Cobaltosic oxide dodecahedron/carbon nitride nanosheet composite and application thereof in waste gas treatment

一种四氧化三钴、十二面体的技术,应用在化学/物理过程、金属/金属氧化物/金属氢氧化物催化剂、气体处理等方向,达到增强可见光响应范围、制备工艺简单、原料丰富易得的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

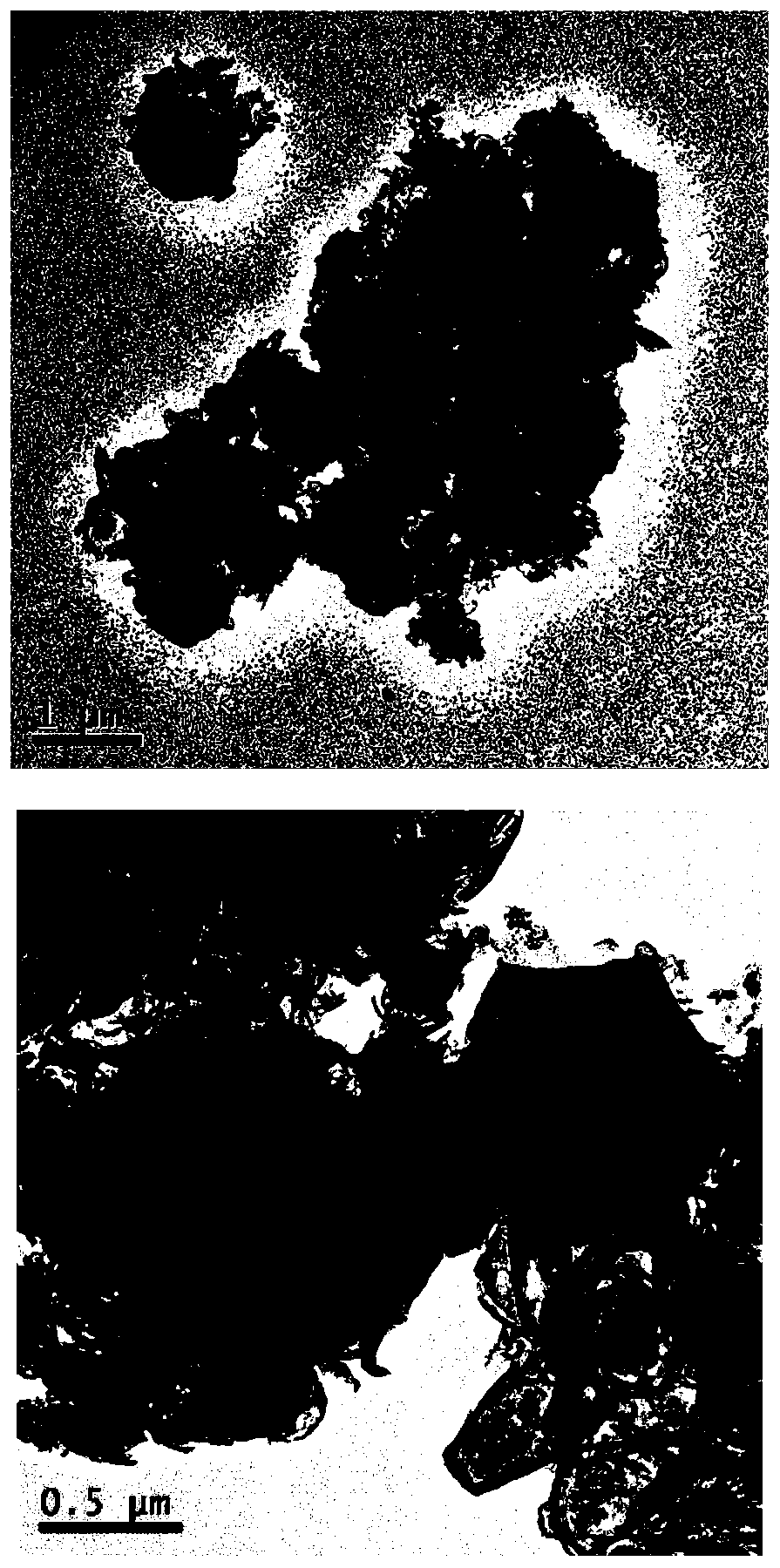

[0033] The invention discloses a method for preparing a visible light-responsive cobalt tetroxide dodecahedron / carbon nitride nanosheet composite, which comprises the following steps:

