Laser remelting method for steel electric arc spraying aluminum coating layer used for ocean platform

A technology of arc spraying and offshore platform, which is applied in the direction of coating, metal material coating process, fusion spraying, etc. It can solve the problems of affecting the mechanical properties of load-bearing devices, reducing the service life, and accelerating the corrosion rate, etc., to achieve long-term protection, The effect of uniform thickness and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

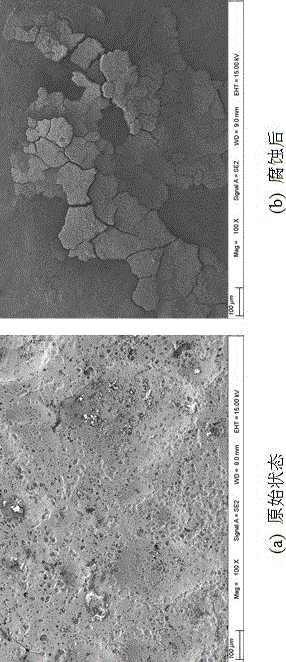

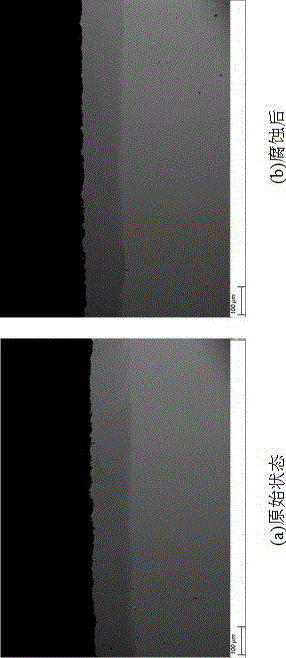

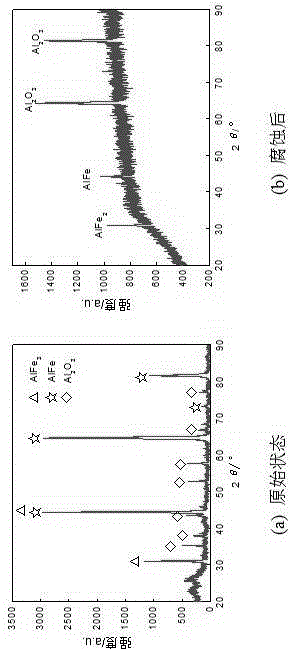

[0009] (1) use 180 # -1000 # Grind the surface of the substrate with sandpaper, clean it with absolute ethanol, and degrease with acetone to remove the grease and sundries on the surface of the sample to ensure that the surface cleanliness of the substrate reaches Sa3 level.

[0010] (2) Use cast iron sand with a particle size of 1mm as abrasive grains, compressed air pressure > 0.8MPa, sandblasting distance of 200mm, and sandblasting angle of 20°, so that the roughness can reach RZ60μm.

[0011] (3) Use industrial Ф2mm aluminum wire as raw material to ensure its purity > 99.5%, use the heat energy of the arc to heat the aluminum wire to a molten state, the working voltage is 20-32V, the current is 150-300A, and the temperature is 0.5-0.6Mpa The high-pressure airflow is used as the power to spray molten aluminum onto the surface of the substrate, ensuring that the moving speed of the spray gun is 300-400mm / s, and the spraying distance is 5-8mm. After the spraying is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com