A kind of lithium ion battery electrolyte additive and lithium ion battery electrolyte

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as reducing the cycle performance of lithium-ion batteries, affecting the performance of lithium-ion batteries, and reducing battery capacity, so as to improve battery cycle performance, improve high-voltage cycle performance, Effect of extending battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

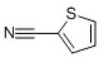

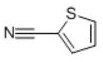

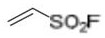

[0019] A lithium ion battery electrolyte includes additives, a non-aqueous organic solvent, and a lithium salt; the non-aqueous organic solvent is composed of ethylene carbonate and dimethyl carbonate with a mass ratio of 4:6; the lithium salt is LiPF 6 , its molar concentration in the electrolyte is 1.05mol / L, the additive is composed of 2-thiophenecarbonitrile and vinylsulfonyl fluoride additive, the mass of the additive is 5% of the mass of the electrolyte, 2-thiophenecarbonitrile and vinyl The mass ratio of sulfonyl fluoride is 1:1.5.

[0020] The preparation of the electrolyte was carried out in an argon glove box (moisture 6 It is dissolved in the above mixed organic solvent, and then 2-thiophenecarbonitrile and vinylsulfonyl fluoride are sequentially added thereto, and the electrolyte solution is obtained after stirring uniformly.

[0021] The lithium-ion battery electrolyte prepared in this example contains additives: 2-thiophenecarbonitrile and vinylsulfonyl fluoride....

Embodiment 2

[0023] A lithium ion battery electrolyte, comprising additives, a non-aqueous organic solvent and a lithium salt; the non-aqueous organic solvent is composed of ethylene carbonate, ethyl methyl carbonate and dimethyl carbonate in a mass ratio of 1:1:1; the lithium salt for LiBF 4 , its molar concentration in the electrolyte is 1.0mol / L, the additive is composed of 2-thiophenecarbonitrile and vinylsulfonyl fluoride additive, the mass of the additive is 0.5% of the mass of the electrolyte, 2-thiophenecarbonitrile and vinyl The mass ratio of sulfonyl fluoride is 1:0.5.

[0024] The preparation of the electrolyte was carried out in an argon glove box (moisture 6 It is dissolved in the above mixed organic solvent, and then 2-thiophenecarbonitrile and vinylsulfonyl fluoride are sequentially added thereto, and the electrolyte solution is obtained after stirring uniformly.

[0025] The lithium-ion battery electrolyte prepared in this example contains additives: 2-thiophenecarbonitril...

Embodiment 3

[0027] A lithium ion battery electrolyte includes additives, a non-aqueous organic solvent and a lithium salt; the non-aqueous organic solvent is composed of ethylene carbonate, ethyl acetate and diethyl carbonate in a mass ratio of 1:1:1; the lithium salt is LiPF 6 , its molar concentration in the electrolyte is 1.0mol / L, the additive is composed of 2-thiophenecarbonitrile and vinylsulfonyl fluoride additive, the mass of the additive is 0.5% of the mass of the electrolyte, 2-thiophenecarbonitrile and vinyl The mass ratio of sulfonyl fluoride is 1:0.5.

[0028] The preparation of the electrolyte was carried out in an argon glove box (moisture 6 It is dissolved in the above mixed organic solvent, and then 2-thiophenecarbonitrile and vinylsulfonyl fluoride are sequentially added thereto, and the electrolyte solution is obtained after stirring uniformly.

[0029] The lithium-ion battery electrolyte prepared in this example contains additives: 2-thiophenecarbonitrile and vinylsul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com