Method for preparing oxygen carrier by using vanadium-titanium magnetite, and applications of oxygen carrier

A technology for vanadium-titanium magnetite and vanadium-titanium magnetite concentrate, which is applied in the fields of efficient comprehensive utilization of mineral resources and energy chemistry, can solve problems such as inability to directly produce pure hydrogen, and achieves superior performance, easy large-scale production, high efficiency and cleanliness The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for preparing oxygen carrier with vanadium titanomagnetite, its specific steps are as follows:

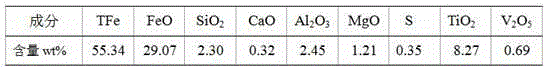

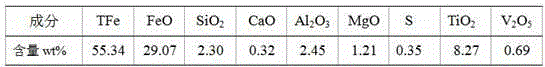

[0033] (1) First, dry the vanadium-titanium magnetite concentrate at 380°C for 5 hours to remove moisture in the ore, and then crush it to a particle size of 0.42mm. Take 2kg of the dried vanadium-titanium magnetite concentrate, add 0.8kg of modifier, and put it in the air Or calcined in an oxygen-enriched atmosphere for 40 hours, and the calcining temperature was controlled at 950 ° C. The components of the vanadium-titanium magnetite concentrate were shown in Table 1. The modifier was CaO, and the amount of modifier added was the mass of the vanadium-titanium magnetite concentrate after drying. 40% of

[0034] Table 1

[0035]

[0036] (2) The vanadium-titanium magnetite concentrate treated in step (1) is added to the carrier, active components and additives and mixed uniformly to obtain a mixture. After the mixture is conventionally shaped, it is made into ...

Embodiment 2

[0039] The method for preparing oxygen carrier with vanadium titanomagnetite, its specific steps are as follows:

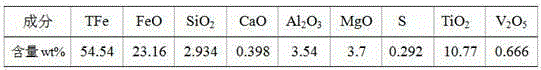

[0040] (1) First, dry the vanadium-titanium magnetite concentrate at 100°C for 36 hours to remove the moisture in the ore, and then crush it to a particle size of 0.50mm. Take 2kg of the dried vanadium-titanium magnetite concentrate, add 0.3kg of modifier, and put it in the air Or calcined in an oxygen-enriched atmosphere for 12 hours, and the calcining temperature was controlled at 1300°C. The composition of the vanadium-titanium magnetite concentrate was shown in Table 2. The modifier was a mixture of MgO and BaO with a mass of 1:1, and the amount of the modifier added was vanadium 15% of the mass of titanium magnetite concentrate after drying;

[0041] Table 2

[0042]

[0043] (2) The vanadium-titanium magnetite concentrate treated in step (1) is added to the carrier, active components and additives and mixed evenly to obtain a mixture. After the mixture i...

Embodiment 3

[0046] The method for preparing oxygen carrier with vanadium titanomagnetite, its specific steps are as follows:

[0047] (1) First, dry the vanadium-titanium magnetite concentrate at 280°C for 16 hours to remove moisture in the ore, and then crush it to a particle size of 0.35mm. Take 2kg of the dried vanadium-titanium magnetite concentrate, add 0.55kg of modifier, and put it in the air Or calcined in an oxygen-enriched atmosphere for 25 hours, and the calcining temperature was controlled at 1100 ° C. The composition of the vanadium-titanium magnetite concentrate is shown in Table 3, the modifier is BaO, and the amount of modifier added is the mass of the vanadium-titanium magnetite concentrate after drying. 27.5% of

[0048] table 3

[0049]

[0050] (2) The vanadium-titanium magnetite concentrate treated in step (1) is added to the carrier, active components and additives and mixed uniformly to obtain a mixture. After the mixture is conventionally formed, it is made int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com