[0034] (1) Take urea as the precursor and calcinate twice to obtain carbon nitride nanosheets;

[0035] (2) Disperse the carbon nitride nanosheets in methanol, sequentially add cobalt nitrate hexahydrate and 2-methylimidazole, and react to obtain a carbon nitride nanosheet composite;

[0036] (3) The carbon nitride nanosheet composite is calcined at low temperature in an air atmosphere to obtain the cobalt tetroxide dodecahedron / carbon nitride nanosheet composite.

Embodiment 1

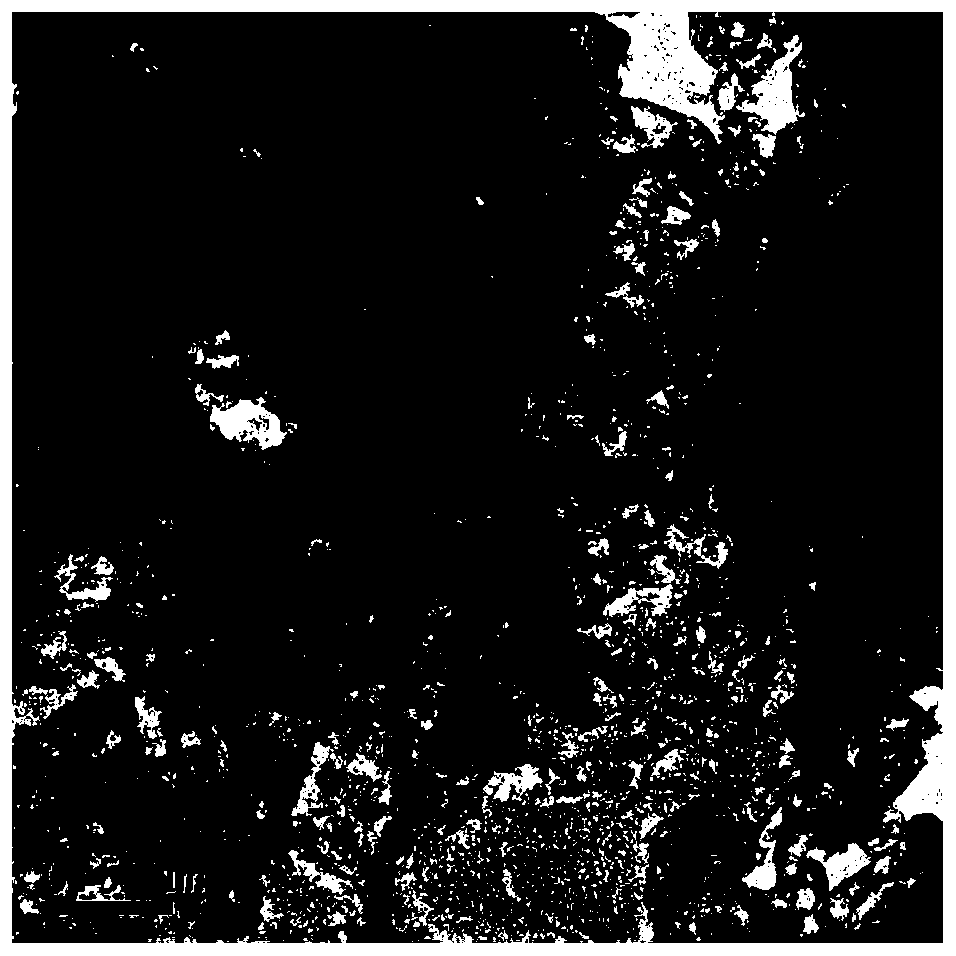

[0038] The specific steps for the preparation of carbon nitride nanosheets are as follows: put 30 g of urea in a crucible with a lid, calcine in a muffle furnace air atmosphere, heat up to 550 ℃ at a heating rate of 2.5 ℃ / min, calcination time is 4 hours, annealing Afterwards, a block of carbon nitride is obtained; the block of carbon nitride is placed on the bottom of a square porcelain boat without a cover, and then calcined in the air atmosphere of a muffle furnace at a heating rate of 5°C / min to 500°C, The calcination time is 2h, and the present invention obtains pleated carbon nitride nanosheets after high temperature calcination twice; figure 1 TEM image of carbon nitride nanosheets.

