Nanocomposite catalyst for ethane oxidative dehydrogenation reaction and preparing method thereof

A nanocomposite and oxidative dehydrogenation technology is applied in the field of nanocomposite catalysts and their preparation, which can solve the problems of far-flung industrialization requirements of catalyst production capacity, loss of quality, and expensive chemical raw materials, etc. The effect of uniform distribution, improved catalytic activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the nanocomposite catalyst provided by the present invention can be prepared by the following two methods: the sol-gel method and the physical mixing method.

[0028] The specific steps of preparing the ethane oxidation dehydrogenation reaction nanocomposite catalyst by the sol-gel method adopted in the present invention include:

[0029] 1) dissolving cerium nitrate and citric acid with a molar ratio of 1:1 to 1:4 in deionized water, and carrying out a constant temperature oil bath, the temperature of the oil bath is 50 to 80°C, and the oil bath time is 16 to 32 hours, Get CeO 2 Cerium oxide sol with a mass fraction of 5-30%;

[0030] 2) Put the M1 pure-phase compound in the molybdenum vanadium niobium tellurium multi-metal oxide system and the cerium oxide sol obtained in step 1) according to the mass ratio of 1:1 to 1:4 in a water bath at 50 to 70°C Mix evenly for 1 to 3 hours;

[0031] 3) Dry the mixture obtained in step 2), and bake it ...

Embodiment 1

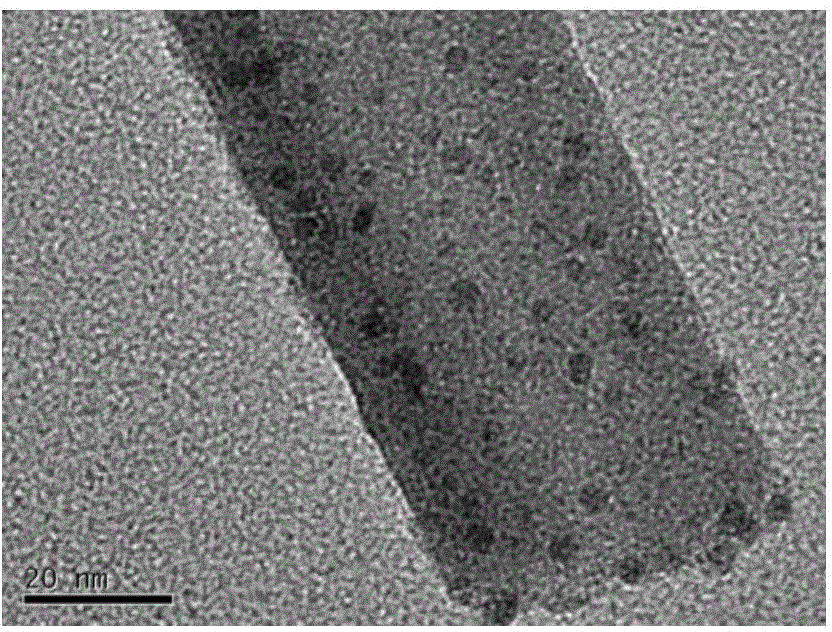

[0044] M1 pure phase compound and CeO in a molybdenum vanadium niobium tellurium multi-metal oxide system 2 Nanocomposite catalyst, CeO in nanocomposite catalyst 2 The mass fraction of nanoparticles is 20wt.%, and its particle size is 20nm. The atomic ratio of molybdenum, vanadium, niobium, and tellurium in the molybdenum, vanadium, niobium, and tellurium multi-metal oxides in the catalyst is 1:0.20:0.30:0.10, and the particles The diameter is 75nm and the particle length is 225nm.

[0045] The M1 pure phase compound and CeO in the above molybdenum vanadium niobium tellurium multi-metal oxide system 2 The nanocomposite catalyst preparation method is as follows:

[0046] Under the condition of water bath at 80°C, mix and dissolve ammonium molybdate, vanadyl sulfate, and telluric acid in deionized water with the atomic ratio of molybdenum, vanadium, and tellurium being 1:0.26:0.25 to obtain solution A, and dissolve ammonium niobium oxalate in deionized water. Solution B is ob...

Embodiment 2

[0052] M1 pure phase compound and CeO in a molybdenum vanadium niobium tellurium multi-metal oxide system 2 Nanocomposite catalyst, CeO in nanocomposite catalyst 2 The mass fraction of nanoparticles is 20wt.%, and its particle size is 5nm. The atomic ratio of molybdenum, vanadium, niobium, and tellurium in the molybdenum, vanadium, niobium, and tellurium multi-metal oxides in the catalyst is 1:0.19:0.28:0.08, and the particles The diameter is 40nm and the particle length is 200nm.

[0053] The M1 pure phase compound and CeO in the above molybdenum vanadium niobium tellurium multi-metal oxide system 2 The nanocomposite catalyst preparation method is as follows:

[0054] Under the condition of water bath at 80°C, mix and dissolve ammonium molybdate, vanadyl sulfate, and telluric acid in deionized water with the atomic ratio of molybdenum, vanadium, and tellurium being 1:0.25:0.23 to obtain solution A, and dissolve ammonium niobium oxalate in deionized water. Solution B is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com