Well completion method with shale gas layer radial jetting drilling and volume fracturing combined

A technology of jet drilling and volume fracturing, which is applied in liquid/gas jet drilling, directional drilling, wellbore/well components, etc. It can solve operational risks and cost increases, poor acid fracturing effects, and difficulty in flowback, etc. to reduce the cost and risk of single well operation, increase the extension length of fractures, and facilitate flowback after fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

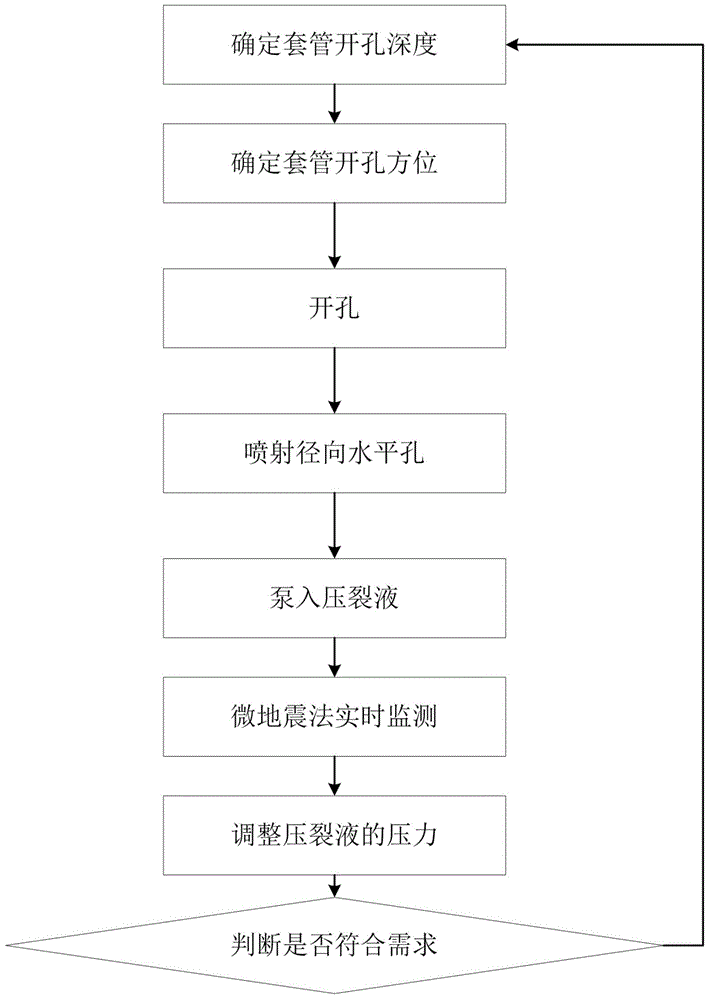

[0036] Such as figure 1 Shown is a flow chart of a shale gas layer radial jet drilling combined with volume fracturing completion method provided by the present invention. The specific steps include: using magnetic positioning and natural gamma ray logging to determine the opening of the casing Depth; use gyro inclinometer to determine casing drilling orientation; use drill tool assembly including milling bit to drill holes in the casing of the target layer; inject radial horizontal holes in the target layer through coiled tubing injection assembly ;Pump fracturing fluid into the ejected radial horizontal holes through coiled tubing and injection components to obtain rock fractures; use microseismic monitoring method to monitor the scale and extension direction of rock fractures in real time to obtain the scale and extension of rock fractures Direction data; adjust the parameters of pumped fracturing fluid in real time according to the scale and extension direction data of roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com