Embodiment 2

[0040] The specific steps for preparing the carbon nitride nanosheet composite are as follows:

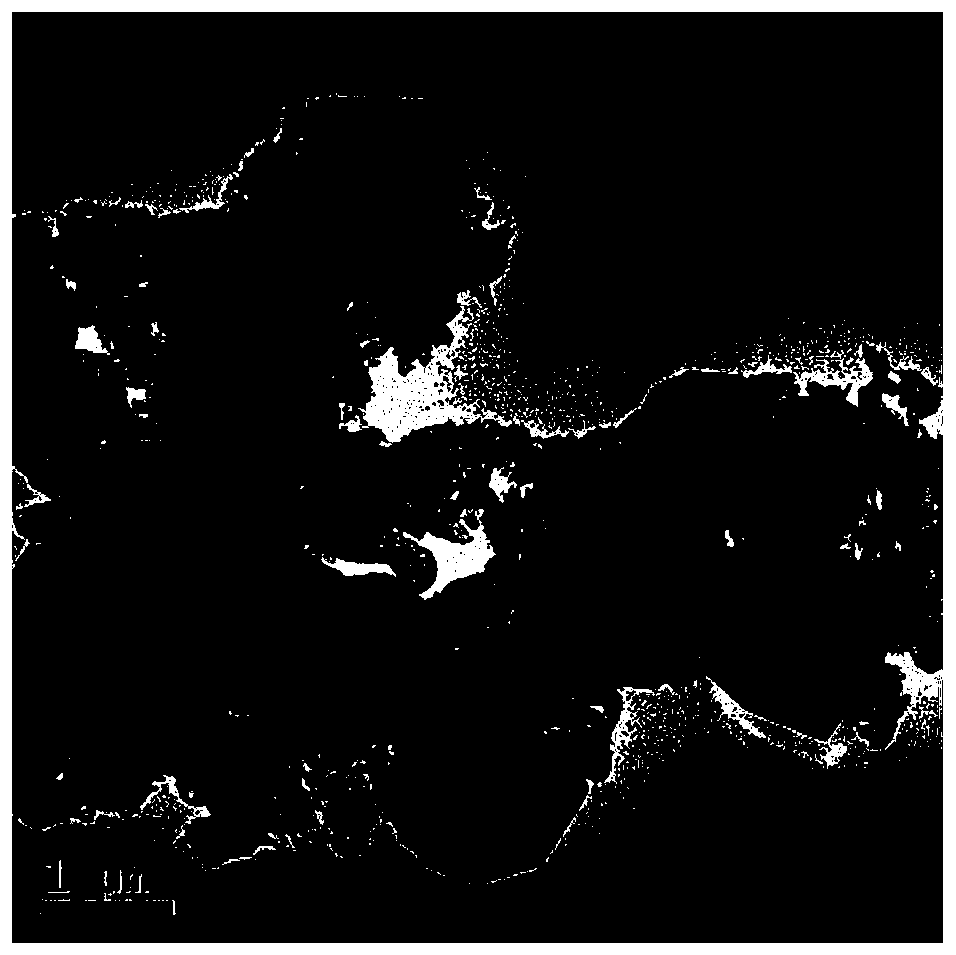

[0041] The carbon nitride nanosheet composite was synthesized by in-situ growth method. Disperse 0.06g of carbon nitride nanosheets uniformly in 15ml methanol for 30min ultrasonic treatment, then add 5ml of cobalt nitrate hexahydrate methanol solution (12mg / ml) into the suspension of carbon nitride nanosheets and continue ultrasonic treatment for 30min , To obtain a suspension of carbon nitride nanosheets combined with divalent cobalt ions. Afterwards, 2-methylimidazole methanol solution (5ml, 18mg / ml) was slowly poured into the above suspension, and the mixture was magnetically stirred at room temperature for 1 hour, and then left to stand for 24 hours. Finally, the purple product carbon nitride nanosheet composite obtained after centrifugation was washed three times with methanol and dried at 60°C overnight (24 hours), and collected for the preparation of cobalt tetroxide dodecahed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com