Sludge activated carbon with continuous pore size distribution and preparation method thereof

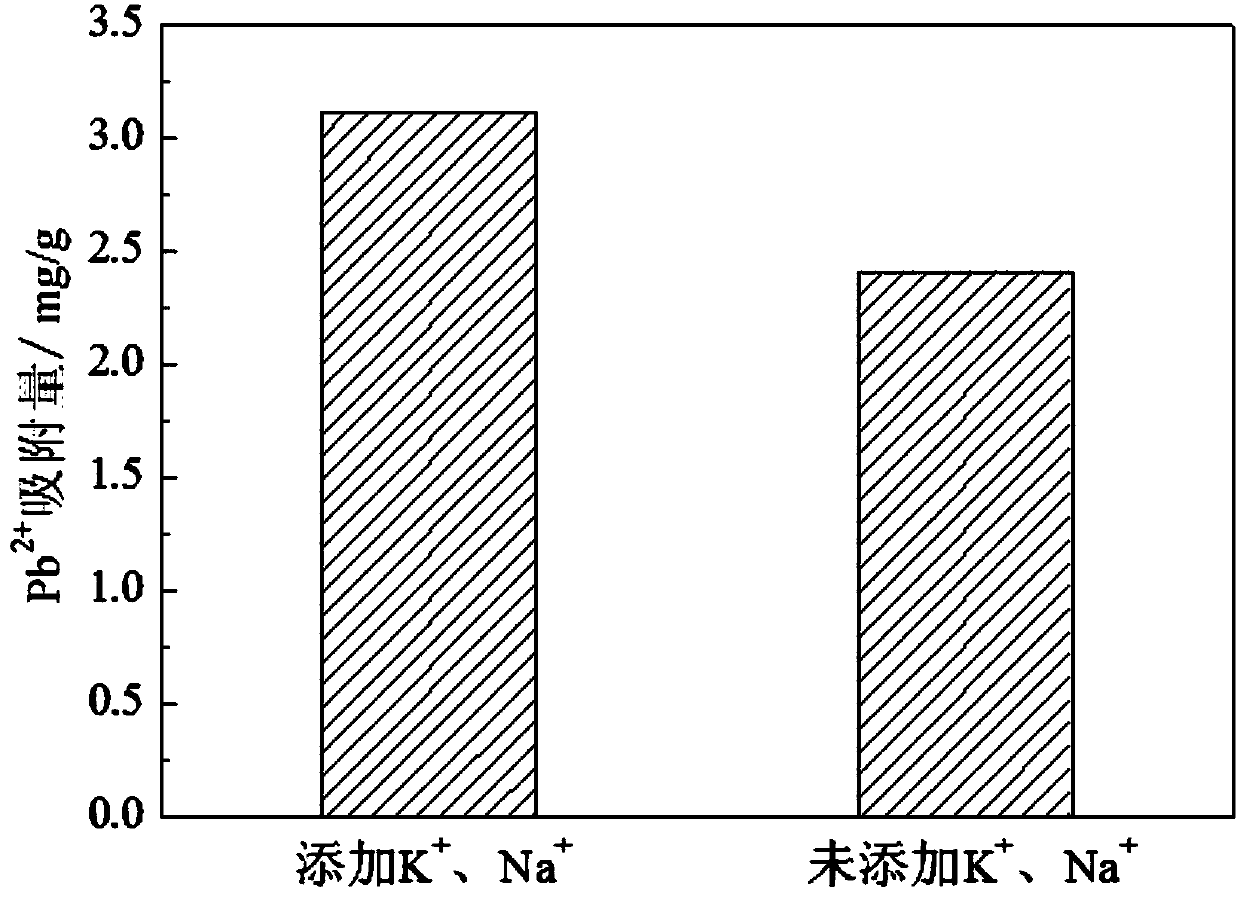

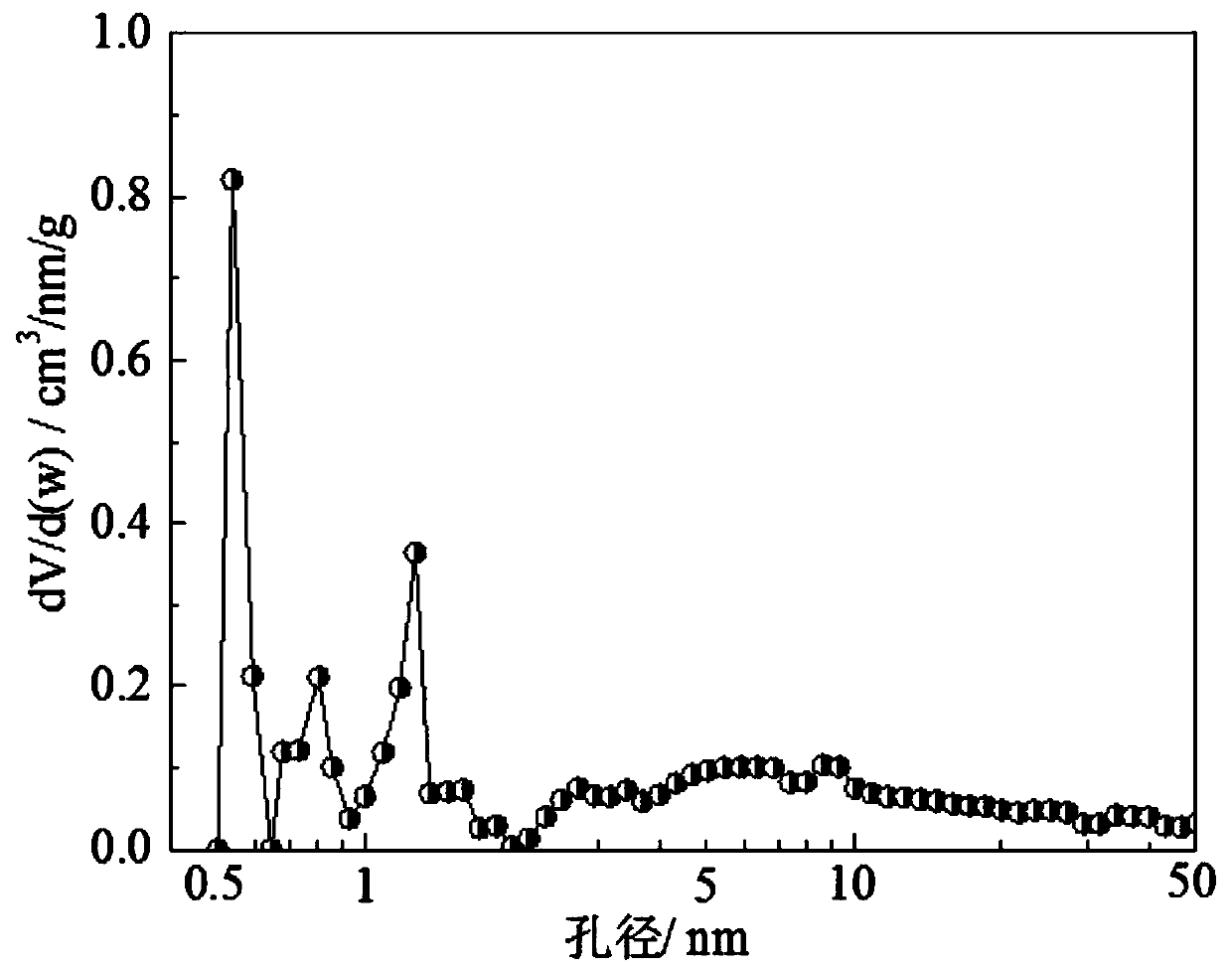

A sludge activated carbon and sewage treatment technology, applied in the field of environmental resource utilization, can solve the problems of lack of microporous structure, difficulty in achieving efficient adsorption of heavy metal ions and macromolecular pollutants, etc., to reduce preparation costs, promote pore development, and avoid carbon pollution. loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

