Manufacturing method of liquid-propellant rocket engine combustion chamber

A technology of liquid rockets and manufacturing methods, applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low welding strength, high cost, complicated process, etc., and achieve high processing efficiency, good reliability, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

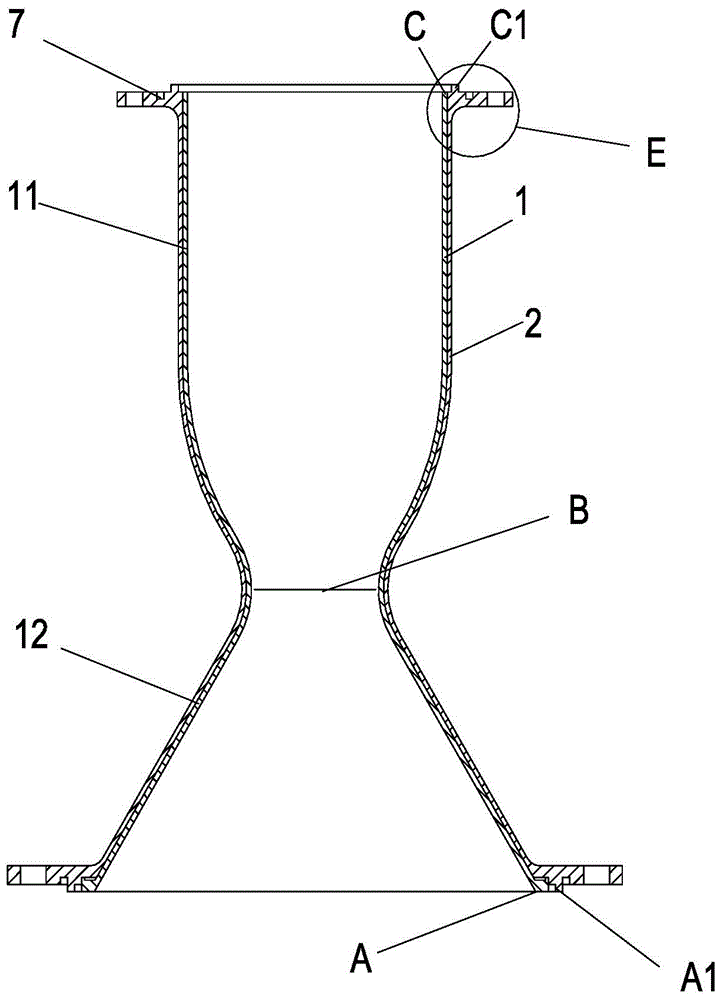

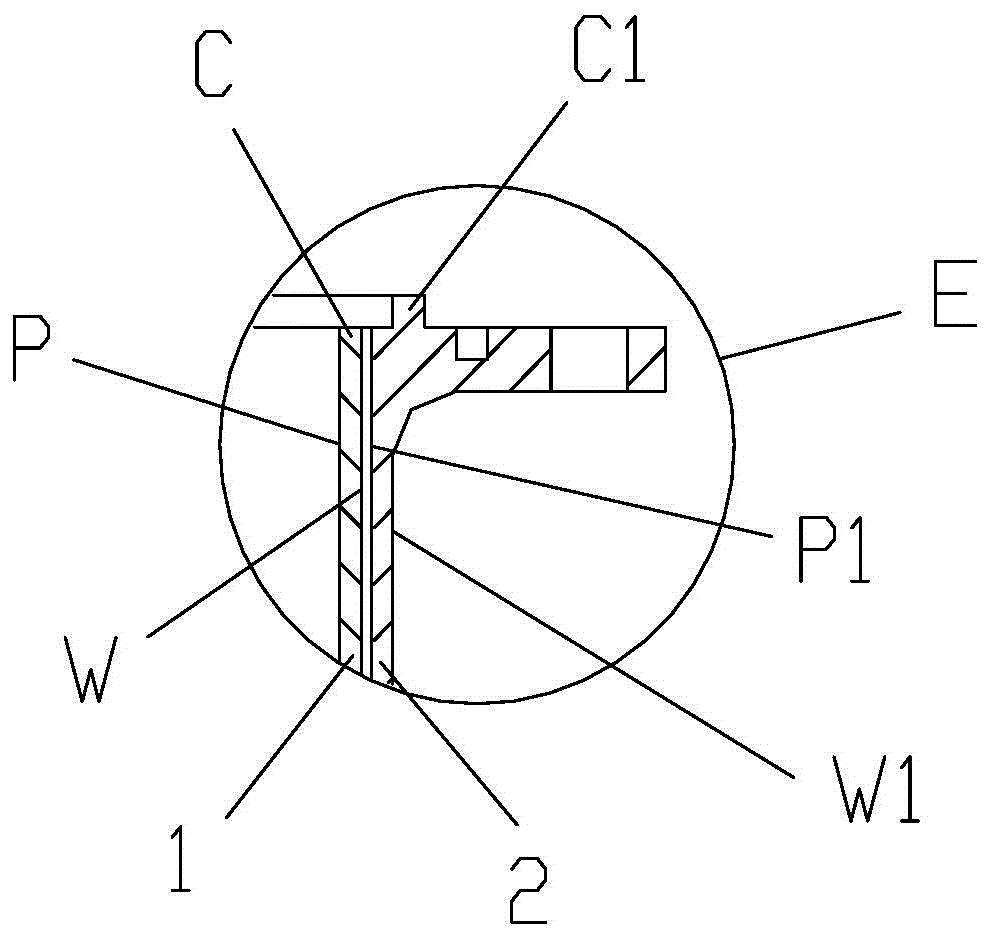

[0026] The structure of the combustor of a certain type of liquid rocket engine is as follows: figure 1 and figure 2 Shown in an hourglass shape, it is a copper alloy inner wall and a stainless steel outer wall. The largest diameter of the shape is connected to the injector port. The diameter d is 460mm, and the length H is 560mm. The manufacturing method of the combustion chamber includes the following steps:

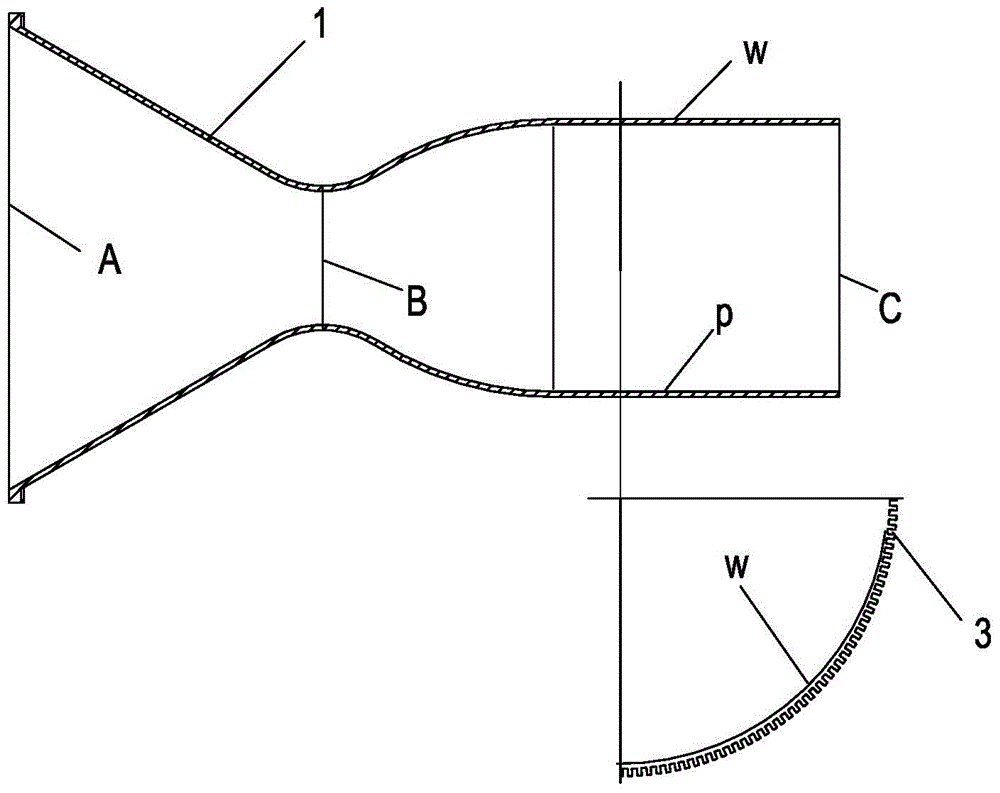

[0027] 1) For the inner wall 1, the structure is as image 3 As shown, the front sealing end surface A of the inner wall connected to one end of the injector and the rear sealing end surface C of the inner wall connected to the end of the tail nozzle, and the shape of the inner wall between the front sealing end surface A of the inner wall and the rear sealing end surface C of the inner wall The surface W is subjected to finishing treatment, and the liquid fuel self-circulation cooling channel 3 is arranged on the outer surface W of the inner wall;

[0028] 2) On th...

Embodiment 2

[0039] For a certain type of liquid rocket engine combustion chamber, its structure is as follows figure 1 and figure 2 Shown in an hourglass shape, it is a copper alloy inner wall and a stainless steel outer wall. The largest diameter of the shape is connected to the injector port. The diameter d is 660mm, and the length H is 560mm. The manufacturing method of the combustion chamber includes the following steps:

[0040] 1) For the inner wall 1, the structure is as image 3As shown, the front sealing end surface A of the inner wall connected to one end of the injector and the rear sealing end surface C of the inner wall connected to the end of the tail nozzle, and the shape of the inner wall between the front sealing end surface A of the inner wall and the rear sealing end surface C of the inner wall The surface W is subjected to finishing treatment, and the liquid fuel self-circulation cooling channel 3 is arranged on the outer surface W of the inner wall;

[0041] 2) On ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com