Method for preparing magnesium ammonium phosphate and magnesium ammonium nitrate with phosphate tailings

A technology of magnesium ammonium phosphate and magnesium ammonium nitrate, applied in chemical instruments and methods, phosphorus compounds, magnesium compounds, etc., can solve problems that threaten human and animal safety, land degradation, and vegetation destruction, and achieve good fertilizer efficiency, rich nutrient element content, The effect of increasing phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for preparing magnesium ammonium phosphate and magnesium ammonium nitrate from phosphorus tailings, comprising the following steps:

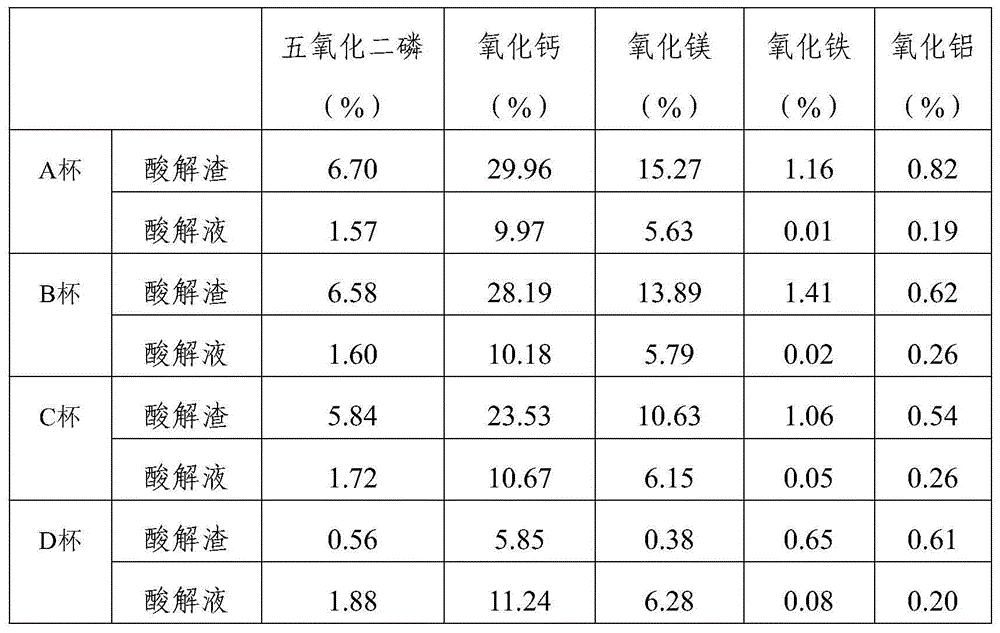

[0060] (1) Acid hydrolysis: first add nitric acid into the reaction tank, adjust the temperature to 50°C, keep the constant temperature, and adjust the speed to 200r / min, then add phosphorus tailings, and then increase the speed to 10r / min. 450r / min, ammonia water is used to absorb the carbon dioxide gas generated by the reaction to obtain ammonium carbonate solution, the mass ratio of nitric acid and phosphorus tailings is 2:1, and after 1 hour of reaction, the reaction material liquid is obtained;

[0061] (2) Filtration and washing: filter the reaction feed liquid to obtain acidolysis solution and acidolysis residue, wash the acidolysis residue to obtain residue and lotion, and return the lotion to the acidolysis process;

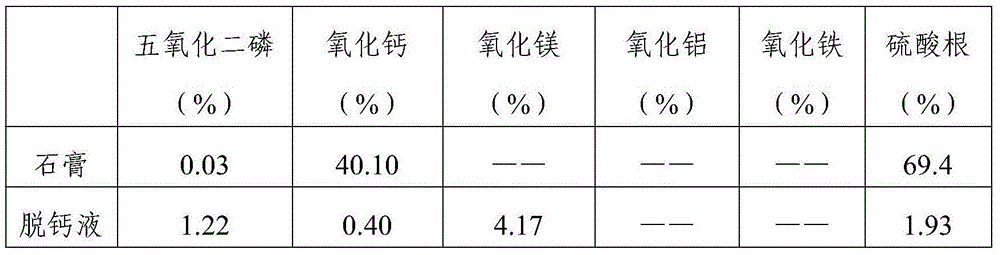

[0062] (3) Decalcification: first preheat the acidolysis solution to a temperature of 50°C, adjust the r...

Embodiment 2

[0070] A method for preparing magnesium ammonium phosphate and magnesium ammonium nitrate from phosphorus tailings, comprising the following steps:

[0071] (1) Acid hydrolysis: first add nitric acid into the reaction tank, adjust the temperature to 60°C, keep the constant temperature, and adjust the speed to 300r / min, add phosphorus tailings, and then increase the speed to 20r / min. 550r / min, ammonia water is used to absorb the carbon dioxide gas generated by the reaction to obtain ammonium carbonate solution, the mass ratio of nitric acid and phosphorus tailings is 3:1, and after 3 hours of reaction, the reaction feed liquid is obtained;

[0072] (2) Filtration and washing: filter the reaction feed liquid to obtain acidolysis solution and acidolysis residue, wash the acidolysis residue to obtain residue and lotion, and return the lotion to the acidolysis process;

[0073] (3) Decalcification: first preheat the acidolysis solution to a temperature of 60°C, adjust the rotating ...

Embodiment 3

[0081] A method for preparing magnesium ammonium phosphate and magnesium ammonium nitrate from phosphorus tailings, comprising the following steps:

[0082] (1) Acid hydrolysis: first add nitric acid into the reaction tank, adjust the temperature to 55°C, keep the constant temperature, and adjust the speed to 250r / min, then add phosphorus tailings, and then increase the speed to 15r / min. 500r / min, using ammonia water to absorb the carbon dioxide gas generated by the reaction, to obtain ammonium carbonate solution, the mass ratio of nitric acid and phosphorus tailings is 2.5:1, after 2 hours of reaction, the reaction material liquid is obtained;

[0083] (2) Filtration and washing: filter the reaction feed liquid to obtain acidolysis solution and acidolysis residue, wash the acidolysis residue to obtain residue and lotion, and return the lotion to the acidolysis process;

[0084](3) Decalcification: first preheat the acid solution to a temperature of 55°C, adjust the speed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com