An alkaline zinc-manganese battery with improved high-power/current pulse discharge performance

A zinc-manganese battery and current pulse technology, which is applied to the electrodes of primary batteries and dry batteries, can solve the problems of large polarization, low battery capacity, short service life and unsuitable for development, and achieve easy preparation methods and materials. The effect of easy availability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Methods for preparing supercapacitor electrodes are known to those skilled in the art. Preferably, the current collector is coated with an electrode active material and wound.

[0060] More preferably, the supercapacitor electrode uses electrode active materials with a specific capacity of 10F / g-2000F / g and a power density of 10W / Kg-200KW / Kg.

[0061] The active material, a combination of one or more of carbon materials, metal oxides or conductive polymers:

[0062] (1) High specific surface area carbon material, said carbon material is preferably selected from activated carbon, ordered mesoporous carbon, carbide derived carbon, graphene, carbon aerogel, carbon fiber, carbon nanotube and onion carbon;

[0063] (2) Metal oxides, said metal oxides are preferably selected from RuO2, NiO, MnO2, Mn2O3, IrO, CoO, Co3O4, MoO, TiO2, V2O5, SnO2, Cr2O3, Fe3O4, Fe2O3, FeO;

[0064] (3) conductive polymer, the conductive polymer is preferably selected from polyaniline, polypropyl...

