Reverse-polarity AlGaInP light-emitting diode structure with window layer being covered with indium tin oxide

A technology of light-emitting diodes and indium tin oxide, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of inability to improve current expansion, inability to achieve ohmic contact, and increase the light output area of the window layer, so as to improve light extraction efficiency, The effect of improving current expansion capability and significant cost-effective advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

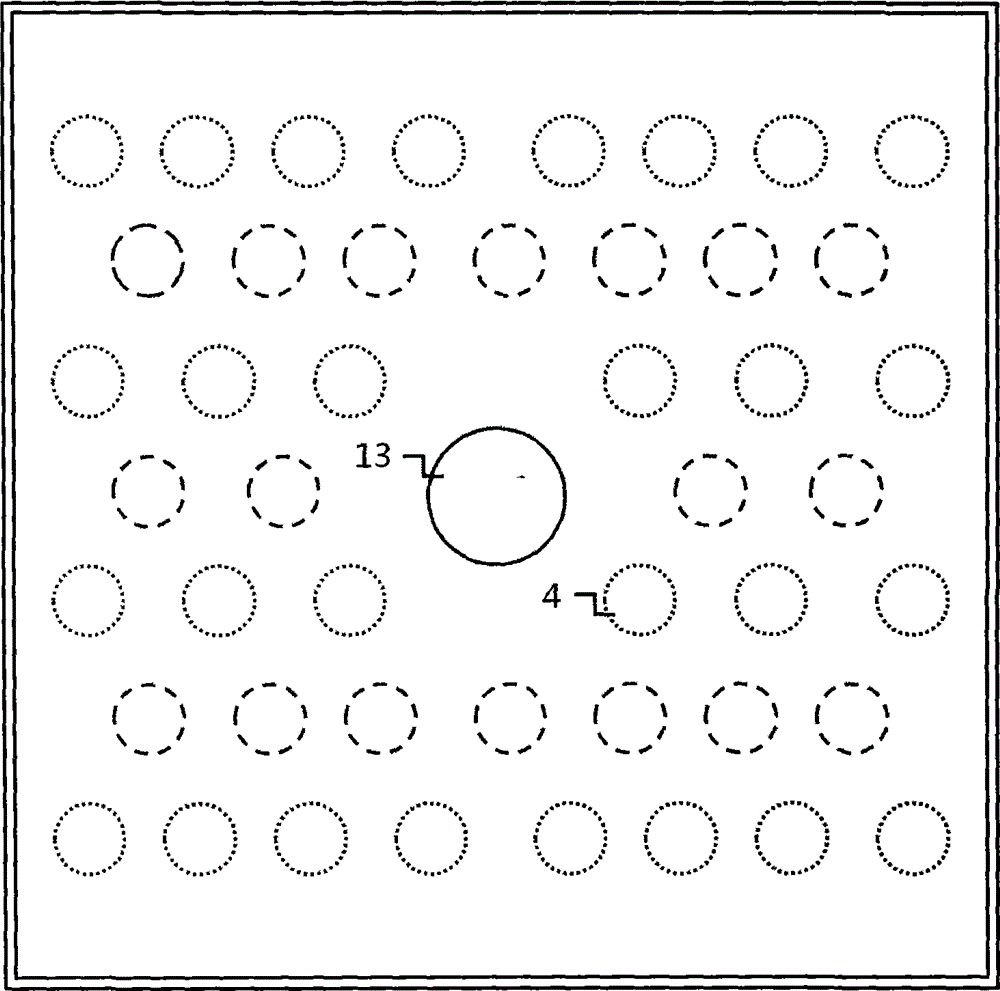

[0042] A reverse-polarity AlGaInP light-emitting diode structure with a window layer covered with indium tin oxide, the structure from bottom to top is p-electrode 1, substrate 2, bonding layer 3, mirror layer 4, insulating layer 5, current spreading Layer 6, p-type semiconductor layer 7, active region 8, n-type semiconductor layer 9, n-type semiconductor contact layer 10, window layer 11, indium tin oxide layer 12, n electrode 13; the indium tin oxide layer 12 covers The window layer 11 above the window layer 11 and penetrating the hole in the form of a cylinder is in direct contact with the n-type semiconductor contact layer 10 .

[0043] The p-electrode 1 is prepared on the back of the substrate 2, using a combination of Au and Ti materials, and prepared by evaporation, with a thickness of 0.5 μm;

[0044] The substrate 2 is made of Si material with a thickness of 20 μm;

[0045] The bonding layer 3 is made of Au material and prepared by evaporation, with a thickness of 0....

Embodiment 2

[0057] A kind of reverse polarity AlGaInP light-emitting diode structure that the window layer is covered with indium tin oxide as described in embodiment 1, and its difference is,

[0058] The p-electrode 1 is prepared on the back of the substrate 2, using a combination of Al and Ti materials, and prepared by evaporation, with a thickness of 1 μm;

[0059] The substrate 2 is made of Cu material with a thickness of 50 μm;

[0060] The bonding layer 3 is made of a combination of Au and In materials, prepared by evaporation, and has a thickness of 1 μm;

[0061] The reflector layer 4 is made of a combination of Ag, Ni, and Al materials, prepared by sputtering, and has a thickness of 0.5 μm;

[0062] Described insulating layer 5 selects TiO for use 2 The material is prepared by CVD with a thickness of 0.2 μm;

[0063] The current spreading layer 6 is a p-GaInP material prepared by MOCVD technology, and the p-type doping concentration is 1×10 19 cm -3 , with a thickness of 1 ...

Embodiment 3

[0072] A kind of reverse polarity AlGaInP light-emitting diode structure that the window layer is covered with indium tin oxide as described in embodiment 1, and its difference is,

[0073] The p-electrode 1 is prepared on the back of the substrate 2, using a combination of Ag, Ni, and Pt materials, and prepared by sputtering, with a thickness of 1 μm;

[0074] The substrate 2 is made of GaAs material with a thickness of 100 μm;

[0075] The bonding layer 3 is made of a combination of Al and Sn materials, prepared by evaporation, and has a thickness of 1.5 μm;

[0076] The reflector layer 4 is made of a combination of Au and Cr materials, prepared by sputtering, with a thickness of 1 μm;

[0077] The insulating layer 5 is made of Si 3 N 4 The material is prepared by CVD with a thickness of 0.5 μm;

[0078] The current spreading layer 6 is a p-GaAs material prepared by MOCVD technology, and the p-type doping concentration is 1×10 20 cm -3 , with a thickness of 2 μm;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com