Silver-germanium-copper composite structural component and preparation method and use thereof

A composite structure and device technology, applied in the field of silver-germanium-copper composite structure devices and their preparation, can solve the problems of less species, energy loss of excitation light and outgoing signal, etc., and achieve convenient real-time monitoring, improved sensitivity, and high SERS activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The concrete steps of preparation are:

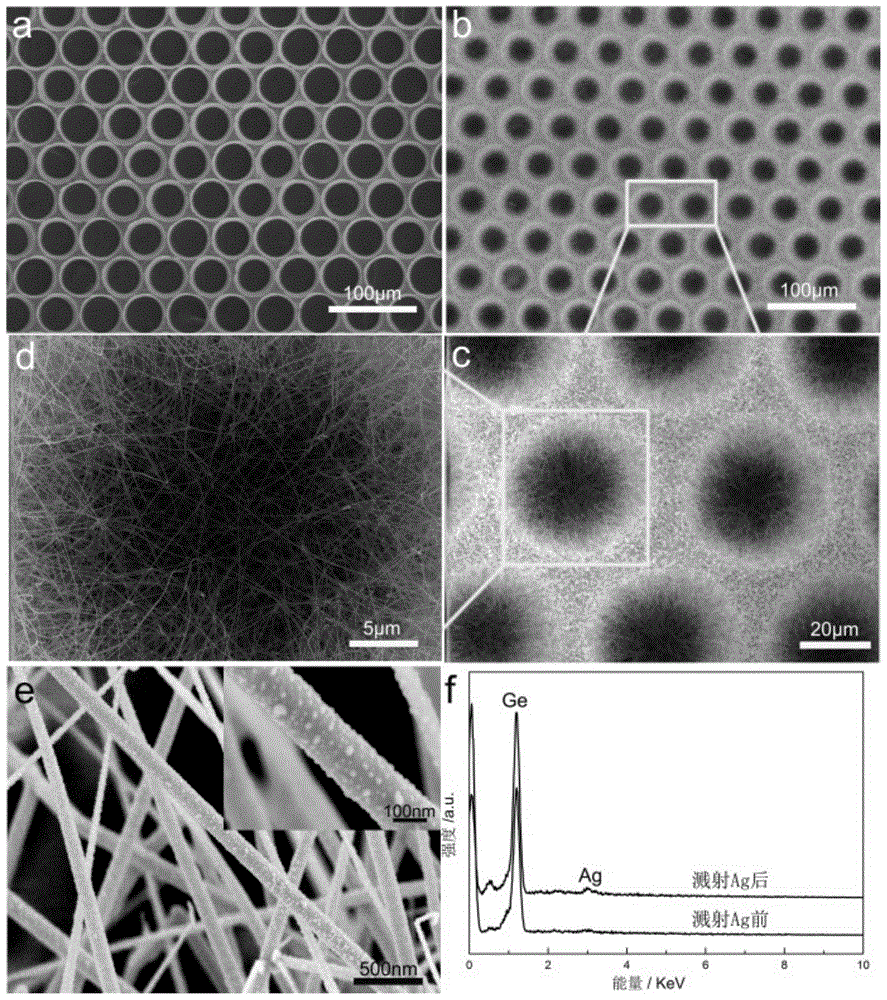

[0037] Step 1: Firstly, the copper mesh with a mesh diameter of 35 μm is ultrasonically cleaned with ethanol and deionized water, and then placed in a sputtering apparatus at a place 1.5 cm from the gold target, and sputtered at a sputtering current of 25 mA for 1.5 min. A copper mesh with gold nanoparticles vapor-deposited on its surface and mesh walls was obtained. Then place the copper mesh with gold nanoparticles vapor-deposited on its surface and mesh walls in a mixed atmosphere of germane and argon, and keep it warm at 310°C for 35min, wherein the mixed atmosphere of germane and argon has a flow rate of 3.5mL / min of germane and 60mL / min of argon mixed gas, to obtain approximately figure 1 b~ figure 1 A copper mesh with germanium nanowires is constructed on the surface and mesh walls shown in d.

[0038] Step 2, place the copper mesh with germanium nanowires on its surface and mesh walls at 1.5 cm from the silver target ...

Embodiment 2

[0040] The concrete steps of preparation are:

[0041] Step 1: First, after ultrasonically cleaning the copper mesh with a mesh diameter of 38 μm with ethanol and deionized water, place it at the gold target 1.8 cm in the sputtering apparatus, and sputter at a sputtering current of 23 mA for 1.8 min. A copper mesh with gold nanoparticles vapor-deposited on its surface and mesh walls was obtained. Then place the copper mesh with gold nanoparticles vapor-deposited on its surface and mesh walls in a mixed atmosphere of germane and argon, and keep it warm at 320°C for 34min, wherein the mixed atmosphere of germane and argon has a flow rate of 3.8mL / min of germane and 60mL / min of argon mixed gas, to obtain approximately figure 1 b~ figure 1 A copper mesh with germanium nanowires is constructed on the surface and mesh walls shown in d.

[0042] Step 2, place the copper mesh with germanium nanowires on its surface and mesh walls at the silver target 1.8cm in the sputtering appara...

Embodiment 3

[0044] The concrete steps of preparation are:

[0045] Step 1: First, after ultrasonically cleaning the copper mesh with a mesh diameter of 40 μm with ethanol and deionized water, place it at a place 2 cm away from the gold target in the sputtering apparatus, and sputter at a sputtering current of 20 mA for 2 minutes to obtain its Copper mesh with gold nanoparticles evaporated on the surface and the mesh walls. Then place the copper mesh with gold nanoparticles vapor-deposited on its surface and mesh walls in a mixed atmosphere of germane and argon, and keep it warm at 330°C for 33 minutes, wherein the mixed atmosphere of germane and argon has a flow rate of 4mL / min The mixed gas of germane and 60mL / min argon can be obtained as figure 1 b~ figure 1 A copper mesh with germanium nanowires is constructed on the surface and mesh walls shown in d.

[0046] Step 2, place the copper mesh with germanium nanowires on its surface and mesh walls at the silver target 2cm in the sputter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com