Rapid culture method of simultaneous desulfidation and denitrogenation granular sludge

A cultivation method and technology of sulfur particles are applied in the field of rapid cultivation of granular sludge for simultaneous denitrification and sulfur removal, and can solve the problems of death of anammox bacteria, microbial activity and biomass restriction of treatment efficiency, and growth of anammox bacteria. Slow and other problems, to achieve the effect of low investment and operation cost, obvious sludge granularity, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

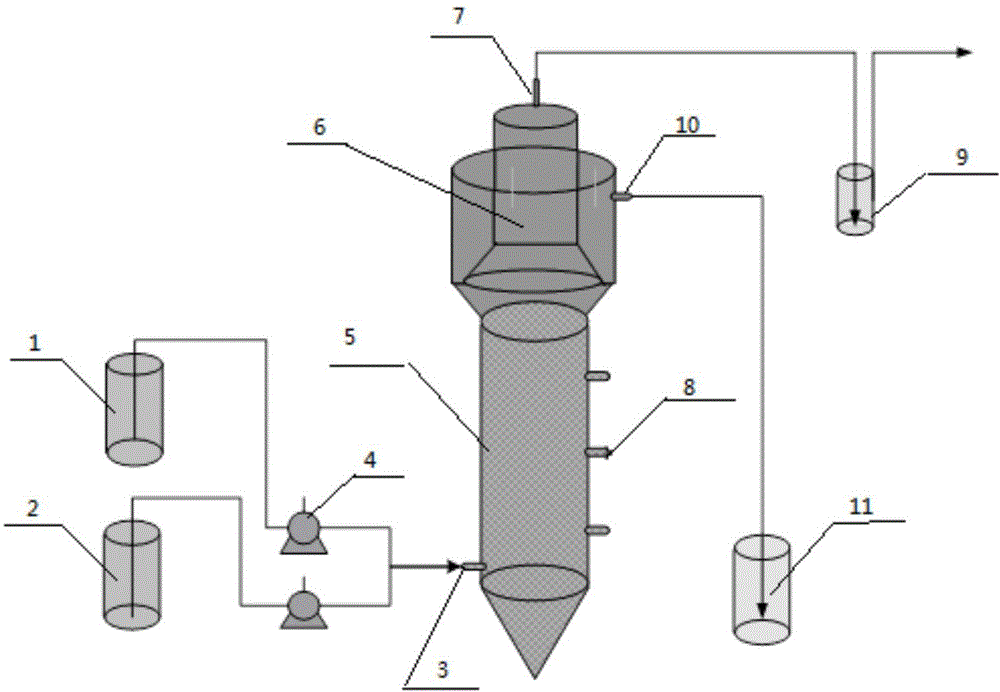

[0027] The rapid cultivation of a synchronous denitrification and desulfurization granular sludge of the present invention mainly includes two stages: the first stage is the synchronous denitrification and desulfurization sludge cultivation stage, the main purpose is the enrichment and screening of denitrification and desulfurization microorganisms ; The second stage is to realize the enrichment stage of high-efficiency denitrification and desulfurization granular sludge by changing the water quality and hydraulic load.

[0028] The first stage is the simultaneous denitrification and desulfurization sludge cultivation stage. The simulated wastewater containing inorganic salts, trace elements, and sulfides is used as the influent. The composition is as follows (the content of each component is calculated by the volume of simulated wastewater), inorganic salt: 0.027 g·L -1 KH 2 PO 4 , 0.3g·L -1 MgSO 4 ·7H 2 O, 0.14g L -1 CaCl 2 ;Trace element Ⅰ: EDTA6.25mg·L -1 , FeSO 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com