Preparation method of hexanitrohexaazaisowurtzitane and 2,5-dinitrotoluene eutectic explosive

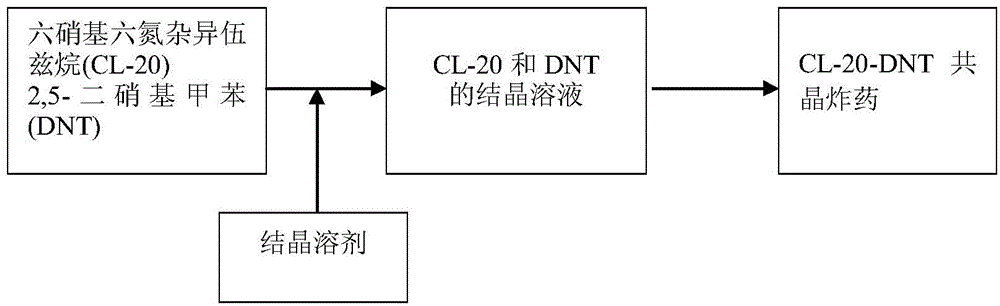

A technology of hexanitrohexaazane and isowurtzitane is applied in the field of preparation of hexanitrohexaazaisowurtzitane and 2,5-dinitrotoluene eutectic explosive, and can solve the problems of low melting point, density and energy, There are no problems such as public literature reports and safety defects, and the effects of reducing sensitivity, convenient operation and increasing melting point are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

