A kind of highly stable modified water-based phenolic resin anticorrosion coating and its preparation method

A water-based phenolic resin and anti-corrosion coating technology, which is applied in anti-corrosion coatings, hyaluronic acid coatings, chitin polysaccharide coatings, etc., can solve the problem of loss of performance of phenolic resin anti-corrosion materials, incompatibility of phenolic resin and water-based latex, and phenolic resin chemistry. Unstable performance and other problems, to achieve the effect of improving practicability and scope of application, enhancing chemical stability and acid and alkali resistance, and improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

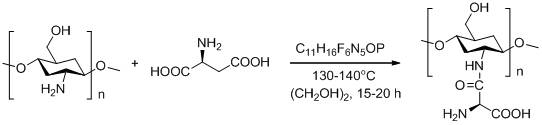

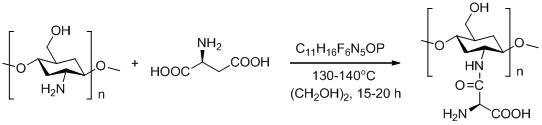

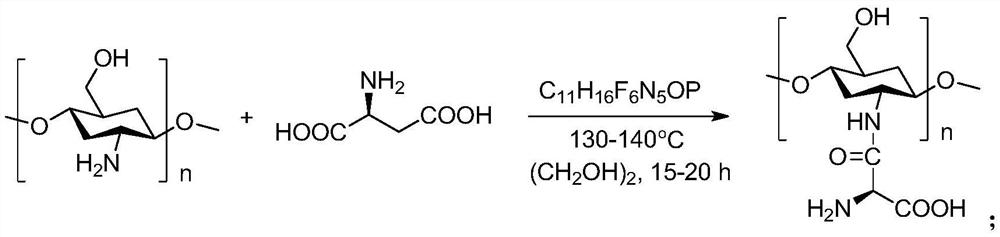

[0030] (1) Preparation of chitosan-L-aspartic acid peptide The preparation method is as follows: add 600 mL of ethylene glycol into the reaction bottle, then weigh 48 parts of chitosan and 25 parts of L-aspartic acid and stir After uniformity, slowly add 27 parts of condensing agent benzotriazole- N , N , N ', N '-Tetramethylurea hexafluorophosphate, heat the reaction bottle in a constant temperature water bath to 130 °C, stir at a constant speed for 15 h, after the reaction, cool the reaction bottle to room temperature, filter the solution to remove the solvent to obtain a white solid flocculent Wash the solid flocs with an appropriate amount of distilled water and absolute ethanol in sequence until the impurities and reaction by-products are completely removed, put the cleaned product in an oven and heat it to 90 °C, and dry the water for 8 hours to obtain chitosan- L-Aspartate Peptide Component 1.

[0031] (2) Preparation of chitosan-L-aspartic acid peptide loaded MoSe ...

Embodiment 2

[0034] (1) Preparation of chitosan-L-aspartic acid peptide The preparation method is as follows: Add 600 mL of ethylene glycol into the reaction bottle, then weigh 49 parts of chitosan and 26 parts of L-aspartic acid and stir After uniformity, slowly add 25 parts of condensing agent benzotriazole- N , N , N ', N '-Tetramethyluronium hexafluorophosphate, heat the reaction bottle in a constant temperature water bath to 135 °C, stir at a constant speed for 18 h, after the reaction, cool the reaction bottle to room temperature, filter the solution to remove the solvent to obtain a white solid floc Wash the solid flocs with an appropriate amount of distilled water and absolute ethanol in sequence until the impurities and reaction by-products are completely removed, put the cleaned product in an oven and heat it to 100 °C, and dry the water for 7 hours to obtain chitosan- L-Aspartate Peptide Component 2.

[0035] (2) Preparation of chitosan-L-aspartic acid peptide loaded MoSe by...

Embodiment 3

[0038] (1) Preparation of chitosan-L-aspartic acid peptide The preparation method is as follows: add 700 mL of ethylene glycol into the reaction bottle, then weigh 50 parts of chitosan and 27 parts of L-aspartic acid and stir After uniformity, slowly add 23 parts of condensing agent benzotriazole- N , N , N ', N '-Tetramethyluronium hexafluorophosphate, heat the reaction bottle in a constant temperature water bath to 135 °C, stir at a constant speed for 18 h, after the reaction, cool the reaction bottle to room temperature, filter the solution to remove the solvent to obtain a white solid floc Wash the solid flocs with an appropriate amount of distilled water and absolute ethanol in sequence until the impurities and reaction by-products are completely removed, put the cleaned product in an oven and heat it to 100 °C, and dry the water for 6 h to obtain chitosan- L-Aspartate Peptide Component 3.

[0039] (2) Preparation of chitosan-L-aspartic acid peptide loaded MoSe by hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com