Method for improving quality of micro-fine particle iron ore tailing return water

A technology for iron ore tailings and fine particles, which is applied in neutralization water/sewage treatment, flocculation/sedimentation water/sewage treatment, solid separation, etc. Full recovery and other issues to achieve the effect of reducing operating costs, improving the efficiency of mineral processing and sorting, and reducing the unit consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Taking the Yuanjiacun Iron Mine of Lan County Mining Industry as an example, a method for improving the backwater quality of fine-grained red-magnetic mixed iron ore tailings is provided.

[0026] Firstly, the distribution of the mine tailings is given:

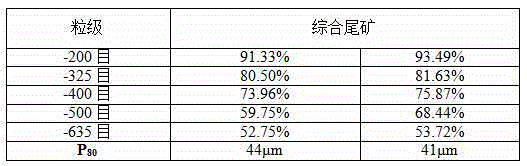

[0027] Table 1: Comprehensive tailings particle size distribution

[0028]

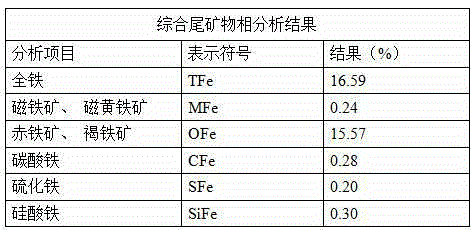

[0029] Table 2: Comprehensive tailings phase analysis

[0030]

[0031] The specific operation steps are:

[0032] (1) Lime mixing tanks and water tanks are added to the upstream of the tailings dam. After the arrival of the lime tanker, a certain amount of lime is transported into the mixing tank through an air pump, and water is added to the mixing tank by a centrifugal pump at the same time to prepare a concentration of 20%. milk of lime,

[0033] (2) After the preparation of lime milk is completed, according to the unit consumption control valve with an added amount of 600g / t, it will flow into the tailings pipeline automatically....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com