Method for manufacturing floating gate discharging sharp corner

A manufacturing method and floating gate technology, applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as poor stability and flash memory erasing speed limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

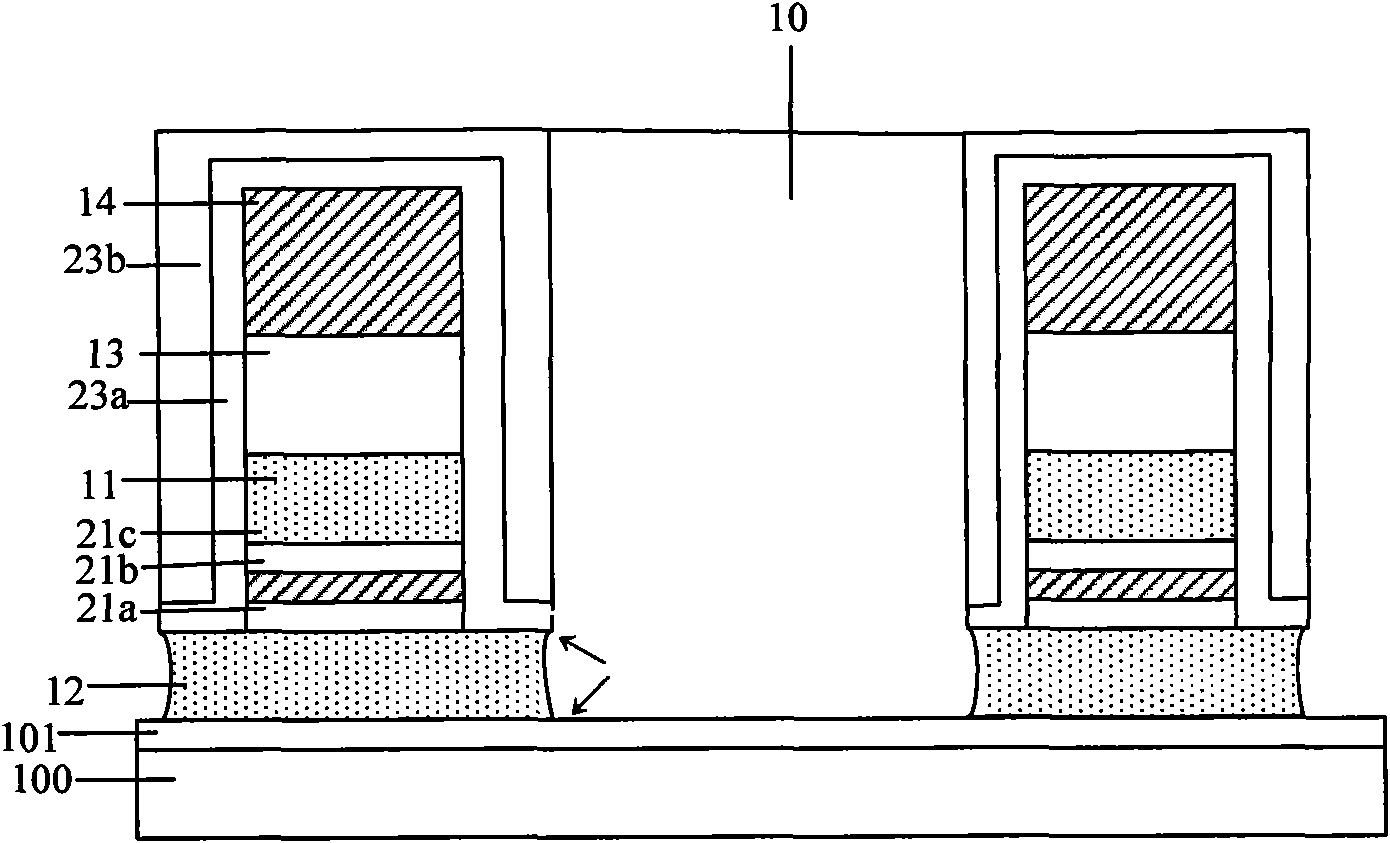

[0030] Refer below Figure 2 to Figure 7 The specific content of this embodiment will be described in detail. The manufacturing steps of the floating gate discharge peak of the present embodiment include:

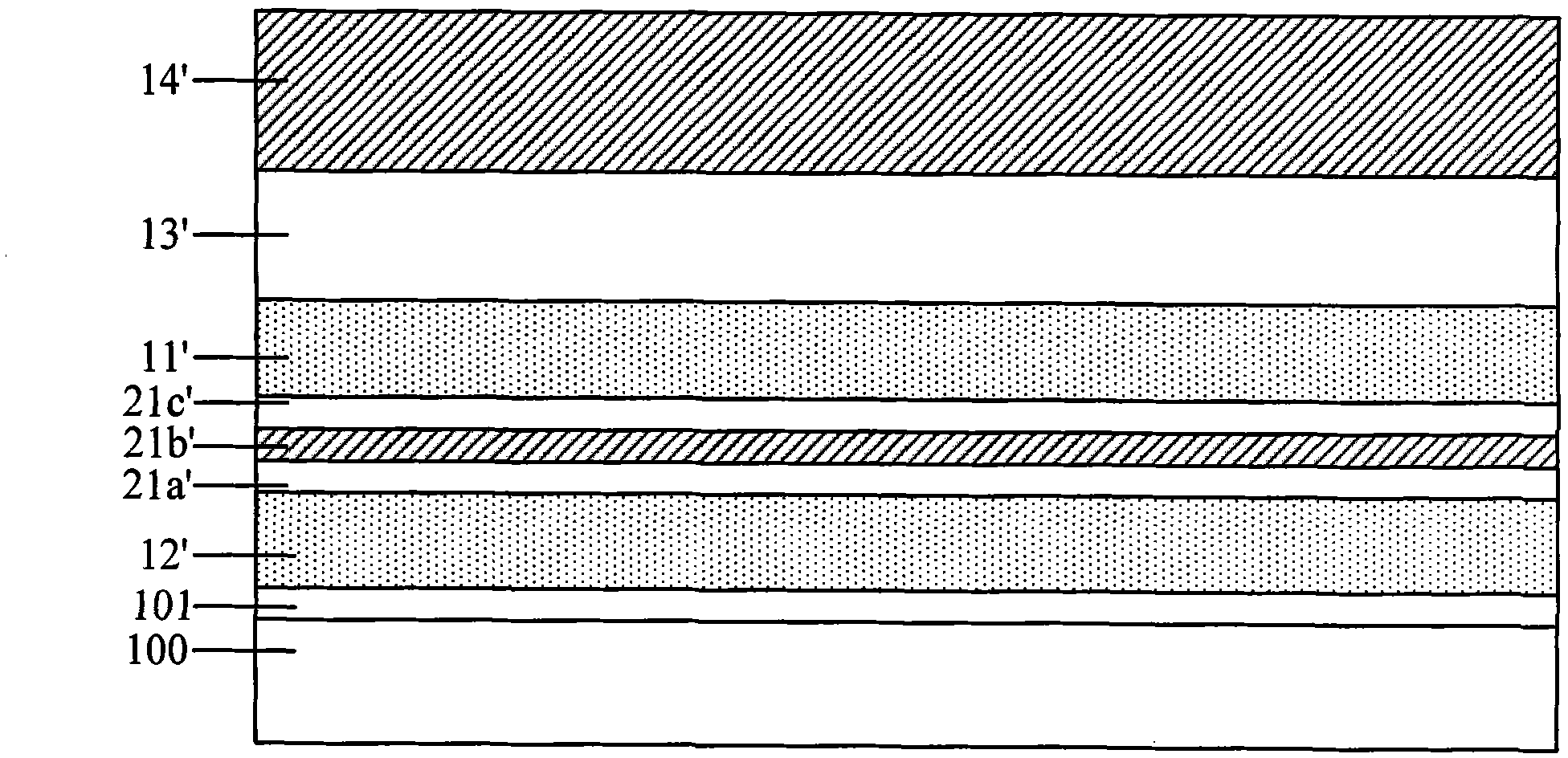

[0031] Step 1: See figure 2 As shown, a first oxide layer 101, a floating gate layer 12', a first silicon oxynitride layer 21a', a second oxide layer 21b', a second silicon oxynitride layer 21c', and a control gate layer are sequentially formed on a substrate 100. 11', the third oxide layer 13', and the third silicon oxynitride layer 14'; wherein, the materials of the first oxide layer 101, the second oxide layer 21b', and the third oxide layer 13' can be but not limited to silicon oxide.

