A kind of animal bone-based graphene-like lithium-ion battery negative electrode material and preparation method thereof

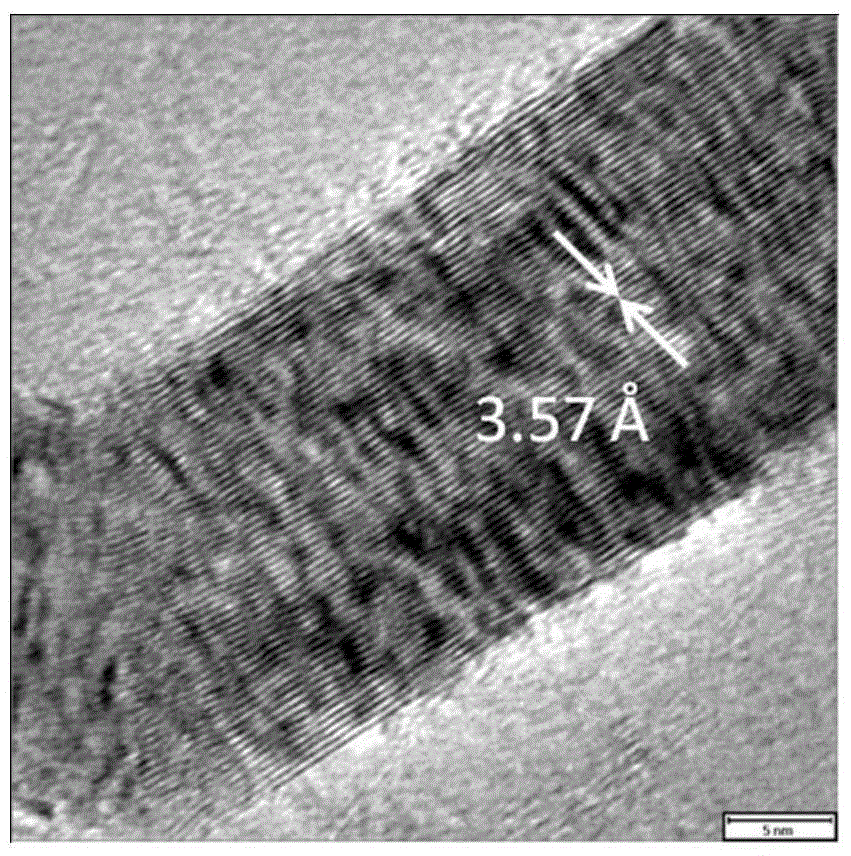

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex graphene preparation process and high cost, and achieve improved electrochemical performance and large interplanar spacing. , the effect of facilitating insertion and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A: Preparation of precursors:

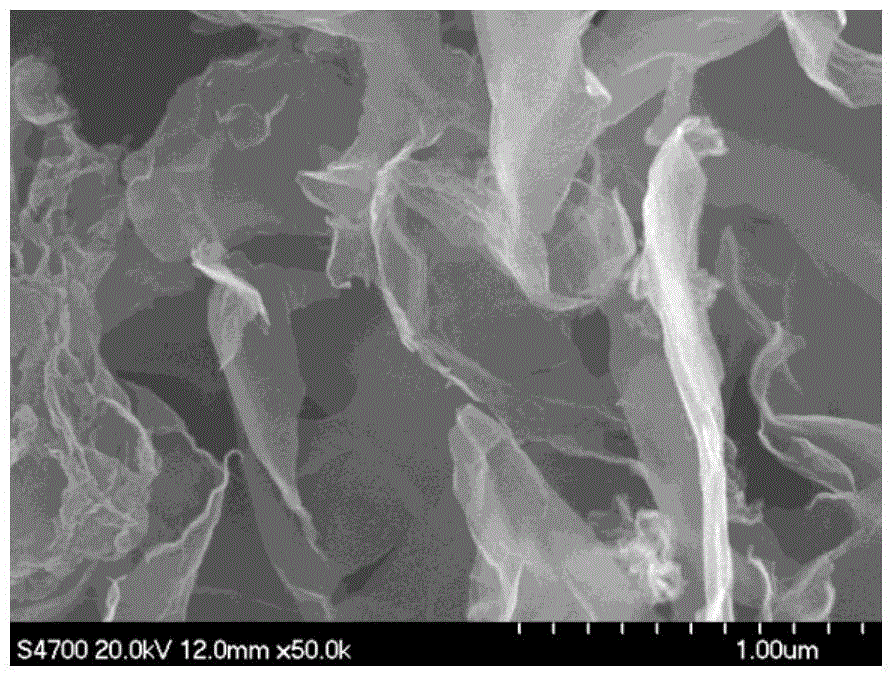

[0035] Under the protection of nitrogen, the pig bone was kept at 450°C for 6 hours for pre-carbonization; the pre-carbonized pig bone and KOH solid powder were mixed evenly at a mass ratio of 1:1, and the temperature was gradually raised to 850°C under the protection of nitrogen. , and kept for 1h, activated carbonization; then naturally cooled to room temperature under the protection of nitrogen, with 1mol / L HNO 3 The solution is acid-washed to remove inorganic salts therein, then washed with deionized water until neutral, and dried to obtain porous carbon.

