Clean process for comprehensively recovering diamond and various metal resources from waste diamond tools

A diamond tool and diamond technology, applied in the field of cleaning technology, can solve problems such as poor environment, low recovery rate, and low comprehensive utilization rate, and achieve the effects of cost reduction, efficient recovery, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

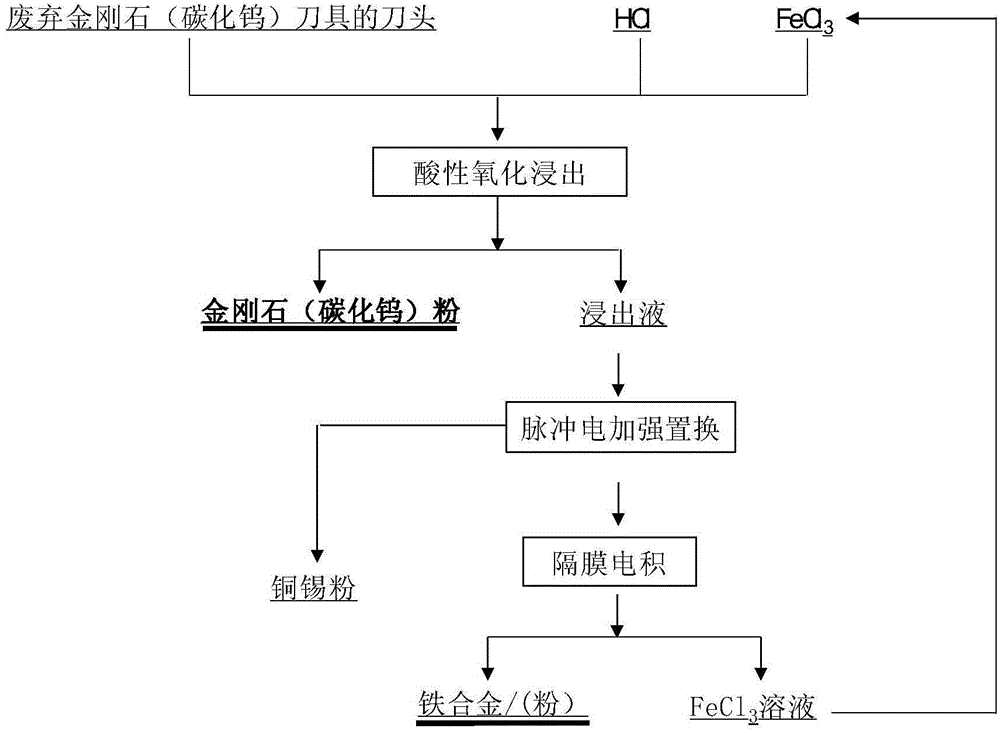

Method used

Image

Examples

Embodiment 1

[0039] The composition of the waste diamond segment provided by a company in Yunnan is: Fe 82.5%, Cu 9.2%, Sn 2.1%, Ni 1.8%, C 2%.

[0040] Get above-mentioned discarded diamond cutter head 100g, in containing FeCl 3 -Dissolve in the HCl system, the dissolution temperature is controlled at 40°C, and the pH value of the solution at the end of the dissolution is controlled at 2, Fe 3+ / (Fe 2+ +Fe 3+ ) = 0.08. Afterwards, separate by filtration, combine the washing liquid and the filtrate, dry and weigh the filter residue. The iron, copper, tin and nickel contents in the filtrate and filter residue were analyzed, and the leaching rates of iron, copper, tin and nickel were all above 99.6%, and the diamond powder yield was close to 100%.

[0041] The leaching solution is reduced by pulse electric enhanced replacement, the pulse frequency of the pulse electric field is 500Hz, the duty cycle is 50%, and the pulse average current density is 200A / m. 2 ; The replacement temperature...

Embodiment 2

[0044] The composition of discarded tungsten carbide cutter heads provided by a company in Hunan is: Fe 75.5%, Cu 13.4%, Sn 4.6%, Ni 2.1%, WC 3.7%.

[0045] Get above-mentioned discarded tungsten carbide cutter head 500g, in containing FeCl 3 -Dissolve in the HCl system, the dissolution temperature is controlled at 30°C, and the pH value of the solution at the end of the dissolution is controlled at 1, Fe 3+ / (Fe 2+ +Fe 3+ ) = 0.1. Afterwards, separate by filtration, combine the washing liquid and the filtrate, dry and weigh the filter residue. The iron, copper, tin and nickel contents in the filtrate and filter residue were analyzed, and the leaching rates of iron, copper, tin and nickel were all above 99%, and the yield of tungsten carbide powder was close to 100%.

[0046] The leaching solution is reduced by pulse electric enhanced displacement. When pulse electric enhanced displacement, the pulse frequency of the pulse electric field is 1000Hz, the duty cycle is 70%, a...

Embodiment 3

[0049] The composition of the waste diamond and tungsten carbide cutter head mixture provided by a company in Hunan is: Fe 79.0%, Cu 10.4%, Sn 4.6%, Ni 2.1%, WC 1.8%, C 2.1%.

[0050] Get above-mentioned discarded diamond and tungsten carbide mixed cutter head 2500g, in FeCl-containing 3 -Dissolve in the HCl system, the dissolution temperature is controlled at 60°C, and the pH value of the solution at the end of the dissolution is controlled at 2, Fe 3+ / (Fe 2+ +Fe 3+ ) = 0.09. Afterwards, separate by filtration, combine the washing liquid and the filtrate, dry and weigh the filter residue. Analysis of the iron, copper, tin and nickel contents in the filtrate and filter residue shows that the leaching rates of iron, copper, tin and nickel are all above 97.5%, and the yields of tungsten carbide powder and diamond powder are close to 100%.

[0051] The leaching solution is reduced by pulse electric enhanced displacement. When the pulse electric enhanced displacement is perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com