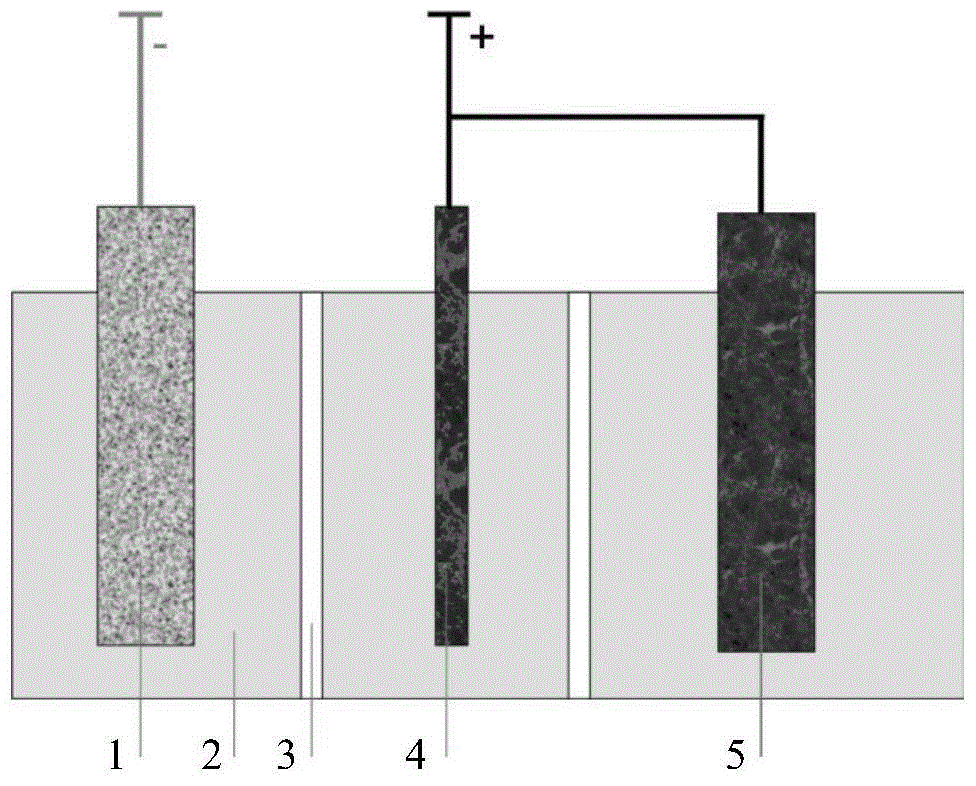

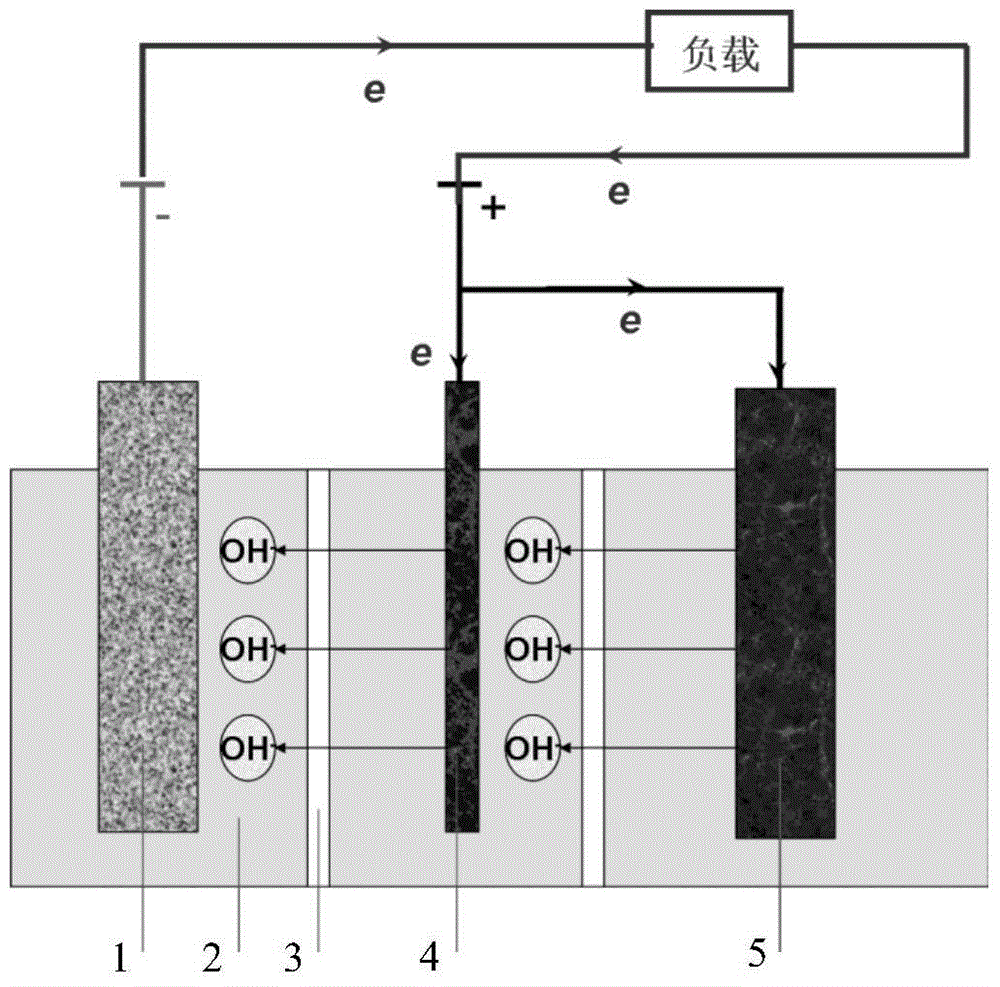

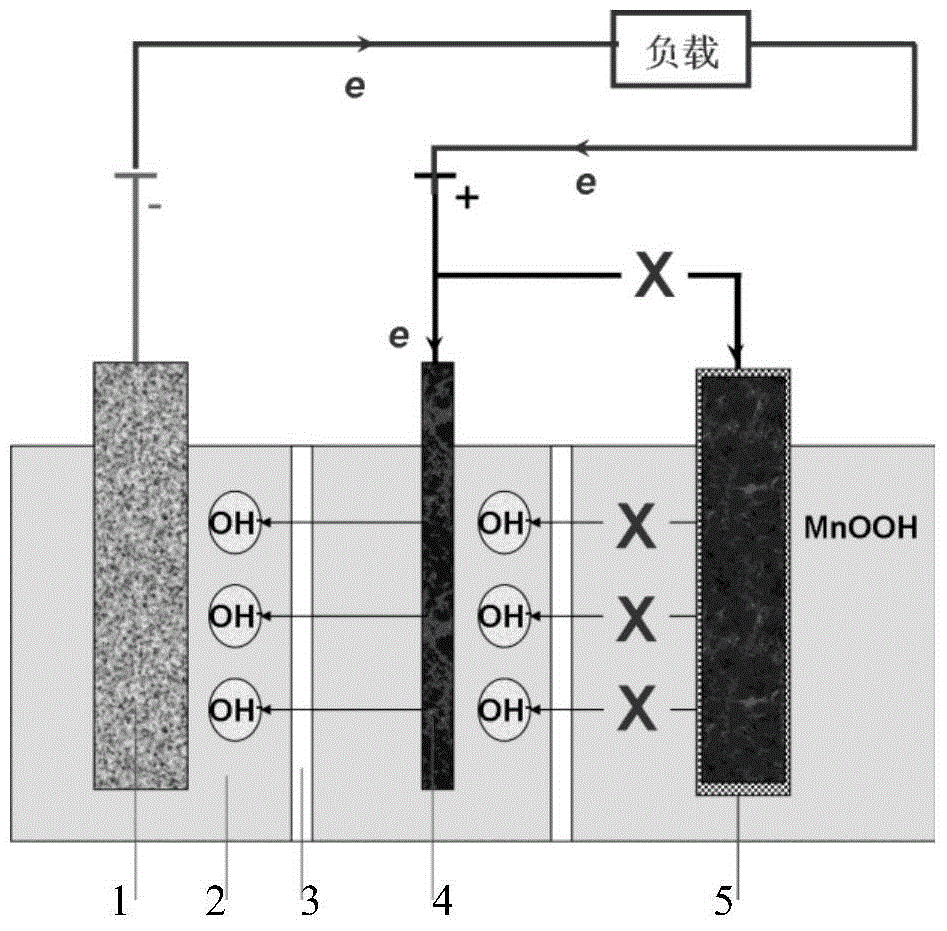

Embodiment 1

[0103] (1) The carbon material activated carbon (specific surface area is 2000m2 / g) is used as the supercapacitor active material, mixed with the conductive agent acetylene black and PVDF binder, and then coated on the current collector foam Ni to obtain a supercapacitor electrode (total weight 0.6 g, active carbon content 83%); (2) electrolytic manganese dioxide, graphite, zinc stearate, 40% KOH solution, after weighing, dry mixing, wet mixing, tableting, granulation, sieving, forming Obtain MnO at last anode ring (gross weight 10.35g, MnO content 88.14%, purity 92%); (3) positive electrode ring is embedded in steel case, then insert diaphragm paper and supercapacitor electrode, steel case and supercapacitor electrode are connected with wire (4) Insert the separator paper in turn, inject zinc paste, insert the current collector composed of copper nails, negative electrode bottom and sealing ring, crimp and shape the seal to obtain a high-power pulse discharge LR6 battery, and ...

Embodiment 2

[0105] (1) The carbon material graphene (the specific surface area is 200m2 / g) is used as the supercapacitor active material, mixed with the conductive agent acetylene black and PVDF binder, and then coated on the current collector stainless steel mesh to obtain the supercapacitor electrode (total weight 0.1 g, graphene content 95%); (2) electrolytic manganese dioxide, graphite, zinc stearate, 40% KOH solution, through weighing, dry mixing, wet mixing, tabletting, granulation, sieving, Obtain MnO2 positive electrode ring (gross weight 10.35g, MnO2 content 88.14%, purity 92%) after molding; (3) positive electrode ring is embedded in the steel shell, then insert diaphragm paper and supercapacitor electrode, steel shell and supercapacitor electrode are used wire Connection; (4) Insert the diaphragm paper in sequence, inject zinc paste, insert the current collector composed of copper nails, negative electrode bottom and sealing ring, crimp and shape the seal to obtain a high-power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com