Na doping method of CIGS (copper, indium, gallium and selenium) and manufacturing method of Na-doped CIGS sputtering target material

A doping amount and compound technology, applied in the field of solar cells, can solve the problems of Na loss, long doping time, uneven doping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

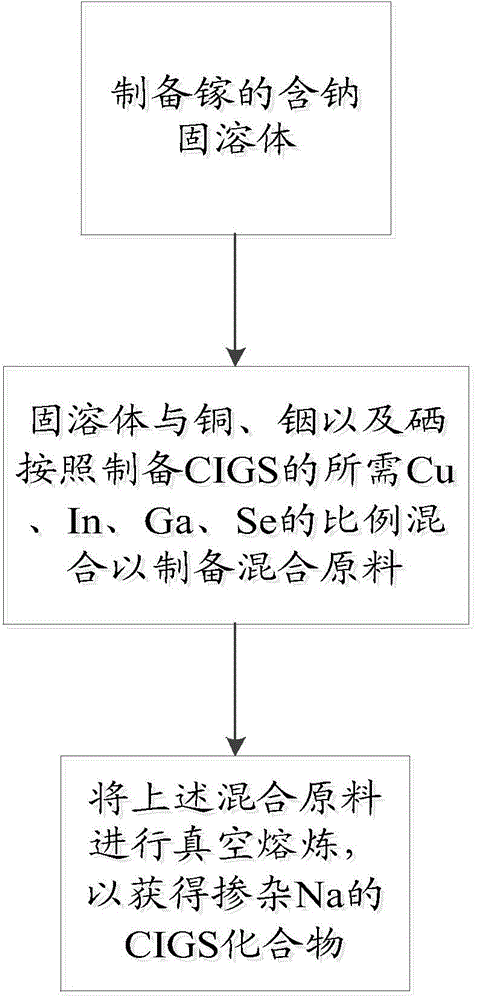

Method used

Image

Examples

Embodiment 1

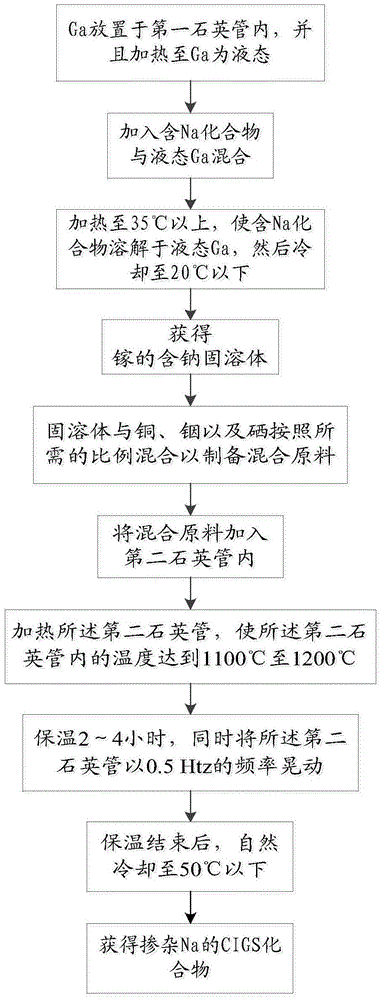

[0039] The present embodiment provides a kind of Na doping method of CIGS, it comprises the following steps:

[0040] Step 1, preparing a Na-containing solid solution of Ga.

[0041] First, according to the weight ratio Ga 92.2%, Na 2 SeO 3 7.8% weighed Ga and Na 2 SeO 3 . Then, Ga was placed in the container. In order to improve the quality of the final compound product of CIGS doped with Na, Ga, Na 2 SeO 3 Both adopt a purity of more than 99.99%, and the container adopts a quartz tube. Next, the container is heated to liquefy Ga. In this embodiment, the temperature of Ga in the container is 35°C, and then the Na 2 SeO 3 Added to the container to make liquid Ga and Na 2 SeO 3 mix. Preferably, Na 2 SeO 3 For powder, shake the container to make Ga liquid and Na 2 SeO 3 The solids were mixed well. Finally, heat the mixture in the container to above 35°C to make the sodium-containing compound Na 2 SeO 3 Dissolves in liquid Ga, preferably, making the mixture com...

Embodiment 2

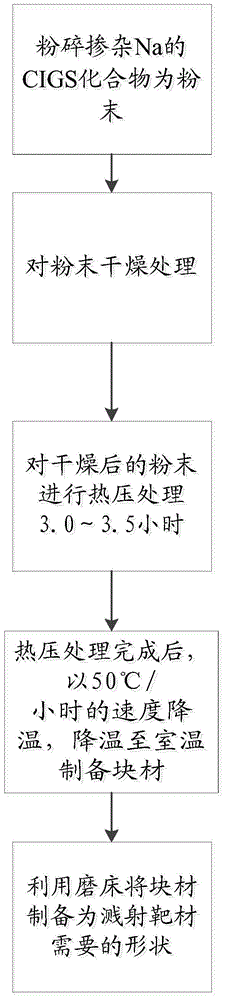

[0048] This embodiment also provides a kind of doped 1at%Na prepared by using embodiment 1 2 SeO 3 CuIn 0.7 Ga 0.3 Se 2 Compound material to make sputtering target method. By doping Na 2 SeO 3 The introduced Se atoms can fill the holes in the crystal lattice or other crystal defects, such as dislocations or grain boundaries, in the crystal grains of CIGS, thereby reducing the loss of carriers during the photoelectric conversion process.

[0049] First, dope with 1at% Na 2 SeO 3 CuIn 0.7 Ga 0.3 Se 2 The compound is placed in a closed device filled with an inert gas, such as argon, and the closed device is placed on a planetary ball mill for pulverization to prepare a powder material with an average particle size of 75 μm. Preferably, the powder is sieved to make the particle size of the powder more uniform.

[0050] Secondly, the powder prepared above is dried to remove moisture adsorbed on the surface of the powder. Specifically, the powder can be baked in an oven...

Embodiment 3

[0056] The present embodiment provides a kind of Na doping method of CIGS, it comprises the following steps:

[0057] Step 1, preparing a Na-containing solid solution of Ga.

[0058] First, according to the weight ratio Ga 96.3%, Na 2 S 3.7% weigh Ga and Na 2 S then places Ga in the quartz tube, where Ga and Na 2 The purity of S is above 99.99%. Secondly, the Ga in the quartz tube is heated to liquefy, and then the Na 2 Add S powder into the container to make Ga liquid and Na 2 S mixed. Finally, heat the mixture in the container to above 35°C to make the sodium-containing compound Na 2 S is dissolved in liquid Ga; then cooled naturally, so that the temperature of the mixture in the container is below 20°C, and the liquid is cooled and solidified into a solid, thereby obtaining a Ga-containing Na-containing solid solution.

[0059] Step 2, mixing the obtained Ga-containing Na-containing solid solution with copper, indium and selenium according to the required ratios of C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com