Reed-type environment-friendly coated silver brazing filler metal ring

A kind of silver brazing material, environment-friendly technology, applied in the field of spring-shaped environment-friendly coating silver brazing material ring, can solve the problems that cannot be used to produce non-bar or rod coating solder, damage the health of operators, pollute the environment, etc. , to achieve the effects of shortening melting time, low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

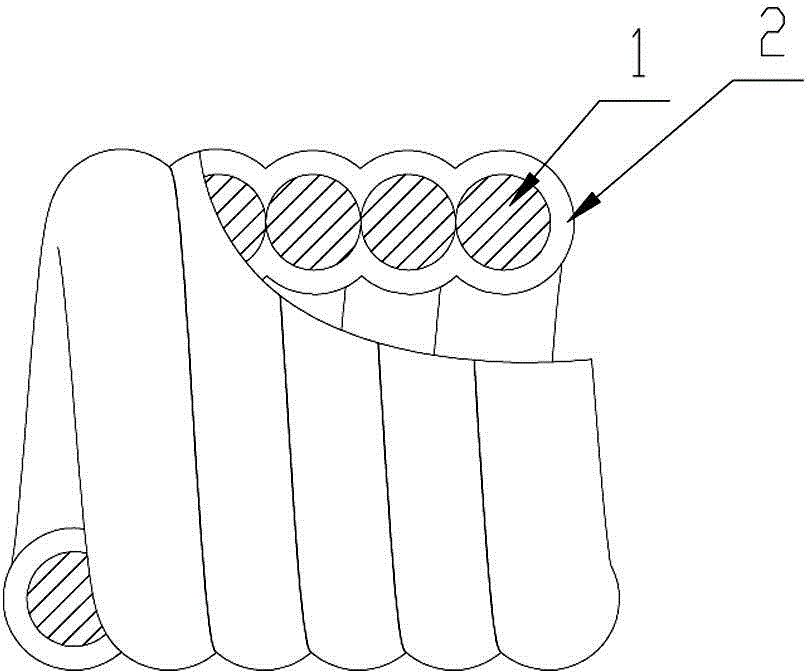

Image

Examples

Embodiment 1

[0017] The preparation method of the spring-shaped environment-friendly type drug-coated silver solder ring of the present invention is as follows:

[0018] a) Mix silver, copper, zinc, and tin according to the ratio of 34:36:27.5:2.5 and melt them, cast them into Φ50 mm rod-shaped solder alloy ingots, cut off the risers and turn the ingots to remove scale ,stand-by;

[0019] b) Raise the temperature of the solder extrusion equipment to 460 °C, place the turned ingot in the muffle furnace for preheating, the preheating temperature is 470 °C, put the preheated ingot into the mold of the extrusion equipment Inside, extruded into a Φ1.7 mm solder wire, and drawn to a Φ0.7 mm silver solder wire;

[0020] c) Clean the drawn silver brazing wire and put it into the material tray of the ring-making equipment, and wind the silver brazing wire into a hollow structure with a middle diameter of Φ4.5 mm and a number of turns of 4 turns. A spring-shaped solder core with a distance (the ax...

Embodiment 2

[0025] The preparation method of the spring-shaped environment-friendly type drug-coated silver solder ring of the present invention is as follows:

[0026] a) Mix silver, copper, zinc, nickel and manganese according to the ratio of 49:16:23:4.5:7.5 and melt them, cast them into Φ50 mm rod-shaped solder alloy ingots, cut off the risers and then cast the ingots Turning to remove scale, set aside;

[0027] b) Raise the temperature of the solder extrusion equipment to 460 °C, place the turned ingot in the muffle furnace for preheating, the preheating temperature is 470 °C, put the preheated ingot into the mold of the extrusion equipment Inside, extruded into Φ2.5 mm solder wire, and drawn to Φ1.0 mm silver solder wire;

[0028] c) Clean the drawn silver brazing wire and put it into the material tray of the ring-making equipment, wind the silver brazing wire into a hollow structure with a middle diameter of Φ8.0mm, the number of turns is 2 turns, and the pitch (The axial distanc...

Embodiment 3

[0033] The preparation steps are the same as in Example 1, and the difference is that the solder composition is silver: copper: zinc=45:30:25; the preheated ingot is put into the die barrel of the extrusion equipment and extruded into Φ2. 0 mm brazing wire, and rolled into oblate silver brazing material with a thickness of 0.9 mm; Silver flux containing 20% sodium fluoride, 35% potassium fluoroborate, 42% boric acid, and 3% elemental boron is placed in a container and water is added to make a viscous saturated flux liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Middle diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Middle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com