[0036] B: Graphitization of precursors:

[0037] The specific steps are as follows: 1) Increase the temperature from room temperature to 1000 °C with a heating rate of 25 °C min -1 , keep warm for 30min; 2) Raise the temperature from 1000 to 2000°C at a rate of 20°C min -1 , keep warm for 30min; 3) Raise the temperature from 2000 to 2800°C at a rate of 10°C min -1 , constant te...

Embodiment 2

[0041] The preparation of the animal bone-based graphene-like negative electrode is the same as in Example 1.

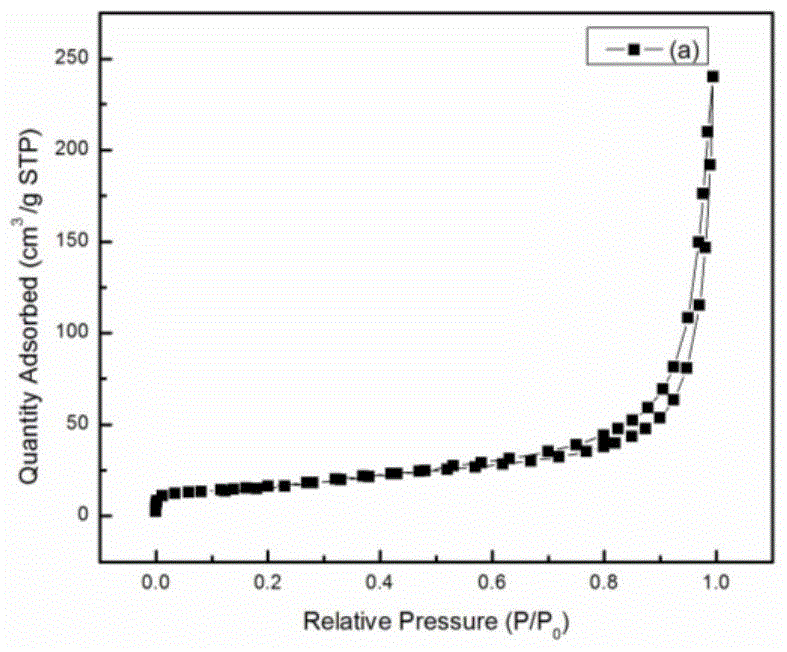

[0042] Use lithium sheet as negative electrode, choose polypropylene as diaphragm, choose 1mol L -1 Lithium hexafluorophosphate is used as the electrolyte, and the solvent volume ratio is ethylene carbonate: ethyl methyl carbonate: dimethyl carbonate = 1:1:1, and assembled into a CR2025 button battery. The charge and discharge cut-off voltages are 0.005V and 3V respectively, and the current density is 100mA g -1 Under the following conditions, the specific discharge capacity of the battery increases with the increase of the number of cycles. After 100 cycles, the specific discharge capacity of the battery is 363mAh g -1 , Coulombic efficiency is 99.7%.

Embodiment 3

[0044] A: Preparation of precursors:

[0045] Under the protection of nitrogen, the dried fish scales were kept at 450°C for 6 hours for pre-carbonization; the pre-carbonized fish scales and KOH solid powder were mixed evenly at a mass ratio of 1:1, and the temperature was gradually raised to 850°C under the protection of nitrogen. And keep it for 1h, carry out activated carbonization; then naturally cool to room temperature under the protection of nitrogen, and use 1mol / L HNO 3 The solution is acid-washed to remove inorganic salts therein, then washed with deionized water until neutral, and dried to obtain porous carbon.

[0046] B: Graphitization of precursors:

[0047] The specific steps are as follows: 1) Increase the temperature from room temperature to 1000 °C with a heating rate of 25 °C min -1 , keep warm for 30min; 2) Raise the temperature from 1000 to 2000°C at a rate of 20°C min -1 , keep warm for 30min; 3) Raise the temperature from 2000 to 2800°C at a rate of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com