Process and equipment for nature freezing desalting of high salt water

A high-salt and high-salt wastewater technology, applied in the field of desalination water technology and equipment, can solve the problems of low desalination rate, high environmental risk, unbearable for enterprises, etc., achieve simple process route, solve secondary pollution, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

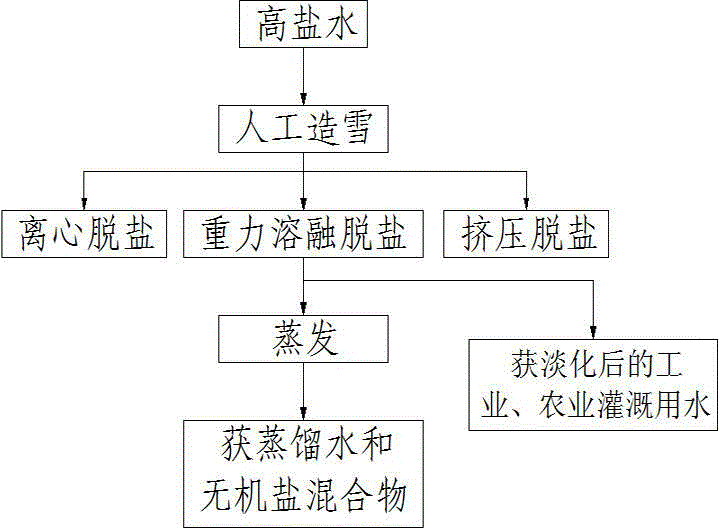

[0036] Such as figure 1 Shown, a kind of technology of natural freezing and desalinating high brine, its processing steps are:

[0037] 1) Water storage and cooling: the outlet temperature of high-salt wastewater with a TDS of about 10,000mg / L is 18°C-30°C, and the pH value is 7.5-8.0. First, the industrial high-salt wastewater is discharged into the storage tank for storage and used Heat exchange is performed in winter when the temperature is low to reduce the temperature of industrial high-salt wastewater, which is beneficial to the efficiency of artificial snowmaking.

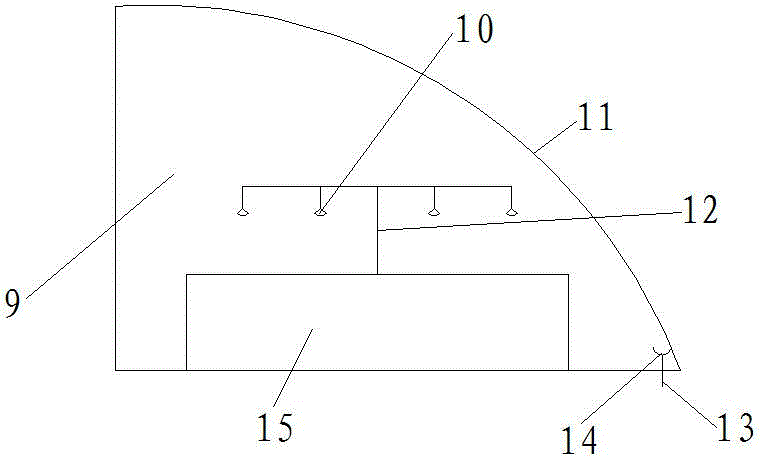

[0038] 2) Artificial snowmaking: After the natural environment temperature is lower than -1°C, use snowmaking equipment to pump out the industrial high-salt wastewater in the storage tank for artificial snowmaking, and pile the artificial snow on a 1% slope. On the snow field, the thickness of artificial snow is 0.5-0.9 meters; the surface of the snow field needs to be waterproofed to prevent high salt wate...

Embodiment 2—5

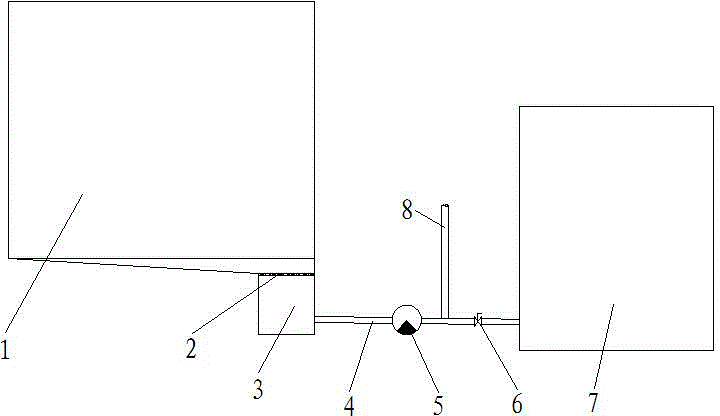

[0047] On the basis of above-mentioned embodiment 1, as figure 2 As shown, step 2) artificial snow is placed in the snow storage tank 1 in the snow storage device for natural freezing and desalination of high salt water, and the inner surface of the snow storage tank is treated with anti-seepage to prevent groundwater pollution from high salt water seepage. The bottom of the snow storage pool is a slope, and a water storage well 3 is arranged at the lowest point of the slope. The water storage well communicates with the high salt water storage tank 7 and the water supply pipeline 8 through a pipeline 4, and a valve 6 and a water pump 5 are installed on the pipeline 4. The valve is The solenoid valve is connected with the electrical control device. A perforated cover plate 2 is installed on the water storage well to prevent snow from pouring into the water storage well. A water quality detection sensor is installed on the pipeline connecting the water storage well and the hig...

Embodiment 6

[0052] A process for naturally freezing and desalinating high-salt water, the process steps of which are:

[0053] 1) Water storage and cooling: the TDS of industrial high-salt wastewater is about 20,000mg / L, the pH value is 7.8-8.5, and the outlet temperature of high-salt wastewater is about 18°C. First, the industrial high-salt wastewater is discharged into the storage tank for storage , and use the lower temperature in winter for heat exchange to reduce the temperature of industrial high-salt wastewater, which is conducive to the efficiency of artificial snowmaking.

[0054] 2) Artificial snowmaking: After the natural environment temperature is lower than -2°C, use snowmaking equipment to pump out the industrial high-salt wastewater in the storage tank for artificial snowmaking, and pile the artificial snow on a slope with a slope of about 5%. On the snowmaking field, the thickness of the artificial snow is about 6 meters; the surface of the snowmaking field needs to be wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com