Method for preparing nanoscale ferroferric oxide from steel pickling wastewater

A ferroferric oxide and steel pickling technology, which is applied to the oxides of sub-ferric iron, chemical instruments and methods, iron oxide/iron hydroxide, etc., can solve problems such as scabbing, waste of resources, and complicated process flow. Achieve the effect of reducing concentration and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

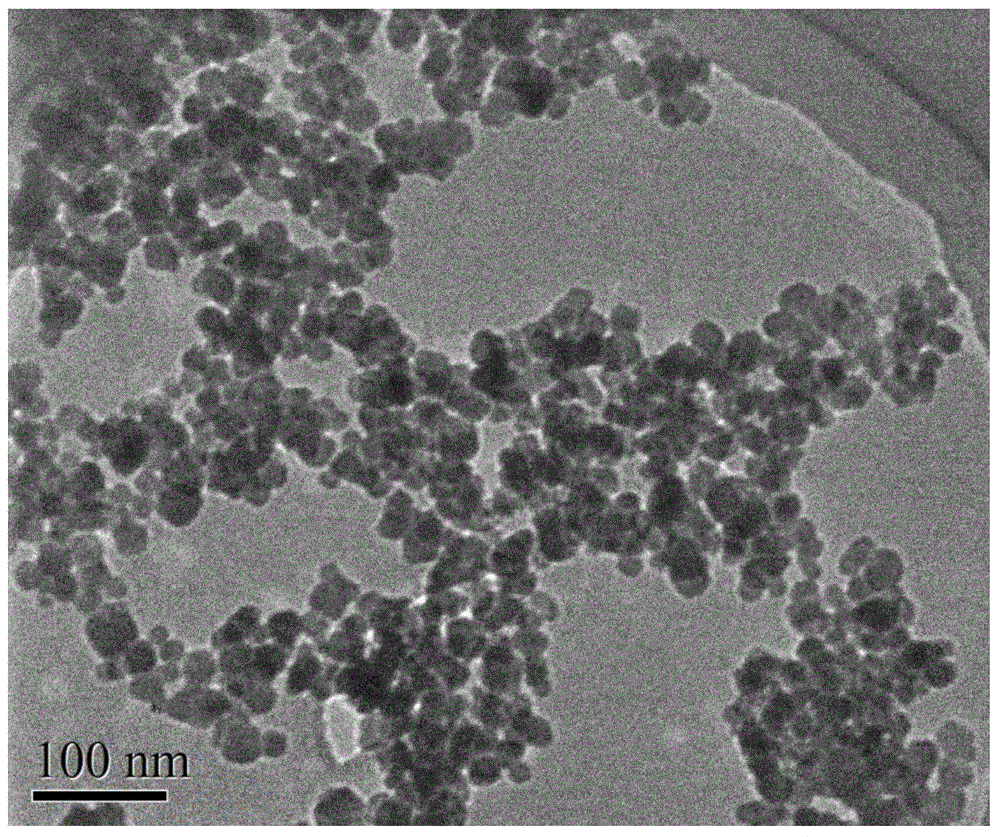

Image

Examples

Embodiment 1

[0025] The method for preparing nano-scale ferroferric oxide by iron and steel pickling wastewater consists of the following steps:

[0026] (1) Filter the steel pickling wastewater to remove suspended solids in the wastewater, and heat to 30°C;

[0027] (2) Add hydrogen peroxide to oxidize part of the ferrous ions in the waste water to ferric ions, and control the molar ratio of ferrous ions to ferric ions to be 1:1.7, stop adding hydrogen peroxide;

[0028] (3) add sodium citrate, control the concentration of sodium citrate in the waste water to be 1g / L;

[0029] (4) Add sodium hydroxide, after the pH value of waste water is adjusted to 10, stop adding sodium hydroxide; Add sodium metasilicate afterwards, the addition of sodium metasilicate is 2g / L;

[0030] (5) Continue heating the solution obtained in step (4) to 60° C., keep it warm for 1 hour, and then cool it naturally to room temperature;

[0031] (6) After solid-liquid separation, the obtained solid powder is washed...

Embodiment 2

[0033] The method for preparing nano-scale ferroferric oxide by iron and steel pickling wastewater consists of the following steps:

[0034] (1) Filtrate the steel pickling wastewater to remove suspended matter in the wastewater, and heat it to 40°C;

[0035] (2) Add hydrogen peroxide to oxidize part of the ferrous ions in the waste water into ferric ions, and control the molar ratio of ferrous ions to ferric ions to be 1:1.8, stop adding hydrogen peroxide;

[0036] (3) add sodium citrate, control the concentration of sodium citrate in the waste water to be 3g / L;

[0037] (4) Add sodium hydroxide, after the pH value of waste water is adjusted to 11, stop adding sodium hydroxide; Add sodium metasilicate afterwards, the addition of sodium metasilicate is 3g / L;

[0038] (5) Continue heating the solution obtained in step (4) to 70° C., keep it warm for 2 hours, and then cool it naturally to room temperature;

[0039] (6) After solid-liquid separation, the obtained solid powder i...

Embodiment 3

[0041] The method for preparing nano-scale ferroferric oxide by iron and steel pickling wastewater consists of the following steps:

[0042] (1) Filtrate the steel pickling wastewater to remove suspended solids in the wastewater, and heat to 50°C;

[0043] (2) Add hydrogen peroxide to oxidize part of the ferrous ions in the waste water into ferric ions, and control the molar ratio of ferrous ions to ferric ions to be 1:1.9, stop adding hydrogen peroxide;

[0044] (3) add sodium citrate, control the concentration of sodium citrate in the waste water to be 5g / L;

[0045] (4) Add sodium hydroxide, after the pH value of waste water is adjusted to 12, stop adding sodium hydroxide; Add sodium metasilicate afterwards, the addition of sodium metasilicate is 4g / L;

[0046] (5) Continue heating the solution obtained in step (4) to 80° C., keep it warm for 3 hours, and then cool it naturally to room temperature;

[0047] (6) After solid-liquid separation, the obtained solid powder is w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com