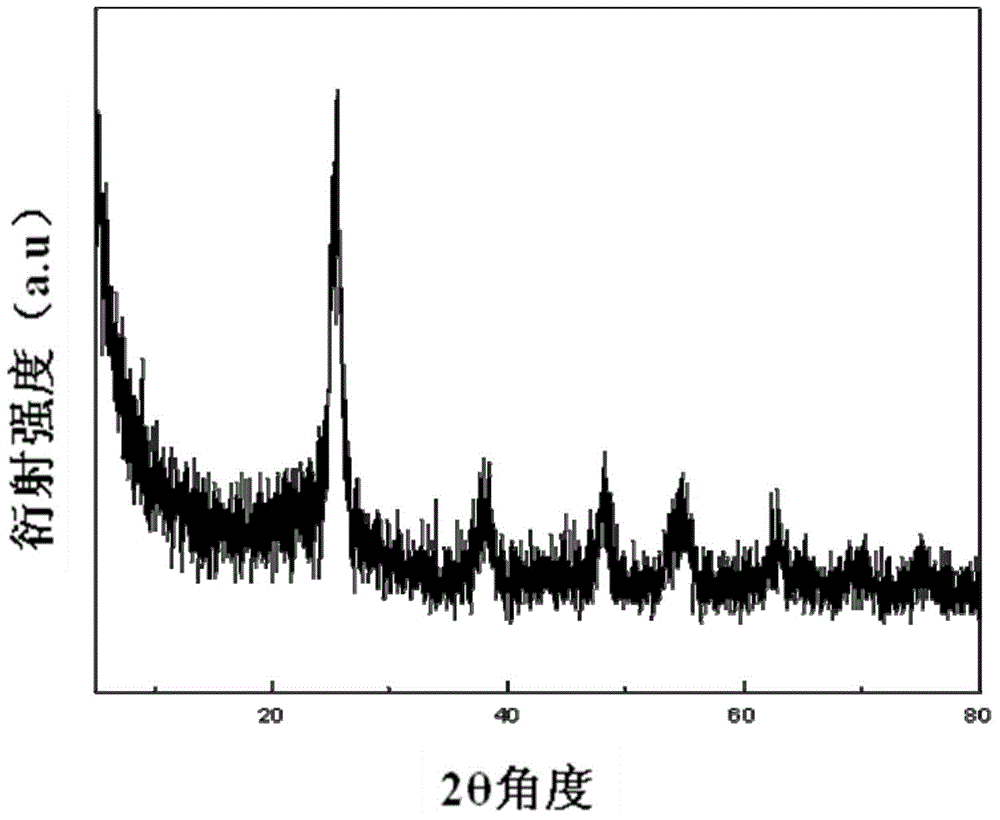

Activated carbon fiber loading titanium dioxide composite photocatalytic material and preparation method and application thereof

A technology of activated carbon fiber and composite photocatalysis, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc. Ideal, poor synergistic effect and other problems, to achieve the effect of improving photocatalytic activity and reusability, improving binding rate and binding firmness, and reducing deposition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

