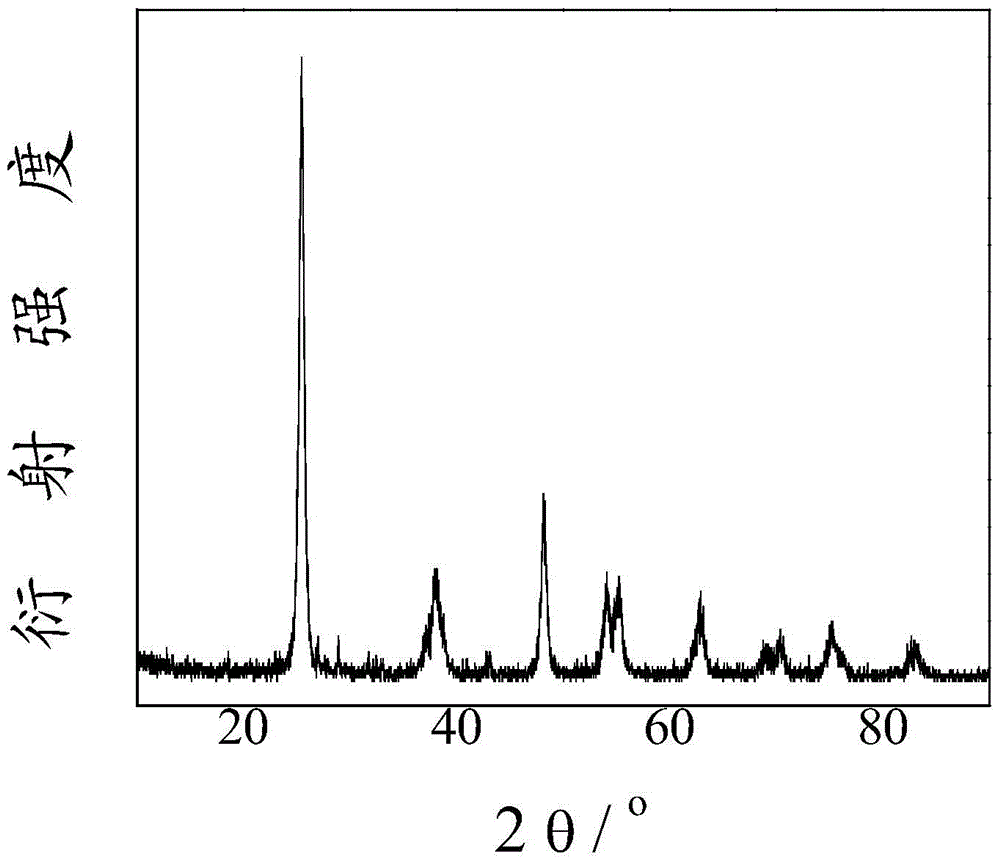

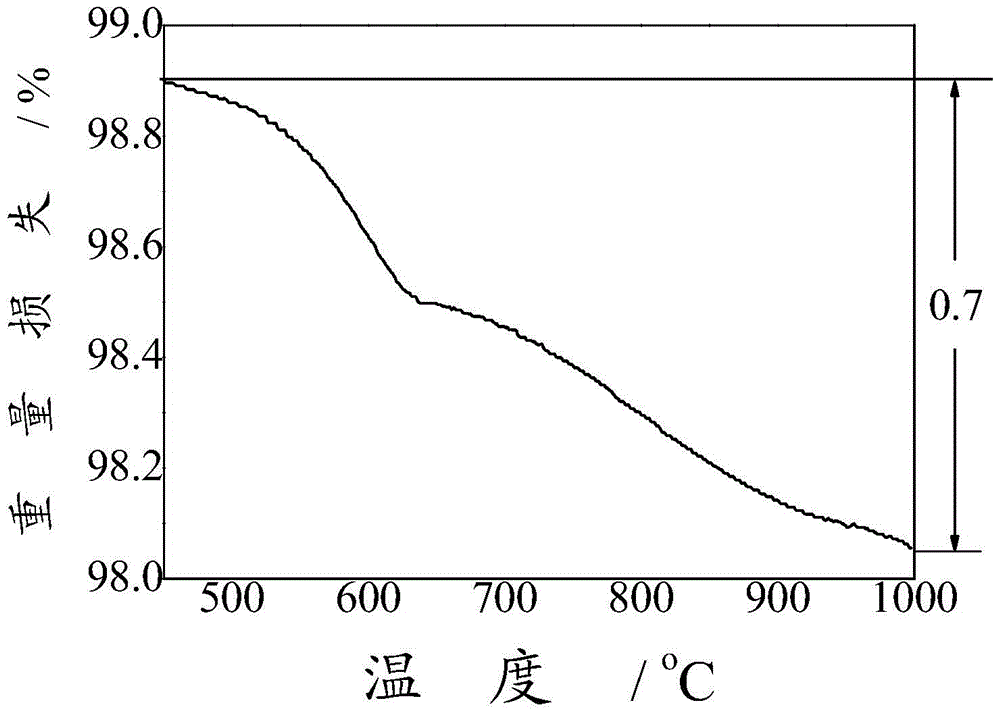

A tio for denitrification 2 -wo 3 -baso 4 Composite powder and its preparation method

A composite powder, tio2-wo3-baso4 technology, applied in the field of environmental protection, can solve the problems of denitration catalyst specific surface area reduction, weaken denitrification catalytic activity, etc., and achieve the effect of simple operation and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] WO 3 Content is 3wt%, BaSO 4 3 wt% TiO 2 -WO 3 -BaSO 4 Preparation of composite powders.

[0034] Step 1: 600 g of metatitanic acid solid was dissolved in 500 g of distilled water and stirred for 1 hour to obtain a metatitanic acid slurry.

[0035] Step 2: Mix and transfer ammonium paratungstate and barium sulfate to the slurry in step 1, and continue stirring for 30 minutes to obtain a mixed slurry of metatitanic acid, ammonium paratungstate and barium sulfate.

[0036] Step 3: Slowly add analytically pure ammonia solution dropwise to the mixed slurry in step 2, adjust the pH of the solution until the pH of the solution is 7, and continue stirring for 2 hours to obtain a titanium tungsten barium suspension.

[0037] Step 4: Put the obtained titanium-tungsten-barium mixture into an oven for direct drying, the drying temperature is 120° C., and the drying time is 24 hours.

[0038] Step 5: Put the obtained dry material into a rotary kiln for calcination. The calci...

Embodiment 2

[0047] WO 3 Content is 2wt%, BaSO 4 10wt% TiO 2 -WO 3 -BaSO 4 Preparation of composite powders.

[0048] Step 1: 40 g of metatitanic acid solid was dissolved in 100 g of distilled water and stirred for 1 hour to obtain a metatitanic acid slurry.