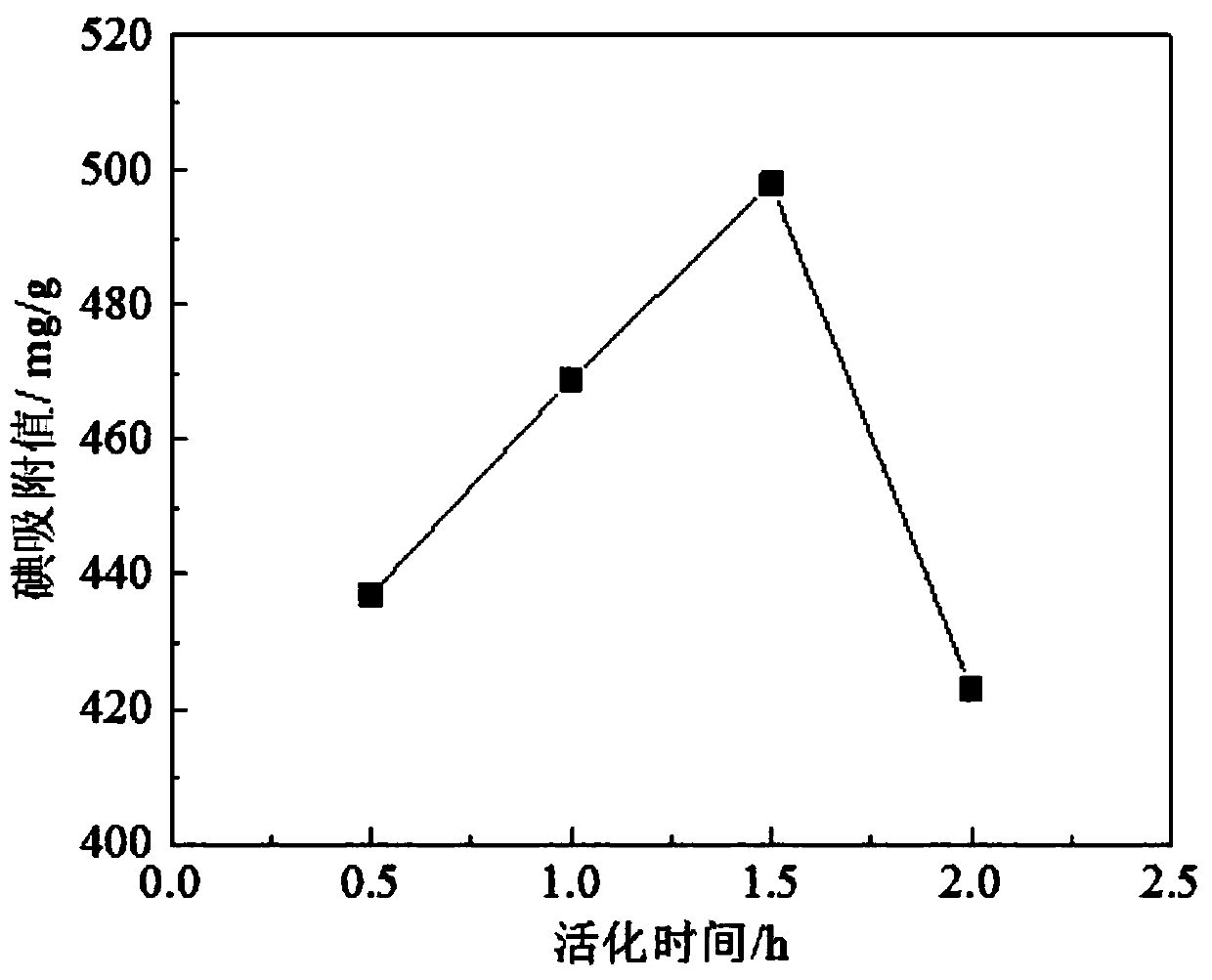

[0035] Immerse the sludge powder into the compound activator solution, the ratio of solid mass to solution volume is 1:2, and immerse at 20 degrees Celsius for 12 hours; the compound activator includes ZnCl 2 , phosphoric acid, K 2 S and NaCl, among which ZnCl 2 Concentration is 2mol / L, phosphoric acid concentration is 3mol / L, K 2 The addition amount of S is 10% of the dry sludge mass, and the NaCl addition amount is 1% of the dry sludge mass. Dry the mixture to a moisture content of 8%, add coal tar, the mass ratio of the mixture to coal tar is 1:0.3; granulate into a cylinder with a diameter of 8 mm and a length of 15 mm. Under the condition of nitrogen flow rate of 350ml / min, 35g of molding raw material was heated from room temperature of 20°C to 550°C at a rate of 10°C / min, and stayed for 1.5h. Then with a heating rate of 15°C / min, the temperature was raised to 800°C, and a mixed gas of water vapor and nitrogen was introduced simultaneously, the flow rate was 350ml / min,...

Embodiment 2

[0037] Immerse the sludge powder into the compound activator solution, the ratio of solid mass to solution volume is 1:2.5, and immerse at 20 degrees Celsius for 8 hours; the compound activator includes ZnCl 2 , phosphoric acid, K 2 S and NaCl, among which ZnCl 2 Concentration is 2.5mol / L, phosphoric acid concentration is 2mol / L, K 2 The addition amount of S is 15% of the dry sludge mass, and the NaCl addition amount is 2% of the dry sludge mass. Dry the mixture to a moisture content of 8%, add coal tar, the mass ratio of the mixture to coal tar is 1:0.35; granulate into a cylinder with a diameter of 8 mm and a length of 15 mm. Under the condition of nitrogen flow rate of 350ml / min, 52.5g of molding raw material was heated from room temperature of 25°C to 650°C at a rate of 15°C / min, and stayed for 1h. Then with a heating rate of 12° C. / min, the temperature is raised to 700° C., and a mixed gas of water vapor and nitrogen is introduced simultaneously, the flow rate is 350 m...

Embodiment 3

[0039] Immerse the sludge powder into the compound activator solution, the ratio of solid mass to solution volume is 1:2, and immerse at 20 degrees Celsius for 12 hours; the compound activator includes ZnCl 2 , phosphoric acid, K 2 S and NaCl, among which ZnCl 2 Concentration is 1mol / L, phosphoric acid concentration is 5mol / L, K 2 The addition amount of S is 8% of the dry sludge mass, and the NaCl addition amount is 0.5% of the dry sludge mass. Dry the mixture to a moisture content of 6%, add coal tar, the mass ratio of the mixture to coal tar is 1:0.2; granulate into a cylinder with a diameter of 8 mm and a length of 15 mm. Under the condition of nitrogen flow rate of 350ml / min, 40g of molding raw material was heated from room temperature of 20°C to 450°C at a rate of 8°C / min, and stayed for 2.5h. Then with a heating rate of 20° C. / min, the temperature is raised to 850° C., and a mixed gas of water vapor and nitrogen is introduced simultaneously, the flow rate is 350 ml / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com