A Self-Driven Transient Stress Sensing Device

A sensing device and transient stress technology, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problems of low current output density, no self-driven transient pressure sensing device, etc., to improve the signal response strength , suitable for large-scale production, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

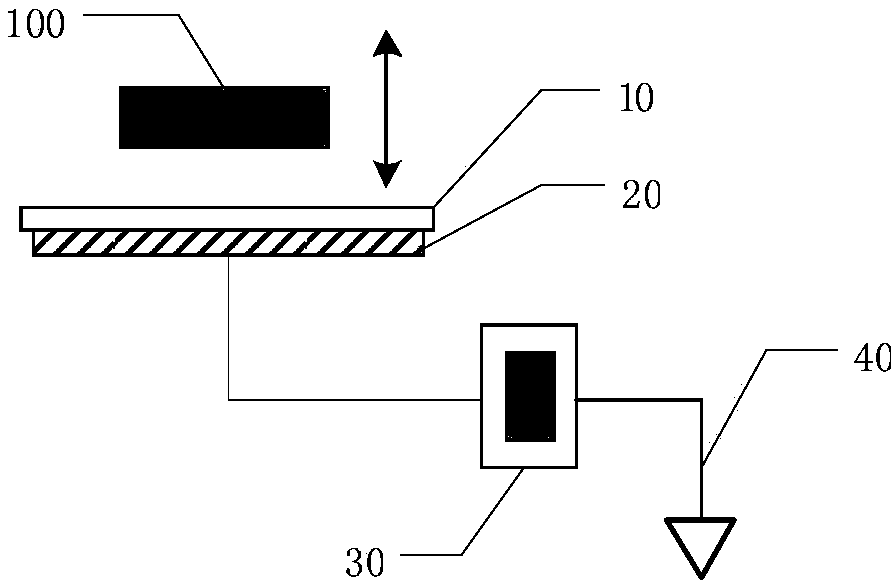

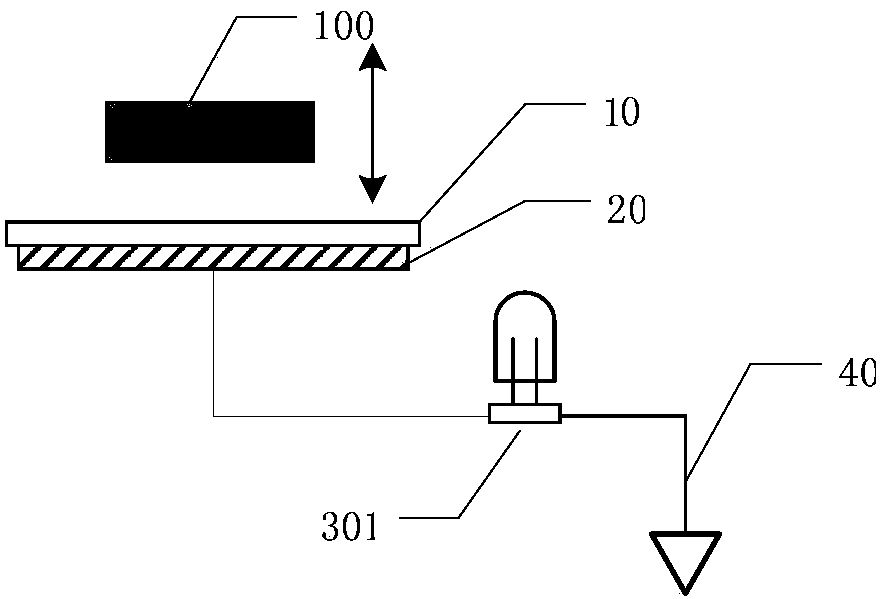

Method used

Image

Examples

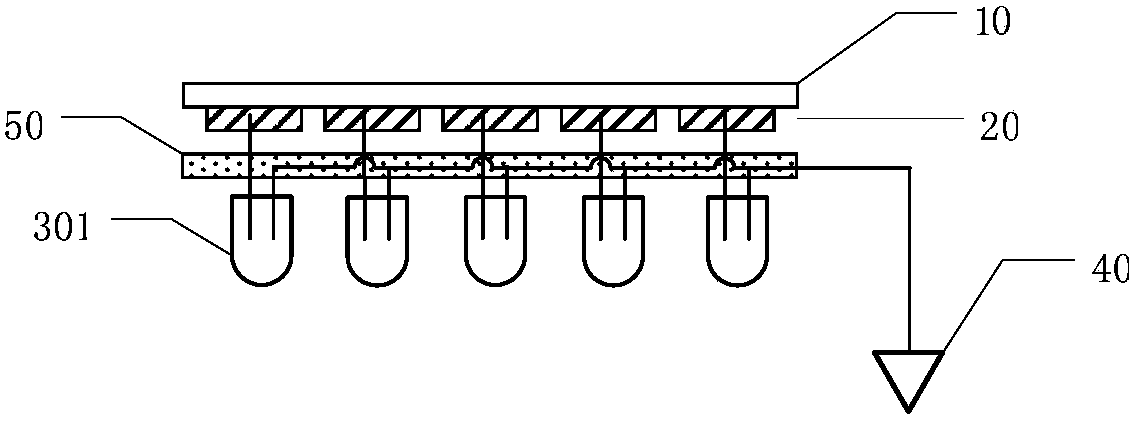

Embodiment 1

[0070] Cut 2 plastic plates of length 60mm x width 60mm x thickness 2mm to fix the LED array. First, insert the array of LEDs into the corresponding holes in a plastic plate, with the cathodes of all diodes connected together and connected to ground. Then insert the anode of the light-emitting diode array into another corresponding plastic plate below, and make an area of 10mm at the position of the anode 2 The electrode array, and then cover a layer of polyolefin material layer on the electrode, it is polarized by corona discharge, Figure 7 Schematic diagram of the fabricated sensor structure. When pressure is applied to a certain area of the polymer friction material layer, the corresponding LED of this area will emit light, and the stronger the light intensity, the greater the pressure. By analyzing the luminous intensity of the LED array, the transient pressure distribution applied on the device can be determined.

[0071] Figure 8 It is the change diagram of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com