Overlay construction method for repairing aged asphalt concrete seepage-prevention face plate

A technology of asphalt concrete and concrete slabs, applied in similar engineering fields, can solve problems affecting engineering repair effects, complex construction, dam body interference, etc., achieve good economy, save engineering quantity, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

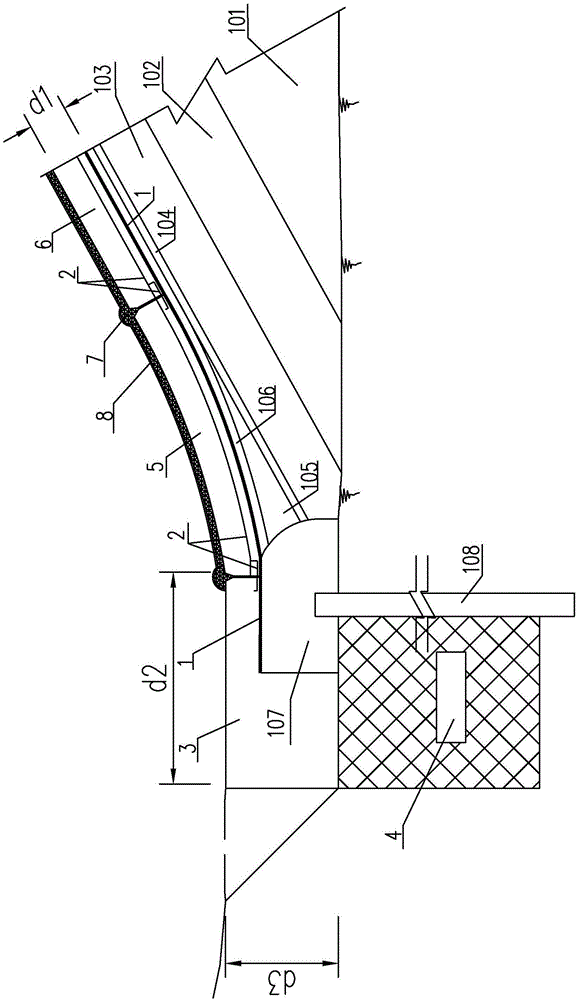

[0019] Such as figure 1 As shown, this embodiment is an overlay construction method for aging repair of asphalt concrete anti-seepage panels. The dam body has a rockfill body 101, a transition layer 102, and a cushion layer 103 in sequence from bottom to top, and has been settled for decades , the deformation is basically completed, a leveling cementation layer 104 is laid above the cushion layer 103, an old asphalt concrete panel 106 is laid on the upper part of the leveling cementation layer 104, and a bottom triangle is formed between the leveling cementation layer 104 and the old asphalt concrete panel 106 105, a concrete cover 107 is arranged at the front end of the triangular body, and an anti-seepage wall 108 is vertically arranged under the concrete cover; in this embodiment, glass fiber geogrid 1, copper Waterstop 2, new concrete panel 6, SR plastic filler 7 and anti-seepage protection cover sheet 8.

[0020] The specific implementation steps of this embodiment are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com