A Synthesis Method of Cable Type Silver Chloride Coated Copper Nanostructure

A nanostructure, silver chloride technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of high cost, slow preparation process, etc., achieve uniform heating, easy control, and product Simple and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

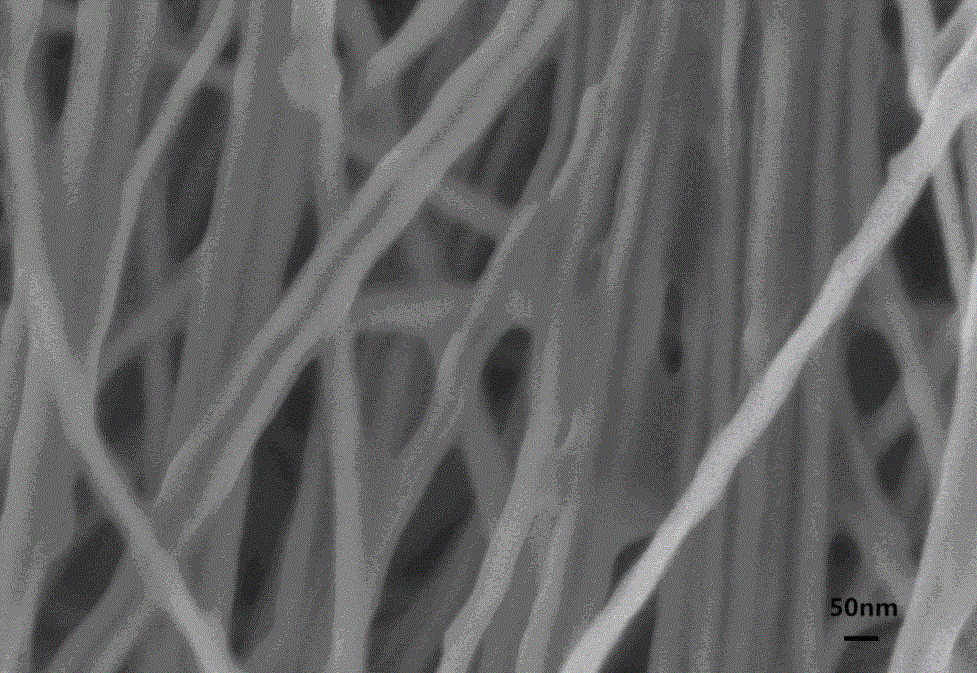

Embodiment 1

[0040] The first step: weigh 0.16g dodecyltrimethylammonium chloride (DTAC) and 0.086g AgNO respectively 3 Place them in 25ml reaction flasks labeled B and C respectively, add 5ml deionized water and magnetons to dissolve, and dissolve the AgNO 3 The solution was added dropwise into the DTAC solution, and magnetically stirred for 30 min to obtain a milky white solution. Weigh 0.0220g CuCl respectively 2 • 2H 2 O, 0.1846g hexadecylamine (HAD), and 0.0754g glucose were placed in a 25ml reaction bottle labeled A, added 10ml deionized water and a magnet, and magnetically stirred at room temperature for 12h until it dissolved into a blue solution.

[0041] Step 2: Fix the blue solution on the iron stand, place it in the oil bath, turn on the switch of the oil bath, set the temperature to 110°C, and turn on the magnetic stirring.

[0042] Step 3: Wait for the oil bath to reach the set temperature and stabilize, then magnetically stir for 6 hours, and the solution turns brick red....

