Method and device for modifying or regenerating SCR catalyst by utilizing lanthanum salt or cerium salt

A SCR catalyst and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high cost, harsh operating environment, time-consuming and consumption of SCR catalysts To solve problems such as power and other problems, to achieve the effect of widening the working temperature window, improving the anti-poisoning ability, saving time and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

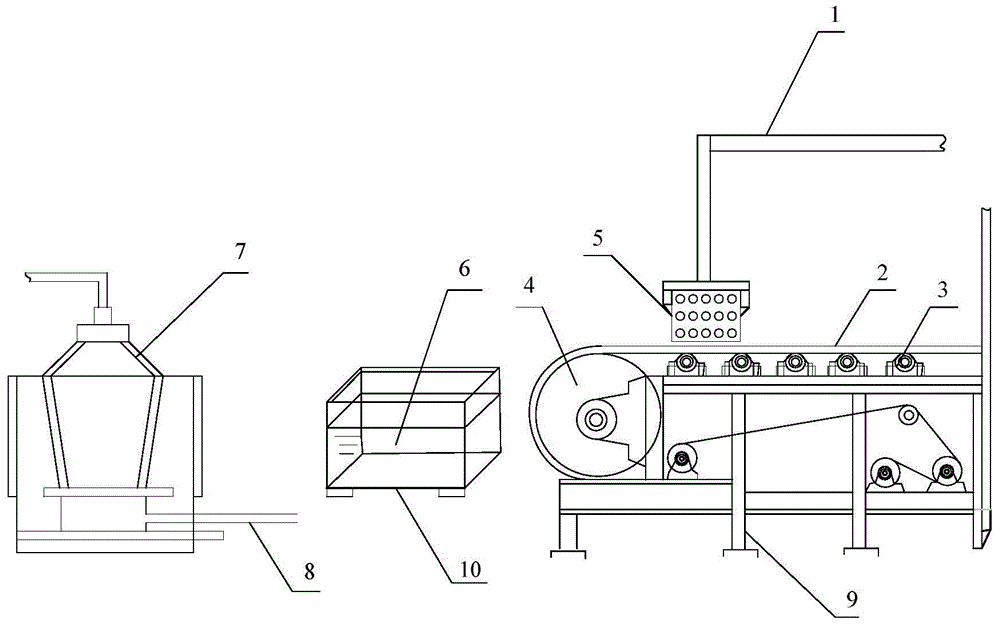

[0032] (1) 1g of cerium nitrate is added to 50ml of distilled water, stirred until completely dissolved to obtain an impregnation solution;

[0033] (2) Take 8.3 g of the SCR catalyst module deactivated by K poisoning and place it on the conveyor belt 2 and transport it to the impregnation solution made in step (1) for impregnation, first vibrate with ultrasonic waves for 10 minutes, and then let it stand for immersion for 4 hours;

[0034] (3) The mechanical gripper 1 takes out the impregnated catalyst module in step (2) and filters it dry, puts it in the material port 8 of the calciner 7, then sends it into the calciner 7, and in the calciner 7, it is heated in the air at 100-120°C. Dry in the atmosphere for 12h;

[0035](4) The catalyst dried in step (3) was calcined in an air atmosphere at 250° C. for 4 hours to obtain a cerium salt-modified SCR catalyst.

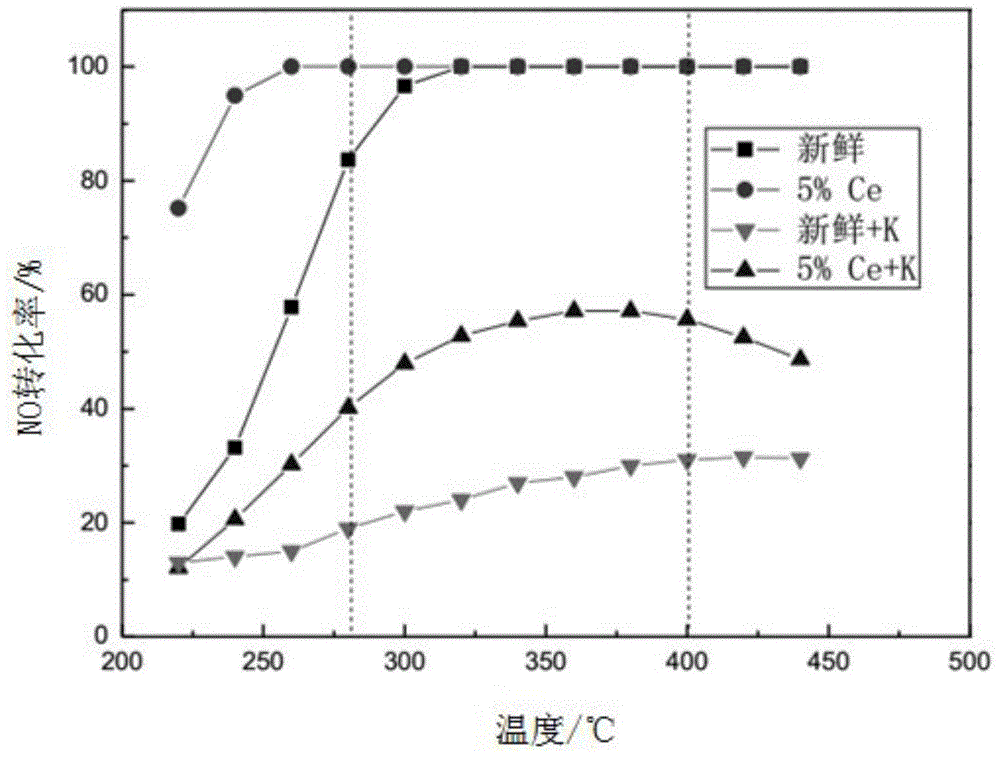

[0036] The SCR catalyst modified by cerium nitrate in this example is used for flue gas denitrification, and the spa...

