A method for preparing nitrogen-doped graphene by combustion synthesis

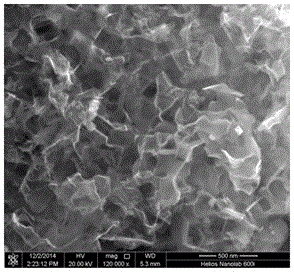

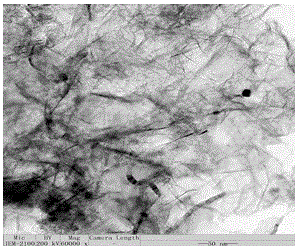

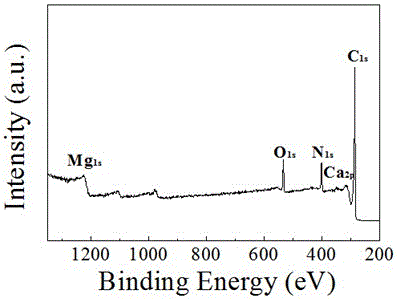

A nitrogen-doped graphene, combustion synthesis technology, applied in the field of carbon materials, can solve the problems of low nitrogen content and high equipment requirements, and achieve the effect of complete sheet structure, large effective specific surface area and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0042] Specific implementation mode one: this implementation mode is realized through the following steps:

[0043] (1) Weigh 26.7% of magnesium powder, 60% of calcium carbonate and 13.3% of urea by mass percentage; wherein, the purity of the magnesium powder is 99.5%, and the average particle diameter is 0.1mm; the purity of calcium carbonate is 99% %, the average particle diameter is 0.044mm, and the purity of urea is 99%;

[0044] (2) Evenly mix the magnesium powder, calcium carbonate and urea powder weighed in step (1) to obtain a mixed powder;

[0045] (3) Put the mixed powder obtained in step (2) into a 1L crucible, and add the igniter Fe above the mixed powder 3 o 4 +Mg;

[0046] (4) Then put the crucible into a 20L combustion synthesis reaction device;

[0047] (5) Introduce carbon dioxide into the combustion synthesis reaction device to fill the crucible and the combustion synthesis reaction device with carbon dioxide;

[0048] (6) By means of partial electrotherma...

specific Embodiment approach 2

[0051] Specific implementation mode two: this implementation mode is realized through the following steps:

[0052] (1) Weigh 25.1% magnesium powder, 67.3% magnesium carbonate powder and 7.6% ammonium chloride by mass percentage; wherein, the purity of the magnesium powder is 99.5%, and the average particle diameter is 0.1mm; the calcium carbonate The purity is 99%, the average particle diameter is 0.044mm, and the purity of ammonium chloride is 99%;

[0053] (2) Evenly mix the magnesium powder, calcium carbonate and ammonium chloride powder weighed in step (1) to obtain a mixed powder;

[0054] (3) Put the mixed powder obtained in step (2) into a 1L crucible, and add the igniter Fe above the mixed powder 3 o 4 + Al;

[0055] (4) Then put the crucible into a 20L combustion synthesis reaction device;

[0056] (5) Introduce carbon dioxide into the combustion synthesis reaction device to fill the crucible and the combustion synthesis reaction device with carbon dioxide;

[0...

specific Embodiment approach 3

[0060] Specific implementation mode three: this implementation mode is realized through the following steps:

[0061] (1) Weigh 27.6% of magnesium powder, 36.2% of calcium carbonate, 22.3% of magnesium carbonate, 6.8% of ammonium carbonate and 7.1% of ammonium sulfite by mass percentage; wherein, the purity of the magnesium powder is 99.5% , the average particle diameter is 0.1mm; the purity of calcium carbonate is 99%, the average particle diameter is 0.044mm, the purity of ammonium carbonate is 99%, and the purity of ammonium sulfite is 99%;

[0062] (2) Evenly mix the magnesium powder, calcium carbonate, magnesium carbonate, ammonium carbonate and ammonium sulfite powder weighed in step (1) to obtain a mixed powder;

[0063] (3) Put the mixed powder obtained in step (2) into a 1L crucible, and add the igniter Fe above the mixed powder 3 o 4 +Mg;

[0064] (4) Then put the crucible into a 20L combustion synthesis reaction device;

[0065] (5) Introduce carbon dioxide into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com