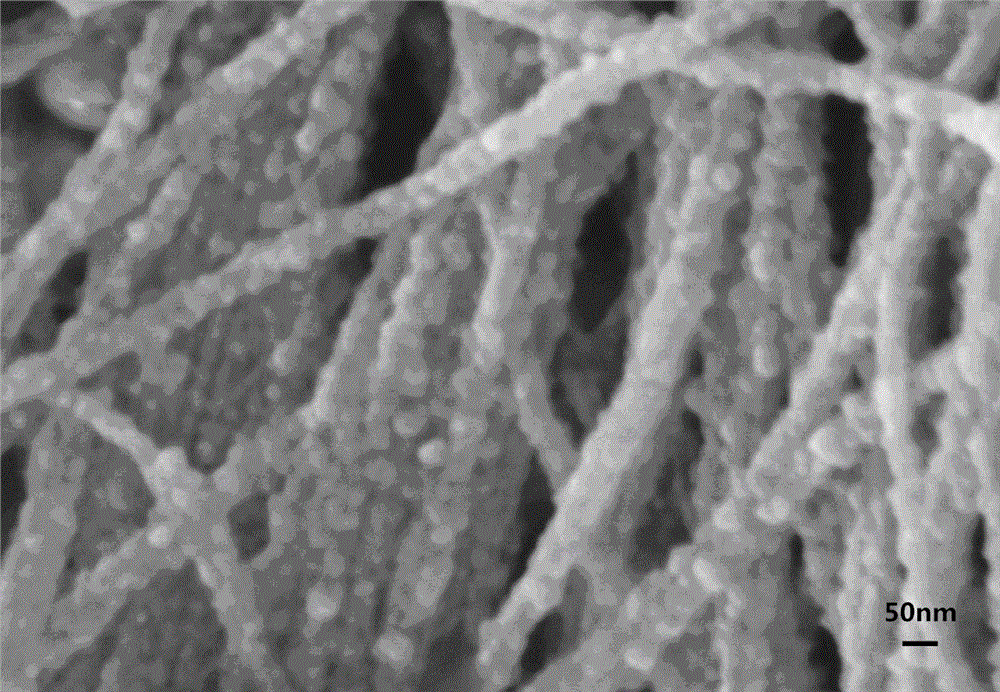

Embodiment 2

[0047] The first step: weigh 0.16g dodecyltrimethylammonium chloride (DTAC) and 0.086g AgNO respectively 3 Place them in 25ml reaction flasks labeled B and C respectively, add 5ml deionized water and magnetons to dissolve, and dissolve the AgNO 3 The solution was added dropwise into the DTAC solution, and magnetically stirred for 30 min to obtain a milky white solution. Weigh 0.0880g CuCl respectively 2 • 2H 2 O, 0.7384g hexadecylamine (HAD), and 0.3016g glucose were placed in a 25ml reaction bottle labeled A, added 10ml deionized water and a magnet, and magnetically stirred at room temperature for 12h until it dissolved into a blue solution.

[0048] Step 2: Fix the blue solution on the iron stand, place it in the oil bath, turn on the switch of the oil bath, set the temperature to 110°C, and turn on the magnetic stirring.

[0049] Step 3: Wait for the oil bath to reach the set temperature and stabilize, then magnetically stir for 6 hours, and the solution turns brick red....

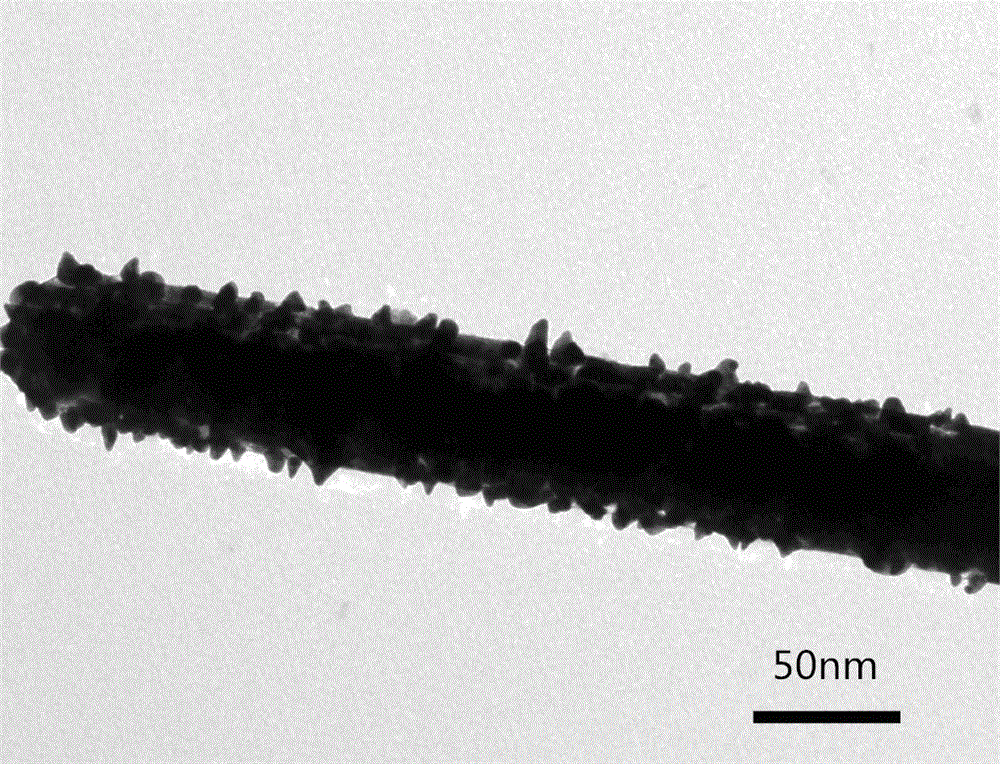

Embodiment 3

[0054] The first step: weigh 0.16g dodecyltrimethylammonium chloride (DTAC) and 0.086g AgNO respectively 3 Place them in 25ml reaction flasks labeled B and C respectively, add 5ml deionized water and magnetons to dissolve, and dissolve the AgNO 3 The solution was added dropwise into the DTAC solution, and magnetically stirred for 30 min to obtain a milky white solution. Weigh 0.440g CuCl respectively 2 • 2H 2 O, 3.692g hexadecylamine (HAD), and 1.508g glucose were placed in a 25ml reaction bottle labeled A, and 10ml deionized water and magnetons were added, and magnetically stirred at room temperature for 12h until it dissolved into a blue solution.

[0055] Step 2: Fix the blue solution on the iron stand, place it in the oil bath, turn on the switch of the oil bath, set the temperature to 110°C, and turn on the magnetic stirring.

[0056] Step 3: Wait for the oil bath to reach the set temperature and stabilize, then magnetically stir for 6 hours, and the solution turns bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com