Preparation method of rod-like lithium disilicate crystal

A lithium disilicate and crystal technology is applied in the field of preparation of rod-shaped lithium disilicate crystals, which can solve the problems of affecting the light transmittance properties of lithium disilicate materials, unable to meet the matching of strength and toughness, etc., and achieve a controllable aspect ratio. , low cost, the effect of increasing the ion diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

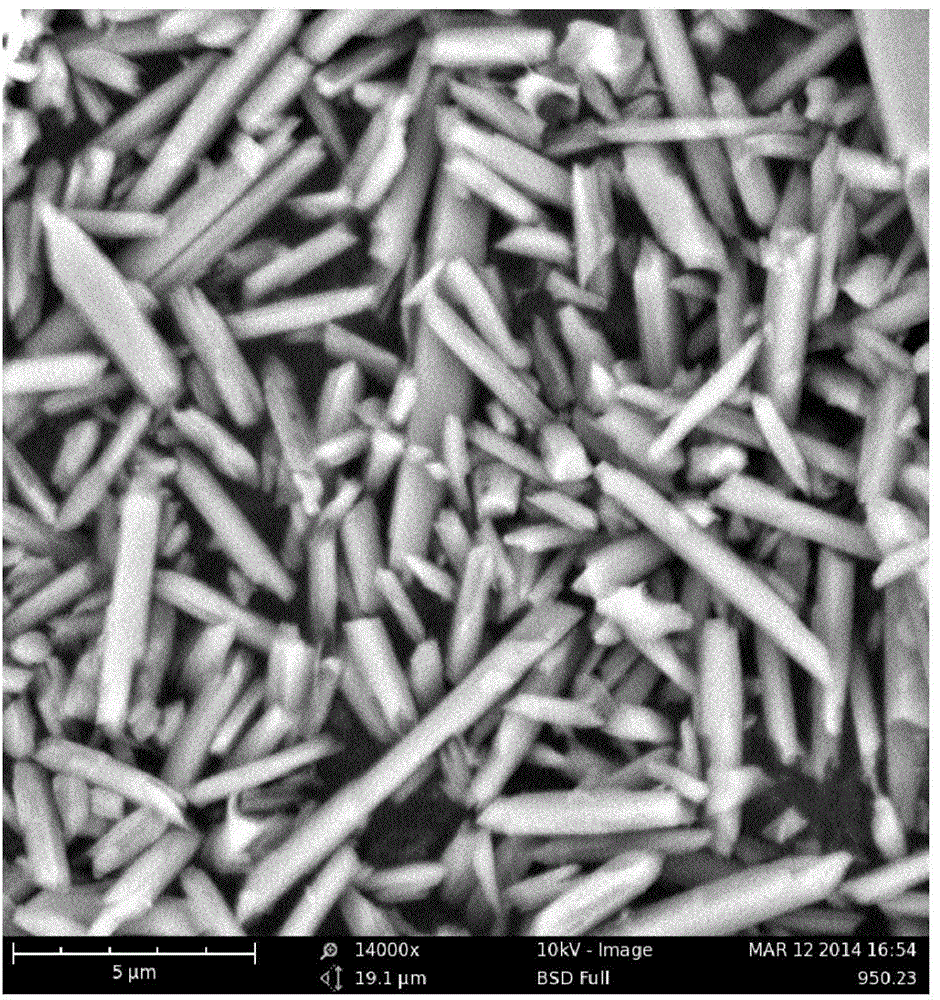

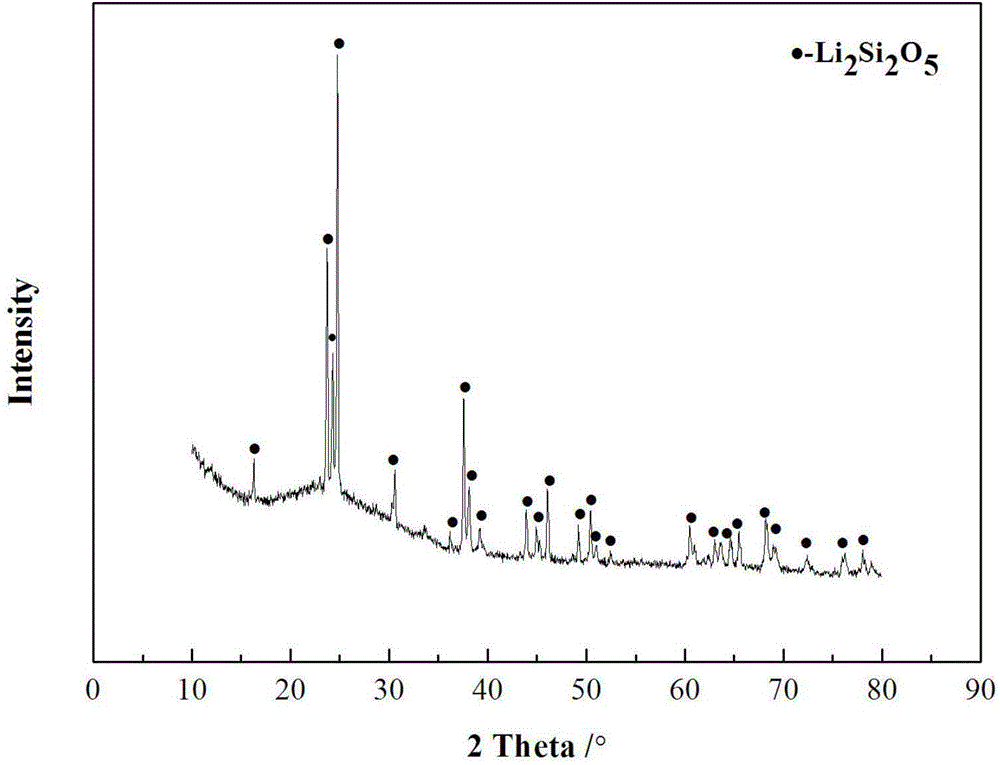

Embodiment 1

[0022] A method for preparing rod-shaped lithium disilicate crystals, comprising the following steps:

[0023] (1) Obtaining of raw material mixed powder: according to the molar ratio of SiO 2 / Li 2 CO 3 =1.5, carry out mass conversion: mass ratio SiO 2 / Li 2 CO 3 =1.216, take by weighing average particle diameter and be 5 μ m high-purity lithium carbonate powder (purity is 99.99%) 4.52g, nanometer high-purity silicon dioxide powder (purity is 99.99%) 5.48g, add dehydrated alcohol 40g, adopt oxidation Zirconium balls were wet-milled for 10 hours, mixed evenly, and then evaporated on a rotary evaporator to dry the alcohol, took it out, put it in a drying oven at 80°C, dried and sieved;

[0024] (2) Obtaining of raw powder of seed crystal: the raw material mixed powder after drying and sieving is mixed with adding flux to analyze pure Na 2 SO 4 Powder (purity ≥ 99%), by mass ratio: Na 2 SO 4 Powder / raw material mixed powder = 4 for weighing and mixing, adding 75g of abs...

Embodiment 2

[0029] A method for preparing rod-shaped lithium disilicate crystals, comprising the following steps:

[0030] (1) Obtaining of raw material mixed powder: according to the molar ratio of SiO 2 / Li 2 CO 3 =1.5, carry out mass conversion: mass ratio SiO 2 / Li 2 CO 3 =1.216, taking by weighing average particle diameter is 5 μ m high-purity lithium carbonate powder (purity is 99.99%) 9.04g, nanometer high-purity silicon dioxide powder (purity is 99.99%) 10.96g, adds dehydrated alcohol 80g, adopts oxidation Zirconium balls were wet-milled for 10 hours, mixed evenly, and then evaporated on a rotary evaporator to dry the alcohol, took it out, put it in a drying oven at 80°C, dried and sieved;

[0031] (2) Obtaining of raw powder of seed crystal: the raw material mixed powder after drying and sieving is mixed with adding flux to analyze pure Na 2 SO 4 Powder (purity ≥ 99%), by mass ratio: Na 2 SO 4 Powder / raw material mixed powder = 2 for weighing and mixing, adding 90g of ab...

Embodiment 3

[0036] A method for preparing rod-shaped lithium disilicate crystals, comprising the following steps:

[0037] (1) Obtaining of raw material mixed powder: according to the molar ratio of SiO 2 / Li 2 CO 3 =2, carry out mass conversion: mass ratio SiO 2 / Li 2 CO 3 =1.62, taking by weighing average particle diameter is 5 μm high-purity lithium carbonate powder (purity is 99.99%) 6.18g, nanometer high-purity silicon dioxide powder (purity is 99.99%) 3.82g, adds dehydrated alcohol 40g, adopts oxidation Zirconium balls were wet-milled for 10 hours, mixed evenly, and then evaporated on a rotary evaporator to dry the alcohol, took it out, put it in a drying oven at 80°C, dried and sieved;

[0038] (2) Obtaining of raw powder of seed crystal: the raw material mixed powder after drying and sieving is mixed with adding flux to analyze pure Na 2 SO 4 Powder (purity ≥ 99%), by mass ratio: Na 2 SO 4 Powder / raw material mixed powder = 4 for weighing and mixing, adding 75g of absolut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com