Colored photosensitive resin composition for color filter, color filter and liquid crystal display device having the same

A technology of photosensitive resin and composition, which is applied in the direction of photosensitive materials, optical filters, and optomechanical equipment used in optomechanical equipment to achieve the effects of excellent brightness, fast development speed and less color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

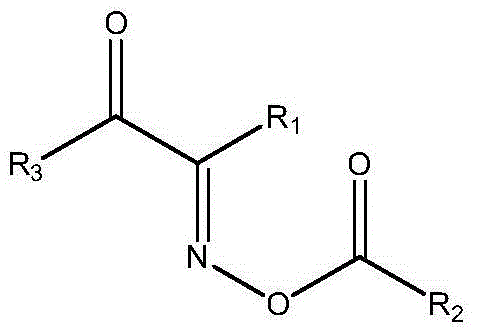

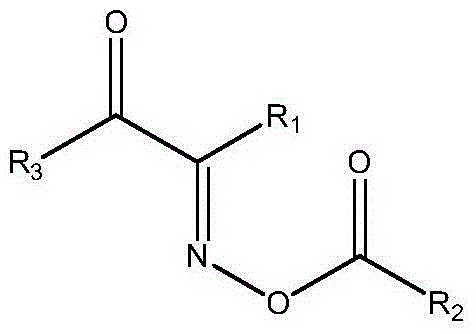

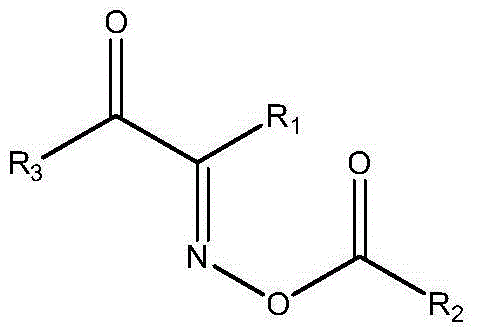

Image

Examples

experiment example

[0145] Manufacture of Pigment Dispersion Compositions

[0146]

[0147] 10.85 parts by weight of C.I. Pigment Red 254, 3.80 parts by weight of AJISPUR PB821 (manufactured by Ajinomoto FineTechno Co., Ltd.) as a dispersant, 76.90 parts by weight of propylene glycol monomethyl ether acetate as a solvent, and 8.45 parts by weight of The cyclohexanone was mixed and dispersed for 12 hours, thereby producing the pigment dispersion liquid M1.

[0148] Synthesis of Alkali Soluble Resin

Synthetic example 1

[0150] 120 parts by weight of propylene glycol monomethyl ether acetate, 80 parts by weight of propylene glycol monomethyl ether, 2 parts by weight of azobisiso Butyronitrile (AIBN), 13.0 parts by weight of acrylic acid, 10 parts by weight of benzyl methacrylate, 57.0 parts by weight of 4-methylstyrene, 20 parts by weight of methyl methacrylate, 3 parts by weight of n-dodecyl Alkylthiols with nitrogen replacement. After that, stirring was performed, and the temperature of the reaction liquid was raised to 110° C., and the reaction was performed for 6 hours. The solid content of the alkali-soluble resin thus synthesized had an acid value of 100.2 mgKOH / g, and a weight average molecular weight Mw measured by gel permeation chromatography (GPC) was about 15,110.

[0151] Manufacture of colored photosensitive resin composition

Embodiment 1

[0153] Mix the above-mentioned of 36.50 weight parts, the acid red (Acid Red 52, TCI America company) of 0.54 weight parts, the resin of of 10.11 weight parts, the KAYARAD DPHA of 3.86 weight parts (Japan Kayaku Corporation), 1.00 parts by weight of TR-PBG-305 (manufactured by TRONLY Corporation), 0.23 parts by weight of 1,3,5-trimethyl-2,4,6-tris(3 ,5-di-tert-butyl-4-hydroxybenzyl)benzene (1,3,5-Trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene) (240 hours, Aldrich Company), 0.15 parts by weight of triphenyl phosphate (Triphenyl phosphate) (Aldrich Company), 12.75 parts by weight of 4-hydroxyl-4-methyl-2-pentanone , 34.85 parts by weight of propylene glycol monomethyl ether acetate to manufacture a colored photosensitive resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com