Embodiment 2

[0038] (1) Add 1.2g of cerium nitrate into 50ml of distilled water, stir until completely dissolved, and obtain an impregnation solution;

[0039] (2) Place 10 g of fresh SCR catalyst modules on the conveyor belt 2 and transport them to the impregnation solution prepared in step (1) for immersion, first bubbling and shaking for 10 minutes, then standing and soaking for 4.5 hours;

[0040] (3) The mechanical gripper 1 takes out the impregnated catalyst module in step (2) and filters it dry, puts it in the material port 8 of the calciner 7, then sends it into the calciner 7, and in the calciner 7, it is heated in the air at 100-120°C. Dry in the atmosphere for 12h;

[0041] (4) The catalyst dried in step (3) was calcined in an air atmosphere at 325° C. for 4.5 hours to obtain a cerium salt-modified SCR catalyst.

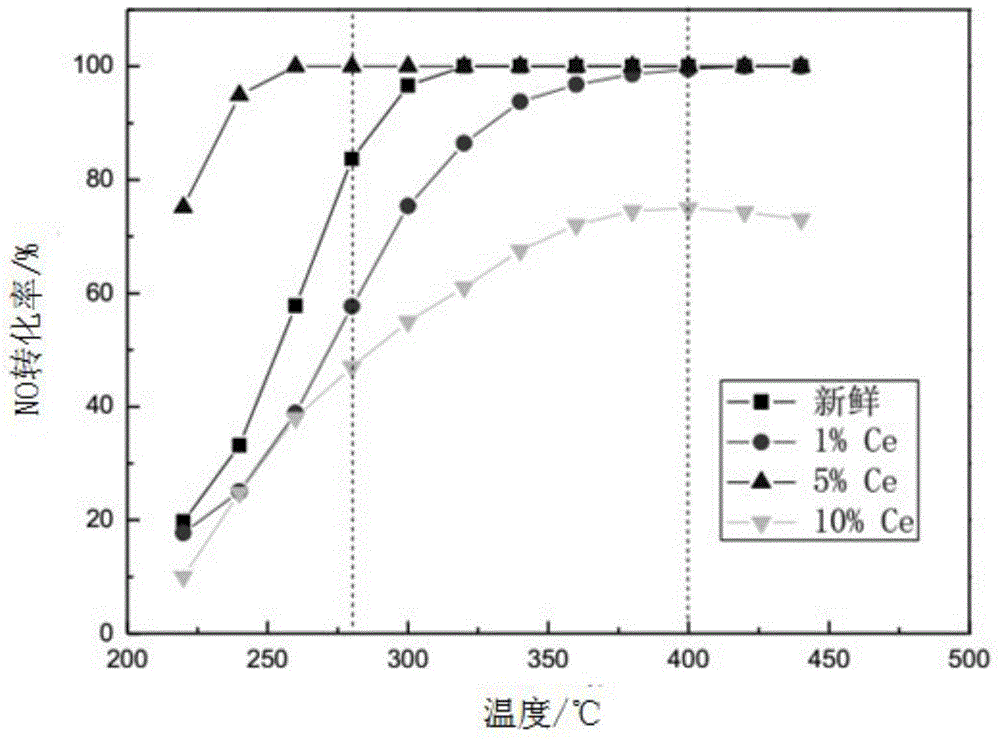

[0042] The SCR catalyst modified by cerium nitrate in this example is used for flue gas denitrification, and the space velocity ratio is 6500h -1 , the flue gas NOX ...

Embodiment 3

[0044] (1) 1.25g of cerium nitrate was added into 50ml of distilled water, and stirred until completely dissolved to obtain an impregnation solution;

[0045] (2) Place 7.6 g of the composite poisoned and deactivated SCR catalyst module on the conveyor belt 2 and transport it to the impregnation solution prepared in step (1) for impregnation, first bubbling and shaking for 12 minutes, and then standing for 5 hours;

[0046] (3) The mechanical gripper 1 takes out the impregnated catalyst module in step (2) and filters it dry, puts it in the material port 8 of the calciner 7, then sends it into the calciner 7, and in the calciner 7, it is heated in the air at 100-120°C. Dry in the atmosphere for 12h;

[0047] (4) Calcining the dried catalyst in step (3) in an air atmosphere at 400° C. for 5 hours to obtain a cerium salt-modified SCR catalyst.

[0048] The SCR catalyst modified by cerium nitrate in this example is used for flue gas denitrification, and the space velocity ratio i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com