Method for realizing chemical plated antenna on plastic housing embedded with metal

A technology for plastic shells and metal parts, which is applied in liquid chemical plating, metal material coating technology, electrophoretic plating, etc., can solve the problems of metal parts corrosion and failure to achieve the function of metal parts, achieve improved strength, and is economical and practical high efficiency and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

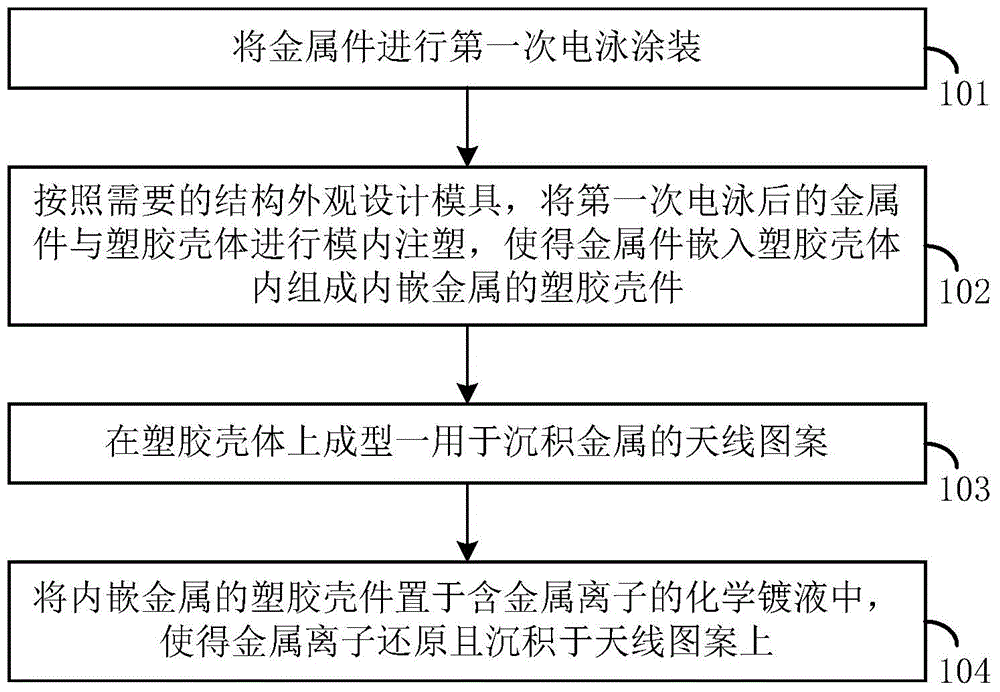

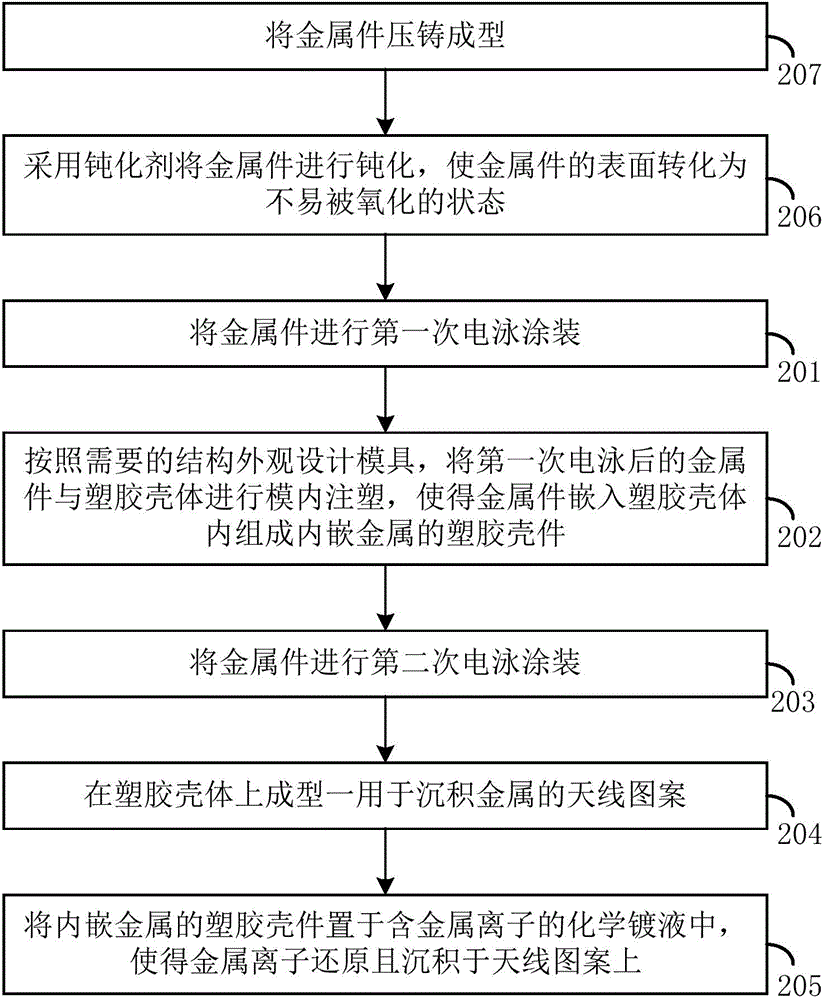

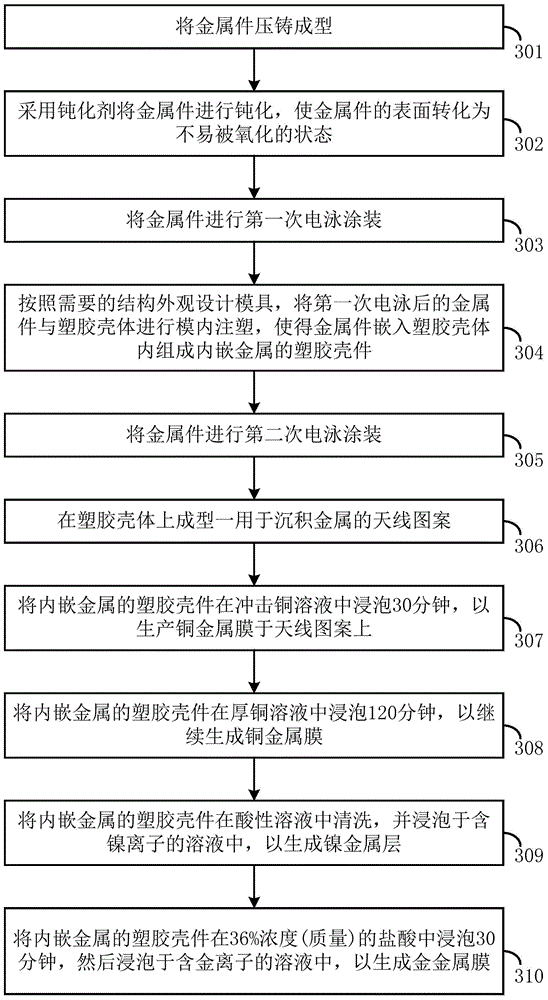

[0041] see figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the method provided by the present invention. The method includes:

[0042] Step 101: performing electrophoretic coating on the metal parts for the first time;

[0043] The metal piece may be any metal or a combination of at least two metals in alloy or non-alloy form.

[0044] Electrophoretic technology is the electrophoretic paint (or electrophoretic paint solution) electrolyzed into charged paint ions under the action of negative and positive poles and applied voltage, and moves to the opposite electrode, and finally deposits the technology of electrophoretic paint film. It includes anodic electrophoresis process and cathodic electrophoresis process. The object to be coated is used as an anode and cathode respectively, and negatively charged and positively ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com