A kind of oxyfluoride fluorescent powder and preparation method thereof

A technology of oxyfluoride and fluorescent powder, which is applied in the field of oxyfluoride fluorescent powder and its preparation, can solve problems such as the solid solution of optically active elements that are not mentioned, and achieve excellent luminous performance, simple preparation method, and convenient industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

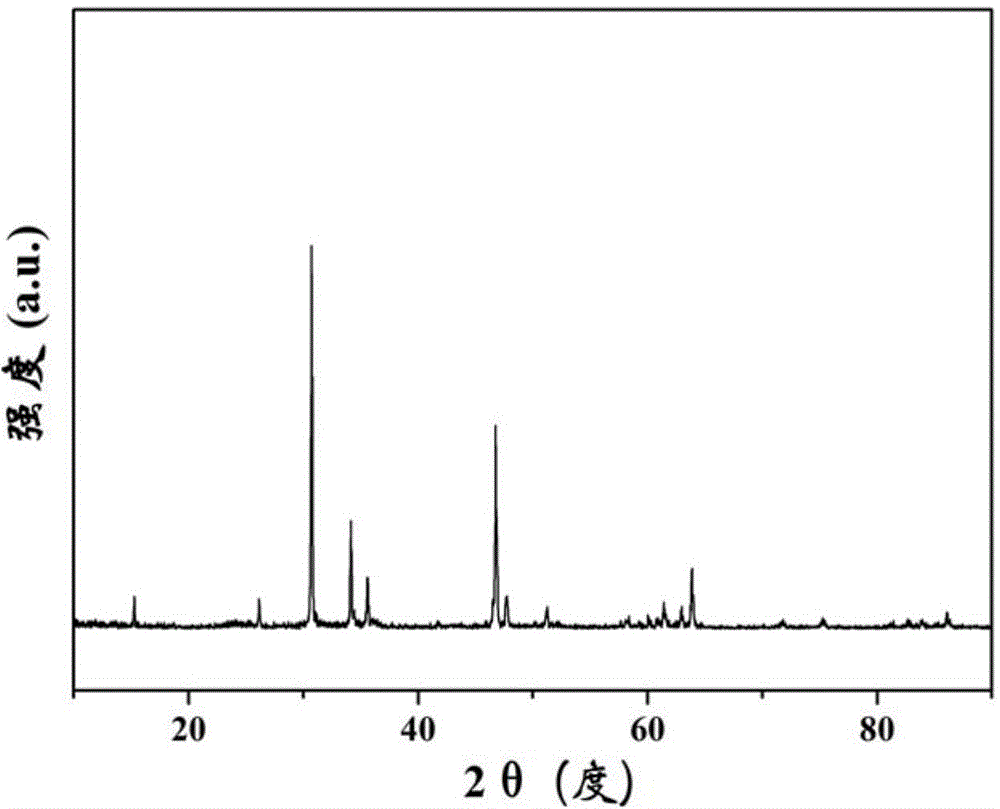

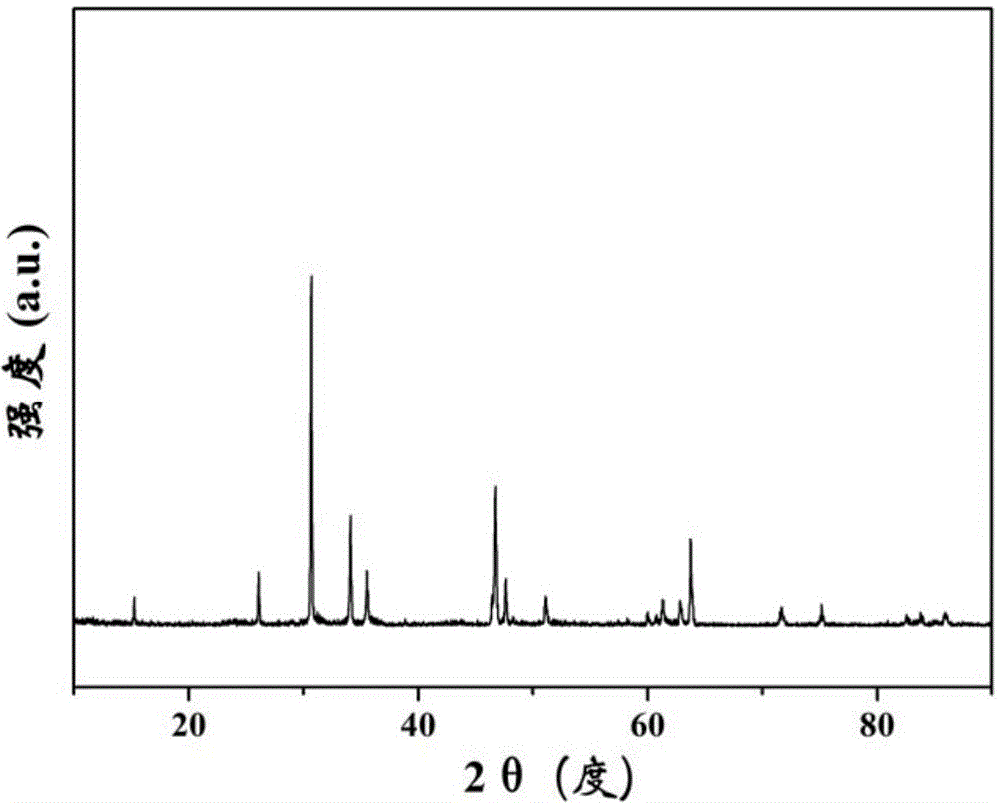

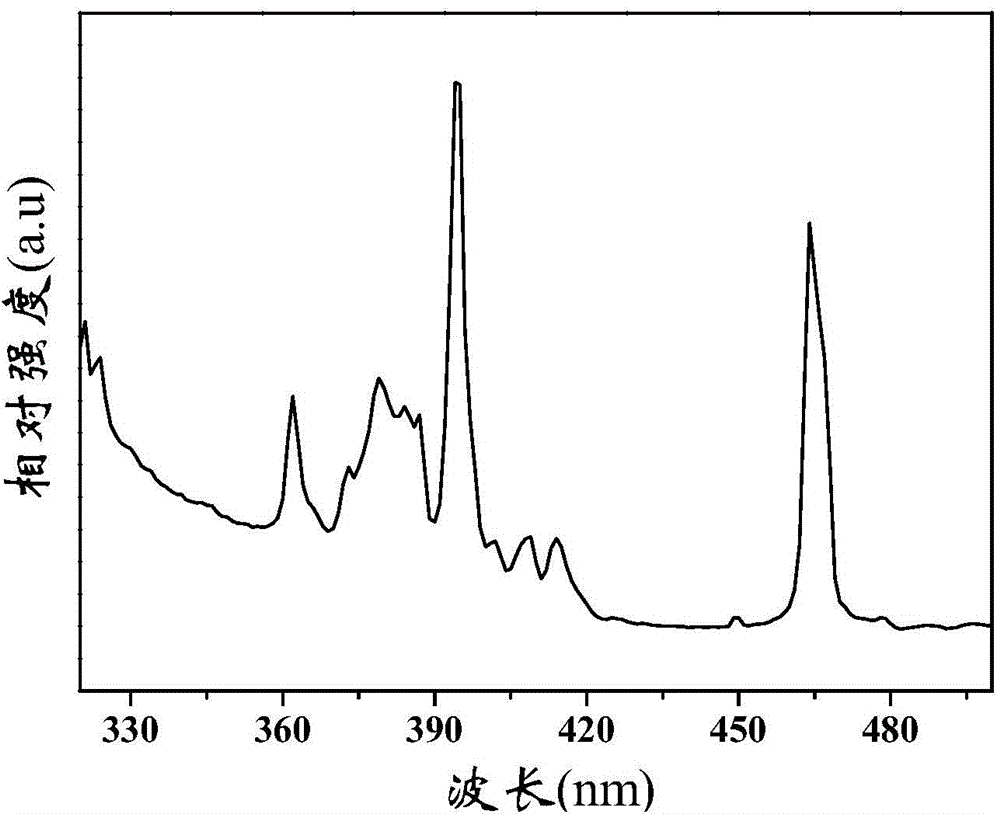

[0037] Weigh BaCO 3 14.2082g, Sc 2 o 3 3.2409g, BaF 2 4.3831g, Eu 2 o 3 0.5279g, the above raw materials are all analytically pure. After the above raw materials are ground evenly, they are put into an alumina crucible and roasted twice in the air. The first roasting temperature is 1350°C and kept for 4 hours. Roasting, the calcining temperature is 1320 ℃ for 16 hours. The chemical composition of the roasted product is Ba 2 sc 0.94 o 3 F:Eu 0.06Phosphor powder, its X-ray powder diffraction pattern (Co target, λ = 0.178892nm) such as figure 2 As shown, its excitation spectrum (under 612nm monitoring) see image 3 , it can be seen from the excitation spectrum that the phosphor can be effectively excited by ultraviolet or blue light in the range of 280-480nm, and has strong excitation peaks around 395nm and 464nm. Its emission spectrum see Figure 4 , it can be seen from the figure that the main emission peak is around 612nm, and the luminous intensity under excitati...

Embodiment 2-4

[0039] The preparation of embodiment 2-4 fluorescent powder is to take raw material according to the chemical composition and stoichiometric ratio of embodiment 2-4 in the table, prepare corresponding fluorescent powder according to the method of embodiment 1, obtain the chemical formula and relative luminous intensity of fluorescent powder See Table 3.

Embodiment 5

[0041] Weigh CaCO 3 4.8542g, BaCO 3 4.6374g, Sc 2 o 3 3.4478g, BaF 2 4.3831g, Eu 2 o 3 0.3519g, the above raw materials are all analytically pure, after the above raw materials are ground evenly, put into an alumina crucible and roast in air, the roasting temperature is 1320 ℃ for 8 hours. The chemical composition of the roasted product is Ba 0.97 Ca 0.97 ScO 3 F:Eu 0.04 The phosphor powder has an excitation spectrum wavelength range of 280-480nm and a main emission peak at around 612nm. The luminous intensities under excitation at 395nm and 464nm are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com