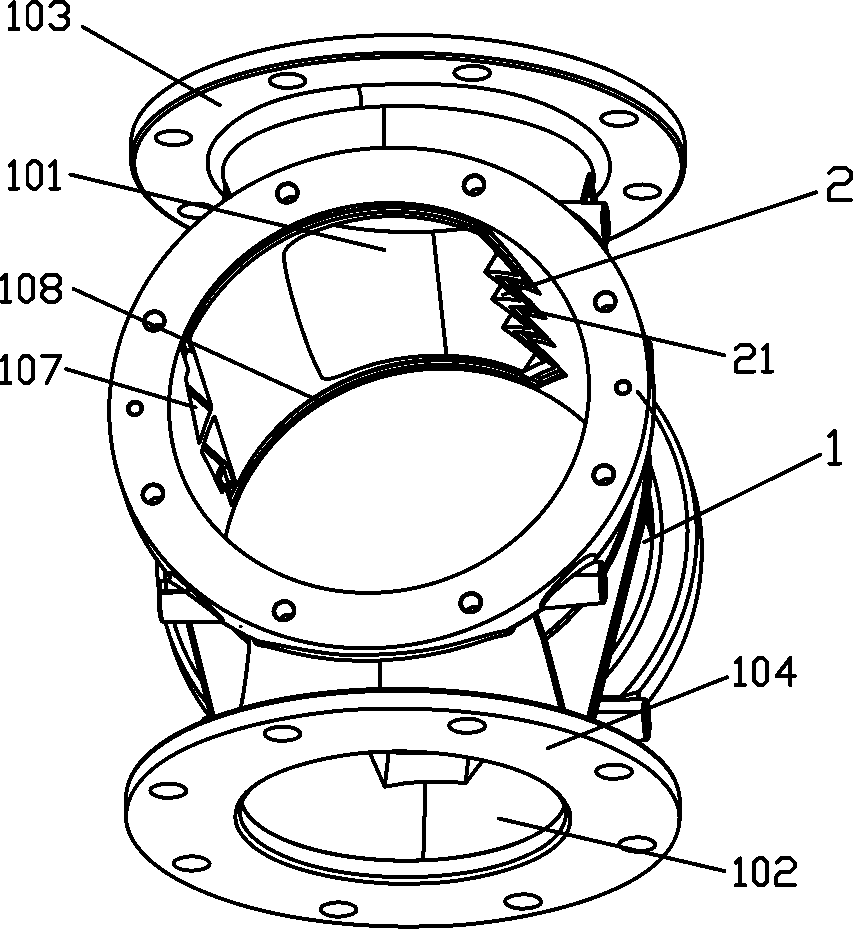

[0018] see Figure 1 ~ Figure 4 , a granular material rotary valve of the present invention, which includes,

[0019] The valve body 1 is a four-way structure with a valve cavity in the middle, which is cylindrical. Ports are provided with end plates 105, 106, and shaft holes are arranged in the middle of the end plates; one side of the inner wall of the valve body 1 side of the feed port 101 is provided with a number of cutting teeth 2, and the other side is provided with an exhaust port 107. The bottom surface of the cutting tooth 2 is provided with an exhaust groove 21, and the upper part of the inner wall of the valve body 1 is provided with an exhaust passage 108 connecting the exhaust port 107 and the exhaust groove 21; the discharge port 102 of the valve body 1 is connected to the exhaust port 107 The inner wall of the same side is protrudingly provided with cutting teeth 3;

[0020] The rotor 4 has a star-shaped structure, including a central shaft 41 and a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com