[0049] Step 2: Mix and transfer ammonium paratungstate and barium sulfate to the slurry in step 1, and continue stirring at 60°C for 30 minutes to obtain a mixed slurry of metatitanic acid, ammonium paratungstate and barium sulfate.

[0050] Step 3: Slowly add analytically pure ammonia solution dropwise to the mixed slurry in step 2, adjust the pH of the solution until the pH of the solution is = 11, and continue stirring for 2 hours to obtain a titanium tungsten barium suspension.

[0051] Step 4: Dry the obtained titanium-tungsten-barium mixture in a vacuum rake dryer at a temperature of 70°C, a rotation speed of 15r / min, a vacuum of 350Pa, and a drying time of 24 hours.

[0052] Step 5: Put the obtained dry material into a r...

Embodiment 3

[0055] WO 3 Content is 10wt%, BaSO 4 6 wt% TiO 2 -WO 3 -BaSO 4 Preparation of composite powders.

[0056] Step 1: 50 g of metatitanic acid solid was dissolved in 100 g of distilled water and stirred for 1 hour to obtain a metatitanic acid slurry.

[0057] Step 2: Mix and transfer ammonium paratungstate and barium sulfate to the slurry in step 1, and continue stirring at 110°C for 30 minutes to obtain a mixed slurry of metatitanic acid, ammonium paratungstate and barium sulfate.

[0058] Step 3: Slowly add analytically pure ammonia solution dropwise to the mixed slurry in step 2, adjust the pH of the solution until the pH of the solution is 8, and continue stirring for 2 hours to obtain a titanium tungsten barium suspension.

[0059] Step 4: Put the obtained titanium-tungsten-barium mixture into an oven for direct drying, the drying temperature is 100°C, and the drying time is 24 hours.

[0060] Step 5: Put the obtained dry material into a rotary kiln for calcination. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com