Spherical silicon/carbon composite material for lithium ion battery as well as preparation method and application thereof

A technology of silicon-carbon composite materials and carbon composite materials, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of complex preparation process of silicon nanotubes, difficulty in industrialized large-scale production, and low degree of practicality. Achieve the effects of improving poor circulation, increasing tap density, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

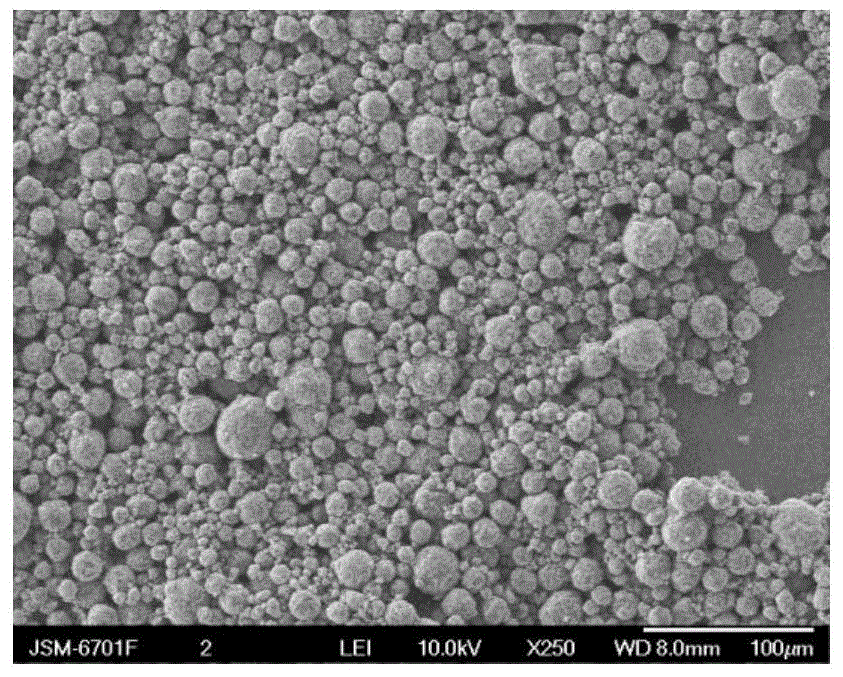

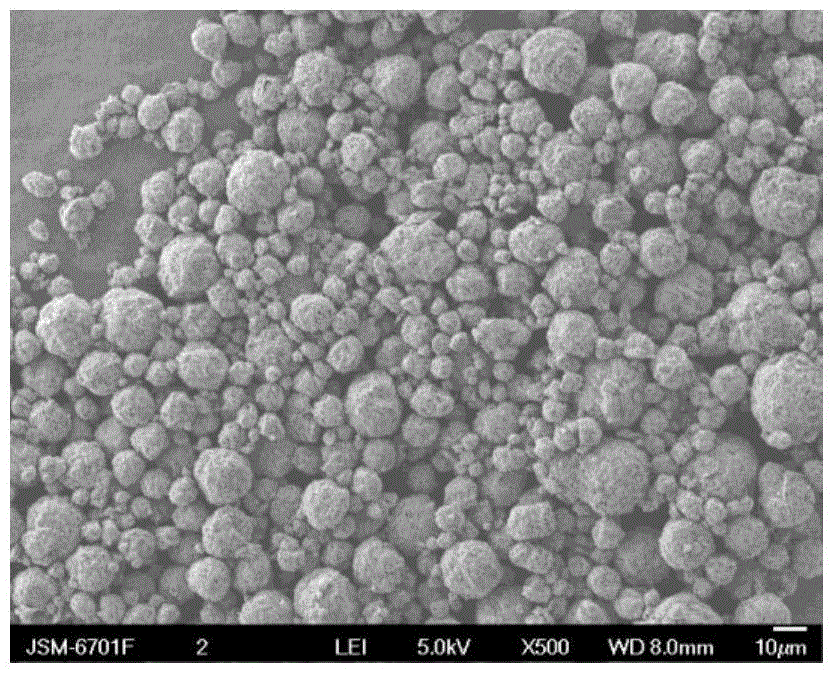

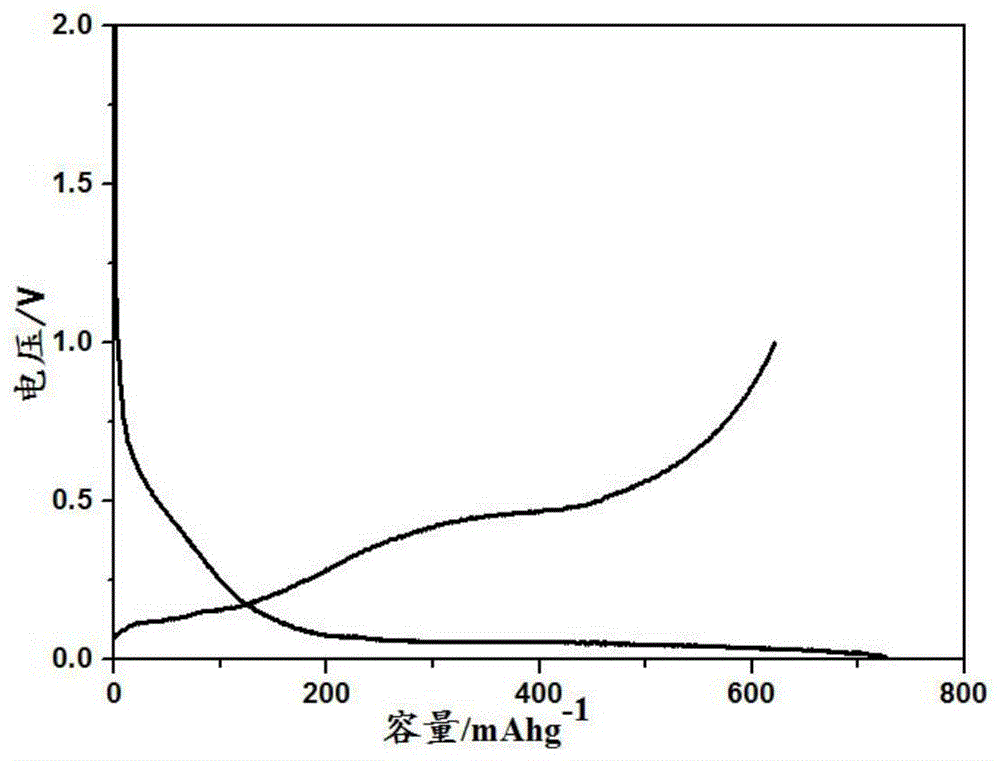

[0029] Embodiment 1, the preparation of silicon-carbon composite material and its electrochemical performance test:

[0030] After pulverizing the silicon powder by ball milling for 1 hour, sand milling for 5 hours, the obtained silicon powder of uniform size is mixed according to the mass ratio of silicon powder:graphite=4:6, with water as the solvent and PVP as the polymer additive, with a weight average molecular weight of 300000, sucrose is the hydroxyl dispersant, stirred at room temperature for more than 5h, and a slurry with a viscosity of 200mPa·s was obtained. The slurry was spray-dried, the inlet temperature was 180°C, and the outlet temperature was 100°C, and then the spray-dried sample was sintered at 600°C in a nitrogen atmosphere at a heating rate of 5°C / min for 2 hours to obtain a porous Silicon-carbon composite material, the silicon content in the porous carbon-silicon composite material is 35%, and the carbon content is 65%.

[0031] Soak the porous silicon-c...

Embodiment 2