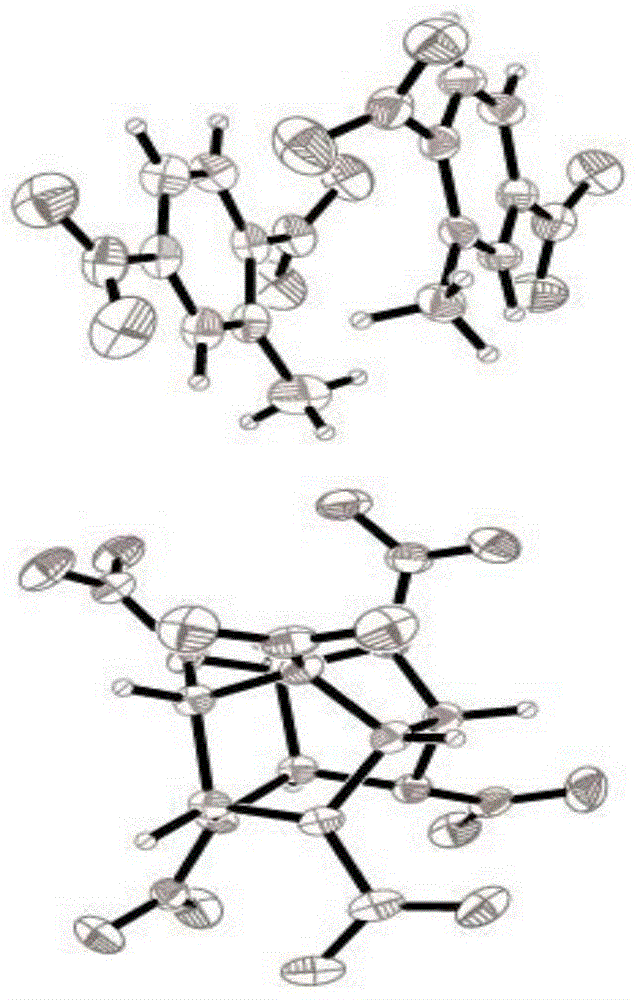

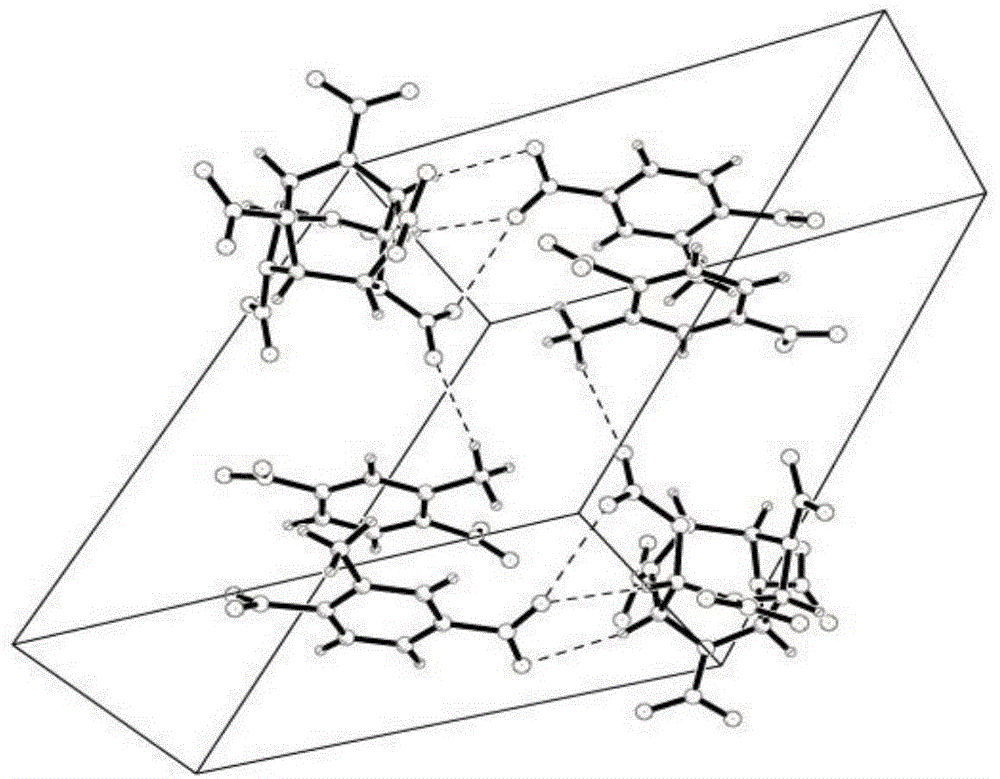

[0015] Weigh 1 mmol of CL-20 and 2 mmol of 2,5-DNT in a weighing bottle, add 5 mL of ethyl acetate at room temperature, and ultrasonically shake the mixture until the solids are completely dissolved to obtain a saturated mixture of CL-20 and 2,5-DNT. crystallization solution. After the sealing film is sealed, puncture 8 small holes with a pin, and let it stand at room temperature for 3 days. The solvent ethyl acetate volatilizes, and pale yellow transparent crystal particles are precipitated. After filtering, washing and drying, CL-20 / 2,5-DNT eutectic explosive crystals are obtained. . Crystals with excellent morphology were selected for single crystal X-ray diffraction crystal structure analysis, and figure 2 The molecular structure ellipsoid diagram and image 3 The crystal structure stacking diagram shown shows that there is one CL-20 molecule and two DNT molecules in a single lattice, and a dense crystal structure is formed, and the nitro oxygen atom of CL-20 and the hy...

Embodiment 2

[0017] Weigh 1 mmol of CL-20 and 2 mmol of 2,5-DNT in a weighing bottle, add 5 mL of acetone at room temperature, and ultrasonically shake the mixture until the solids are completely dissolved to obtain a mixed saturated crystallization solution of CL-20 and 2,5-DNT . After sealing with a parafilm, make some small holes, let it stand at room temperature for 3 days, the solvent acetone volatilizes, and a light yellow transparent block crystal is precipitated. After filtering, washing and drying, the eutectic explosive of CL-20 and 2,5-DNT is obtained. The crystal was detected by infrared spectroscopy, and the absorption spectrum obtained was compared with that of elemental CL-20 and 2,5-DNT. Figure 5 shown. Analyze the attribution of the main absorption peaks, the most characteristic one is in the C-H stretching vibration region around 3000cm-1, the eutectic molecule shows two absorption peaks at 3033cm-1 and 3107cm-1, which belong to the C-H stretching vibration spectrum of ...

Embodiment 3

[0019] Weigh 1 mmol of CL-20 and 2 mmol of 2,5-DNT in a weighing bottle, add 20 mL of methanol at room temperature, and ultrasonically shake the mixture until all solids are dissolved to obtain a mixed saturated crystallization solution of CL-20 and 2,5-DNT . After sealing with a parafilm, make 8 small holes, let the solvent methanol volatilize at room temperature, and crystals are precipitated. After filtering, washing and drying, the eutectic explosive of CL-20 / 2,5-DNT is obtained. Differential scanning calorimetry (DSC) was performed on the obtained eutectic, and compared with the DSC curves of elemental CL-20 and 2,5-DNT such as Image 6 Show. The melting point of CL-20 / 2,5-DNT eutectic explosive is 122.6°C, which is significantly higher than the 72.4°C of DNT, which proves that the thermal stability has been significantly improved; the thermal decomposition temperature is 215.8°C, which is higher than that of CL- The temperature of 20 at 250.0℃ has decreased significant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com