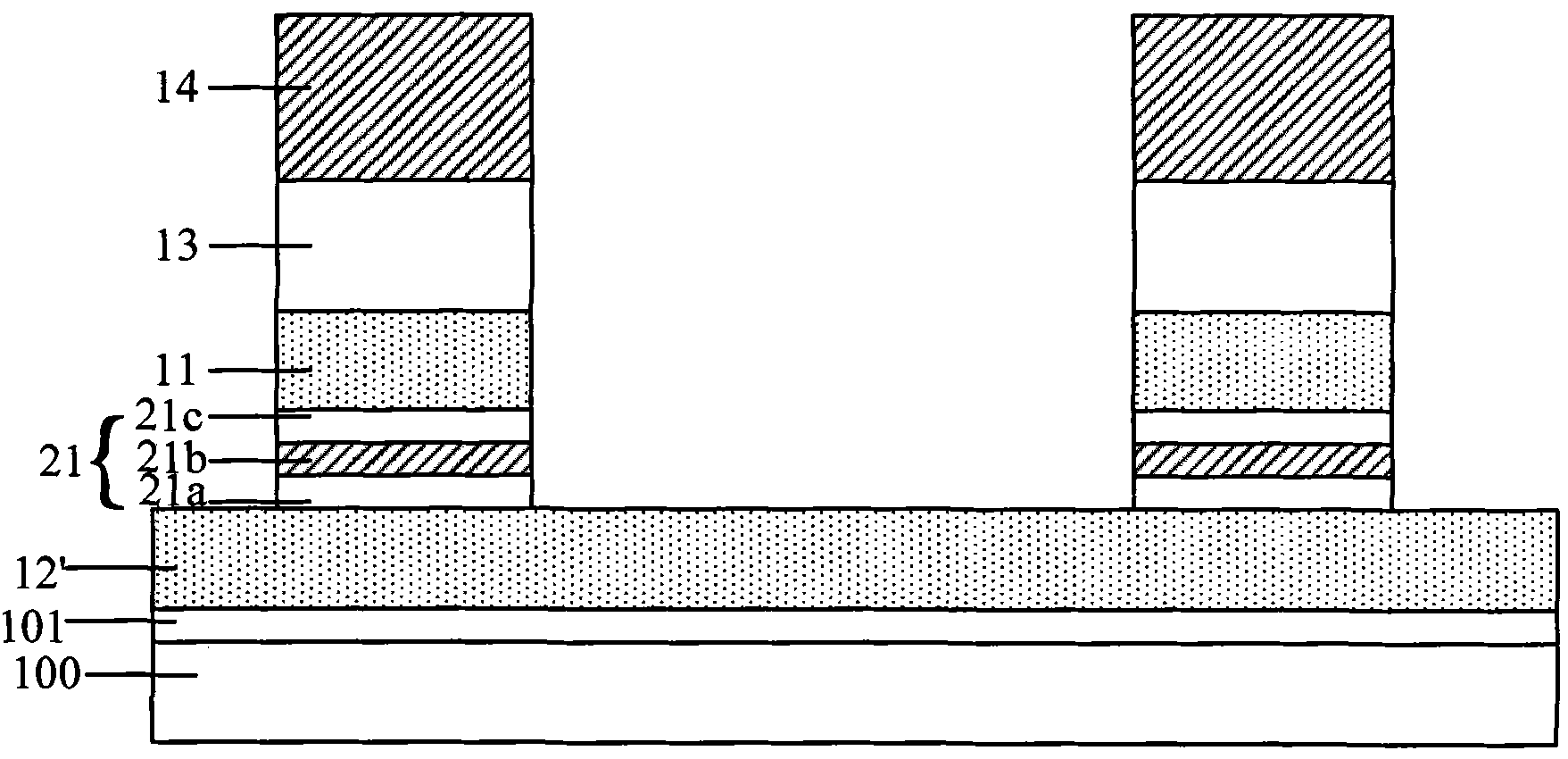

[0032] Step 2: see image 3 As shown, for the first silicon oxynitride layer 21a', the second oxide layer 21b', the second silicon oxynitride layer 21c', the control gate layer 11', the third oxide layer 13', the third silicon oxynitride layer 14' for masking and etching to form th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com