Fuel combustion system with a perforated reaction holder

A stabilizer and reaction technology, applied to gas fuel burners, burning with multiple fuels, burners, etc., can solve problems such as long residence time, uneven heating of steam pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

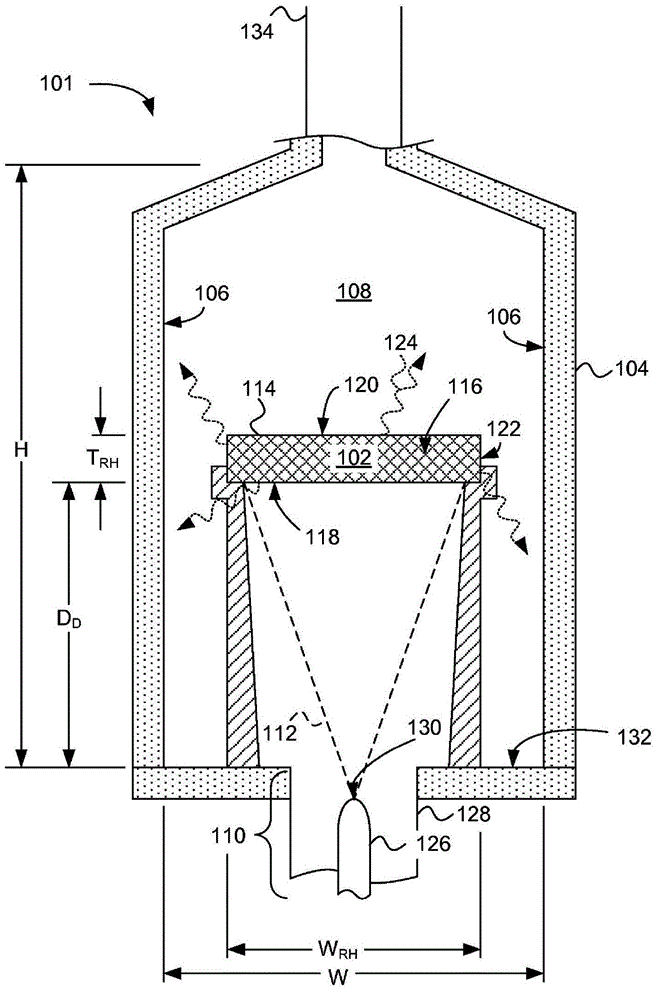

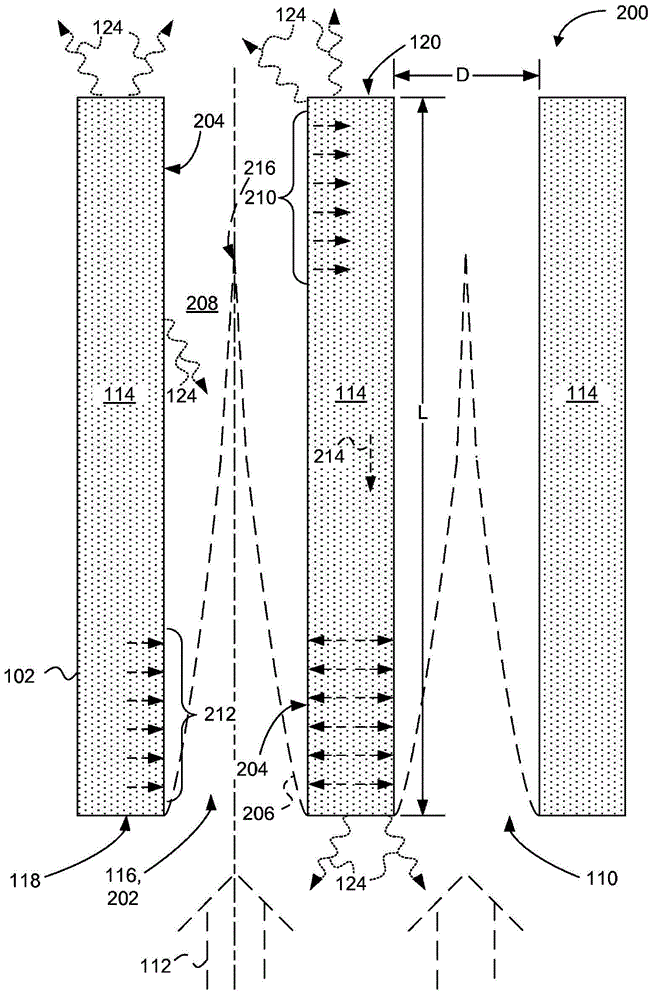

[0157] Figure 12 is a schematic diagram of an experimental setup 1200 used to determine the effect of dilution distance between a fuel nozzle and a perforated reaction stabilizer, according to one embodiment. In the experimental setup, the test ignition was carried out under the following conditions:

[0158] The fuel is methane.

[0159] Fuel pressure varies but is always around 12 psi.

[0160] The fuel nozzle (pinhole) diameter is 0.11".

[0161] The airlock in the exhaust stack was always "closed" with about 1 / 4" of clearance around the airlock. The stack size was about 12" square. The 1 / 4" gap allows the exhaust flue damper to never fully close.

[0162] The air source (inlet air) was natural draft and confined in a 3" hole positioned concentrically with the fuel nozzle tube occupying 1 / 4" around the center of the 3" hole.

[0163] 3% O in the stack 2 for NOx comparison.

[0164] The perforated reaction stabilizer had a total thickness of 4" (L dimension). The 4" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com