[0038] Example 2: After the silicon powder is ball milled for 1 hour, sand milled for 5 hours, the obtained silicon powder of uniform size is mixed according to the mass ratio of silicon powder: graphite=4:6, with water as the solvent and PVP as the polymer additive. The weight-average molecular weight is 300,000, and sucrose is the hydroxyl dispersant. Stir at room temperature for more than 5 hours to obtain a slurry with a viscosity of 200 mPa·s. The slurry was spray-dried, the inlet temperature was 180°C, and the outlet temperature was 100°C, and then the spray-dried sample was sintered at 600°C in a helium atmosphere with a heating rate of 5°C / min for 6 hours to obtain a porous The silicon-carbon composite material, the silicon content in the porous carbon-silicon composite material is 35%, and the carbon content is 65%.

[0039] Soak the sintered porous silicon-carbon composite material sample in a solution of gelatin and conductive graphite, stir for more than 10 hours, ...

Embodiment 3

[0043] After pulverizing the silicon powder by ball milling for 1 hour, sand milling for 5 hours, the obtained silicon powder of uniform size is mixed according to the mass ratio of silicon powder:graphite=4:6, with water as the solvent and PVP as the polymer additive, with a weight average molecular weight of 300000, sucrose hydroxyl as dispersant, stirred at room temperature for more than 5h to obtain a slurry with a viscosity of 200mPa·s. The slurry was spray-dried, the inlet temperature was 180°C, and the outlet temperature was 100°C, and then the spray-dried sample was sintered at 600°C in an argon atmosphere at a heating rate of 10°C / min for 2 hours to obtain a porous The silicon-carbon composite material, the silicon content in the porous carbon-silicon composite material is 35%, and the carbon content is 65%.

[0044] Soak the porous silicon-carbon composite material sample obtained after sintering in a solution of gelatin, conductive graphite, and petroleum pitch, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com