Pancreatin enteric coating pellet and preparation method therefor

A technology of enteric-coated pellets and pancreatic enzyme pellets, which is applied in the fields of pharmaceutical formulations, medical preparations containing active ingredients, and the digestive system, can solve the problems of poor stability and large particles of pancreatic lipase, and achieve a simple and easy preparation method OK, high safety factor, reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

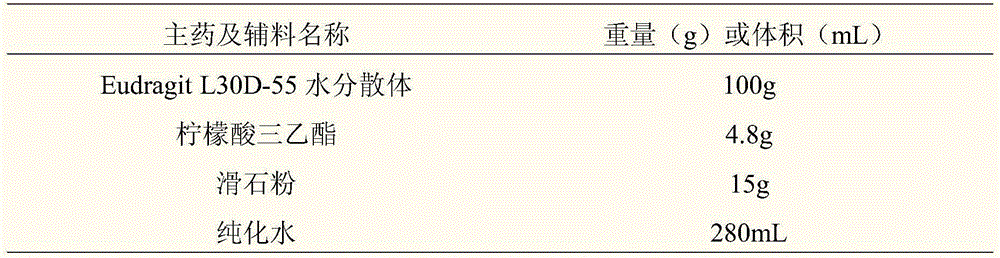

[0050] The present invention also provides a preparation method of pancreatin enteric-coated pellets, including the preparation of pancreatin enteric-coated pellets, the preparation of enteric liquid and the preparation of pancreatin enteric-coated pellets, specifically comprising the following steps:

[0051] Step 1: Pass the formulated amount of active pancreatin powder, diluent, disintegrant, and binder through a 100-mesh sieve, mix well, and add an appropriate amount of water to make a moist, uniform and plastic soft material;

[0052] Step 2: put the soft material prepared in step 1 into an extruder, and extrude thin strips of equal diameter;

[0053] Step 3: Quickly add the equal-diameter strip-shaped extrudates prepared in step 2 into the spheronizer in batches, and set the parameters of the spheronizer so that the drug particles are rounded;

[0054] Step 4: Dry the spherical drug granules prepared in Step 3 at 37°C for 12-20 hours to obtain pancreatin pellets;

[005...

Embodiment 1

[0066] The preparation of embodiment 1 trypsin pellet

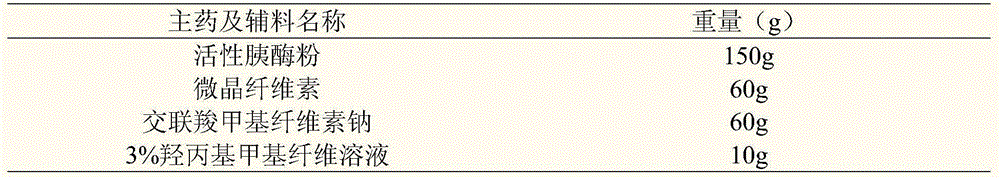

[0067] Table 1 Prescription of trypsin pellets

[0068]

[0069] The preparation method of trypsin pellet

[0070] 1. After mixing active pancreatin powder, microcrystalline cellulose and croscarmellose sodium evenly, use 3% hydroxypropyl methylcellulose solution to make it into a moist, uniform and plastic soft material.

[0071] 2. Put the above-mentioned soft material into an extruder, and extrude (with a sieve plate aperture of 1.0mm) a thin strip-like extrudate of equal diameter through the extruder.

[0072] 3. Quickly add the extruded product into the spheronizer in batches, adjust the parameters of the spheronizer to make the drug granules completely spheroidized and dry at 37°C for 20 hours, take out the pellets and granulate to obtain the product.

Embodiment 2

[0073] The preparation of embodiment 2 trypsin pellets

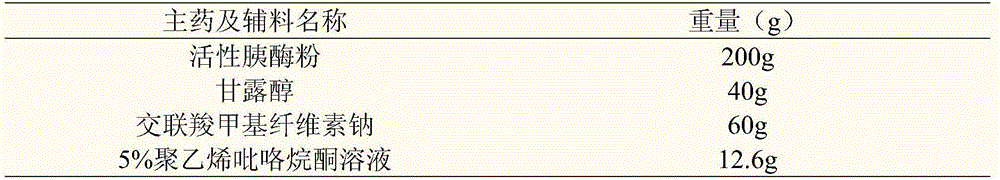

[0074] Table 2 Prescription of trypsin pellets

[0075]

[0076] The preparation method of trypsin pellet

[0077] 1. After mixing active pancreatin powder, mannitol and croscarmellose sodium evenly, use 5% polyvinylpyrrolidone solution to make it into a moist, uniform and plastic soft material.

[0078] 2. Put the above-mentioned soft material into an extruder, and extrude (with a sieve plate aperture of 1.0mm) a thin strip-like extrudate of equal diameter through the extruder.

[0079] 3. Quickly add the extruded product into the spheronizer in batches, adjust the parameters of the spheronizer to make the drug granules completely spheroidized and dry at 40°C for 15 hours, take out the pellets and granulate, and the product is ready.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com