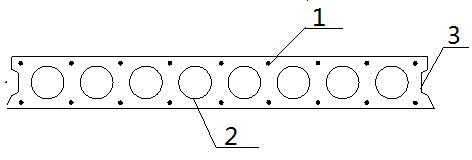

Assembly-type pre-stress hollow deck slab and preparation method thereof

A prestressed, hollow bridge technology, applied in the field of hollow bridge decks, can solve the problems of weak brittleness, unsuitable for production requirements, such as self-weight, etc., to improve wear resistance, improve life cycle, overcome brittle structure and poor impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] An assembled prestressed hollow bridge deck is poured with ultra-high-performance powder concrete, and the ultra-high-performance powder concrete includes the following components in parts by weight:

[0067] 800 parts of 42.5 grade ordinary Portland cement with an average particle size of 30-60 μm;

[0068] 150 parts of micro-silicon powder with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0069] 150 parts of limestone powder with an average particle size of 10-30 μm;

[0070] 30 parts of nanometer calcium carbonate powder;

[0071] 850 parts of river sand with particle size below 1.63mm;

[0072] 18 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0073] 4 parts of self-curing agent;

[0074] 175 parts of water;

[0075] 120 copper-plated fibers with an average diameter of 0.20 mm and a length of 12 to 15 mm;

[0076] 60 steel fibers with an average diameter of 0.28mm and a length of 14-18mm;

[007...

Embodiment 2

[0089] Except that the parts by weight of the components of the ultra-high performance powder concrete are different, the others are the same as in Example 1;

[0090] An assembled prestressed hollow bridge deck is poured with ultra-high-performance powder concrete, and the ultra-high-performance powder concrete includes the following components in parts by weight:

[0091] 1,000 parts of 42.5 grade ordinary Portland cement with an average particle size of 30-60 μm;

[0092] 200 parts of micro-silicon powder with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0093] 200 parts of limestone powder with an average particle size of 10-30 μm;

[0094] 50 parts of nanoscale calcium carbonate powder;

[0095] 1000 parts of river sand with particle size below 1.63mm;

[0096] 25 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0097] 6 parts of self-curing agent;

[0098] 230 parts of water;

[0099] 120 copper-plat...

Embodiment 3

[0105] Except that the parts by weight of the components of the ultra-high performance powder concrete are different, the others are the same as in Example 1;

[0106] The ultra-high performance powder concrete includes the following components in parts by weight:

[0107] 850 parts of 42.5 grade ordinary Portland cement with an average particle size of 30-60 μm;

[0108] 170 parts of micro-silicon powder with an average particle size of 5-20 μm and a SiO2 content of ≥85%;

[0109] 170 parts of limestone powder with an average particle size of 10-30 μm;

[0110] 35 parts of nanoscale calcium carbonate powder;

[0111] 900 parts of river sand with particle size below 1.63mm;

[0112] 20 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0113] 4 parts of self-curing agent;

[0114] 195 parts of water;

[0115] 120 copper-plated fibers with an average diameter of 0.20 mm and a length of 12 to 15 mm;

[0116] 60 steel fibers with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com