Method for rapidly preparing high-performance Si3N4 ceramic ball at low cost

A ceramic ball and high-performance technology, applied in the field of preparing high-performance Si3N4 ceramic balls, can solve the problems of long nitriding time, harsh densification conditions, and difficult densification of Si powder, achieve uniform distribution, improve densification and performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

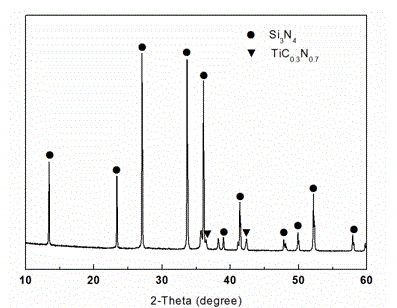

Image

Examples

Embodiment 1

[0031] The preparation of high-performance Si provided by the present invention 3 N 4 The method of ceramic ball, comprises the steps:

[0032] (1) Using Si powder as raw material, TiO 2 -Al 2 o 3 -Re 2 o 3 As an auxiliary agent, where Re=Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu any one, according to Si: TiO 2 :Al 2 o 3 :Re 2 o 3 The mass fraction ratio is 56-99.44%: 0.22-17.44%: 0.17-13.3%: 0.17-13.3%. After mixing and drying, Si-TiO 2 -Al 2 o 3 -Re 2 o 3 mixed powder;

[0033] (2) Si-TiO mixed uniformly 2 -Al 2 o 3 -Re 2 o 3 The powder is granulated by a spray drying process, and then the granulated powder is put into a mold for ceramic ball molding, and finally a ceramic ball green body with a certain density and strength is obtained by a cold isostatic pressing process;

[0034] (3) Si-TiO 2 -Al 2 o 3 -Re 2 o 3 The ceramic ball green body adopts a two-step heat preservation method and uses air pressure sintering to prepare...

Embodiment 2

[0042] In the present embodiment, Re=Y, specific preparation high-performance Si 3 N 4 The ceramic ball method is as follows:

[0043] According to the Si powder mass fraction of 83.61%, TiO 2 Powder mass fraction is 4.02%, Al 2 o 3 Mass fraction is 3.09%, Y 2 o 3 The powder mass fraction is 9.28% to carry out batching, prepare Si according to the method of embodiment 1 3 N 4 ceramic balls. The relative density of the prepared ceramic material is greater than 99%, the hardness of the material is 18GPa, and the fracture toughness is 8MPa·m 1 / 2 , The bending strength is 1100Mpa.

Embodiment 3

[0045] In this embodiment, Re=Lu, specific preparation of high-performance Si 3 N 4 The ceramic ball method is as follows:

[0046] According to Si powder mass fraction of 85.1%, TiO 2 Powder mass fraction is 4.5%, Al 2 o 3 Mass fraction is 5.5%, Lu 2 o 3 Powder mass fraction is 4.9% and carries out batching, prepares Si according to the method for embodiment 1 3 N 4 ceramics. The relative density of the prepared ceramic material is higher than 99%, the hardness of the material is 18.5GPa, and the fracture toughness is 8.5MPa·m 1 / 2 , The bending strength is 1000Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com