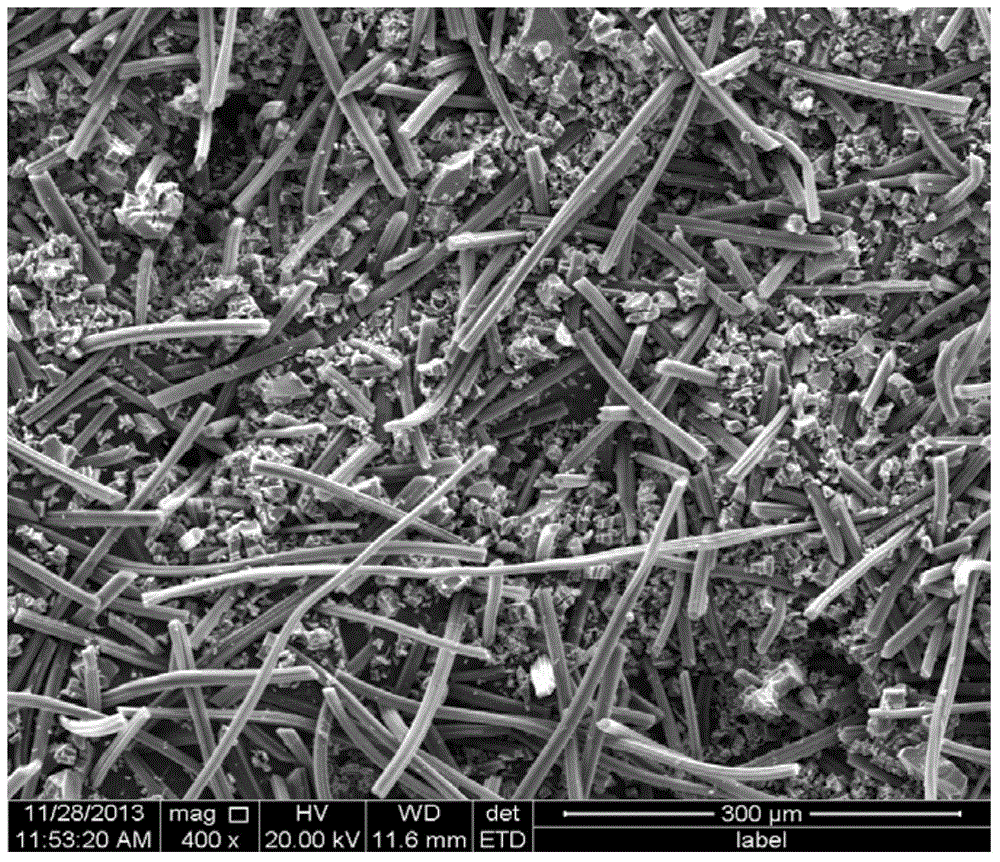

Embodiment 1

[0035] Prepare activated carbon fiber-loaded titanium dioxide composite photocatalytic material according to the following steps:

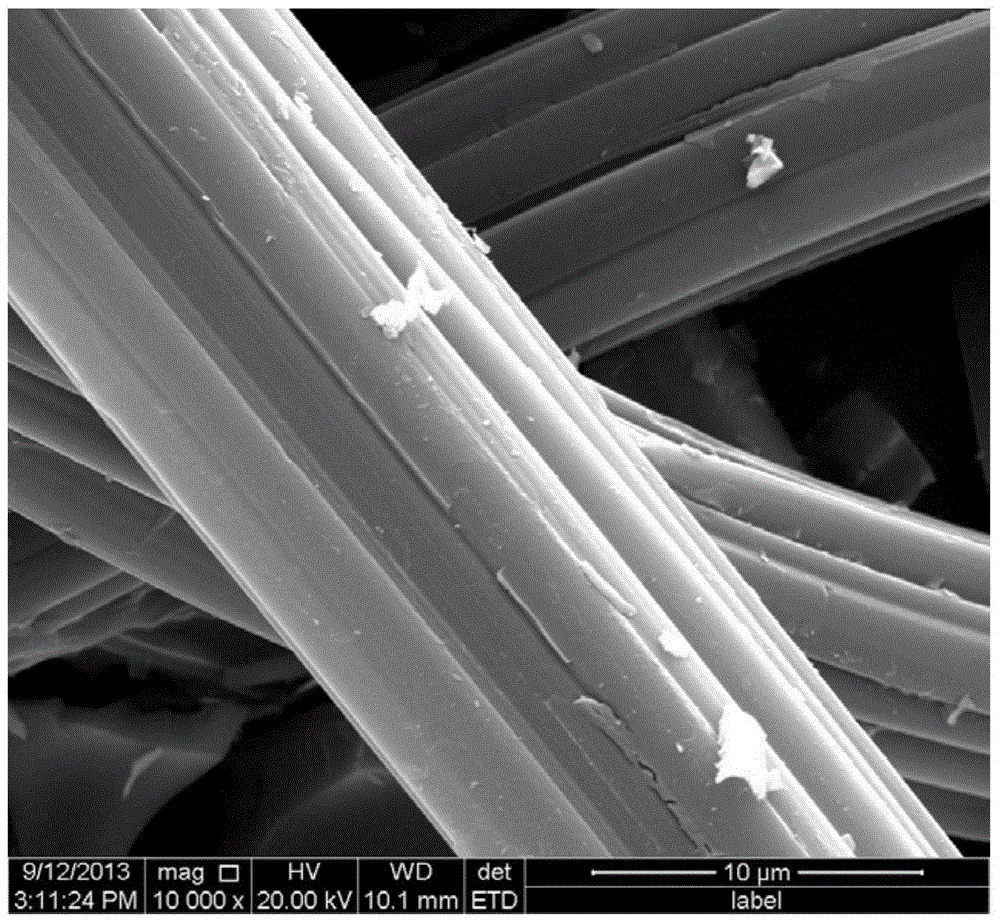

[0036] (1) Take the specific surface area as 1500m 2 / g of activated carbon fibers, cut to a cross-section of 2cm×2cm; soak in absolute ethanol, 0.5mol / L sodium hydroxide solution, and dilute nitric acid solution for 30min, wash with deionized water, and dry at 120°C for 24h. Get the activated carbon fiber after pretreatment;

[0037](2) Take 38.9ml of absolute ethanol, mix it with 56.7ml of tetrabutyl titanate and 5.2ml of acetylacetone, and stir thoroughly to obtain solution A; then take 19.4ml of absolute ethanol, adjust the pH to 10 with 12ml of methylamine Mix with deionized water and stir thoroughly to obtain solution B; under stirring conditions, slowly add solution B to solution A dropwise, and continue stirring at 35°C for 1 hour to obtain titanium dioxide sol;

[0038] (3) Take 6g of activated carbon fibers pretreated in step (1), and ...

Embodiment 2

[0042] (1) Take the specific surface area as 1500m 2 / g of activated carbon fibers, cut to a cross-section of 3cm×3cm; soak in absolute ethanol, 0.5mol / L sodium hydroxide solution, and dilute nitric acid solution for 30min, wash with deionized water, and dry at 120°C for 24h. Get the activated carbon fiber after pretreatment;

[0043] (2) Take 13ml of absolute ethanol, mix it with 18.9ml of tetrabutyl titanate and 1.7ml of acetylacetone, and stir thoroughly to obtain solution A; then take 6.5ml of absolute ethanol, mix it with 4ml of the Mix deionized water and stir thoroughly to obtain solution B; under stirring conditions, slowly add solution B to solution A dropwise, and continue stirring at 35°C for 1 hour to obtain titanium dioxide sol;

[0044] (3) Take 2g of the activated carbon fiber pretreated in step (1), and immerse it in the titania sol obtained in step (2); at 45°C, treat it with an ultrasonic wave with a frequency of 40kHz for 30min, and leave it to age at a con...

Embodiment 3

[0047] (1) Take the specific surface area as 1500m 2 / g of activated carbon fibers, cut to a cross-section of 4cm×4cm; soak in absolute ethanol, 0.5mol / L sodium hydroxide solution, and dilute nitric acid solution for 30min, wash with deionized water, and dry at 120°C for 24h. Get the activated carbon fiber after pretreatment;

[0048] (2) Take 38.9ml of absolute ethanol, mix it with 56.7ml of tetrabutyl titanate and 5.2ml of acetylacetone, and stir thoroughly to obtain solution A; then take 19.4ml of absolute ethanol, adjust the pH to 10 with 12ml of methylamine Mix with deionized water and stir thoroughly to obtain solution B; under stirring conditions, slowly add solution B to solution A dropwise, and continue stirring at 35°C for 1 hour to obtain titanium dioxide sol;

[0049] (3) Get 6g of activated carbon fibers pretreated in step (1), and immerse them in the titania sol obtained in step (2); under the condition of 55° C., treat them with an ultrasonic wave with a freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com