A preparing method of a double-light-emitting transition metal ion doped semiconductor quantum dot

A technology of transition metal ions and semiconductors, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high toxicity of quantum dot materials, small Stokes shift, low fluorescence quantum yield, etc., and achieve simple preparation methods, The effect of large Stokes shift and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a method for preparing dual light emitting transition metal ion doped semiconductor quantum dots, the method comprising:

[0026] Step 1: Mix acetate, sulfur powder and oil phase solvent to obtain a mixed solution;

[0027] Step 2: In an inert atmosphere, heat the mixed solution obtained in Step 1 to 200-260°C at a rate of 10-30°C / min, and maintain this temperature for 10 to 120 minutes to form a mixed liquid crystal core;

[0028] Step 3: Lower the reaction temperature to 100-150°C, then add the zinc precursor solution to the mixed liquid crystal core obtained in step 2, and heat it to 220-280°C at a rate of 10-30°C / min, and maintain this temperature 10~120min to form a mixture of zinc sulfide shell;

[0029] Step 4: The reaction temperature is lowered to 60-100° C., and then the solvent is added to the zinc sulfide shell mixture obtained in Step 3 to obtain dual light emitting transition metal ion-doped semiconductor quantum dots.

[0030] Accord...

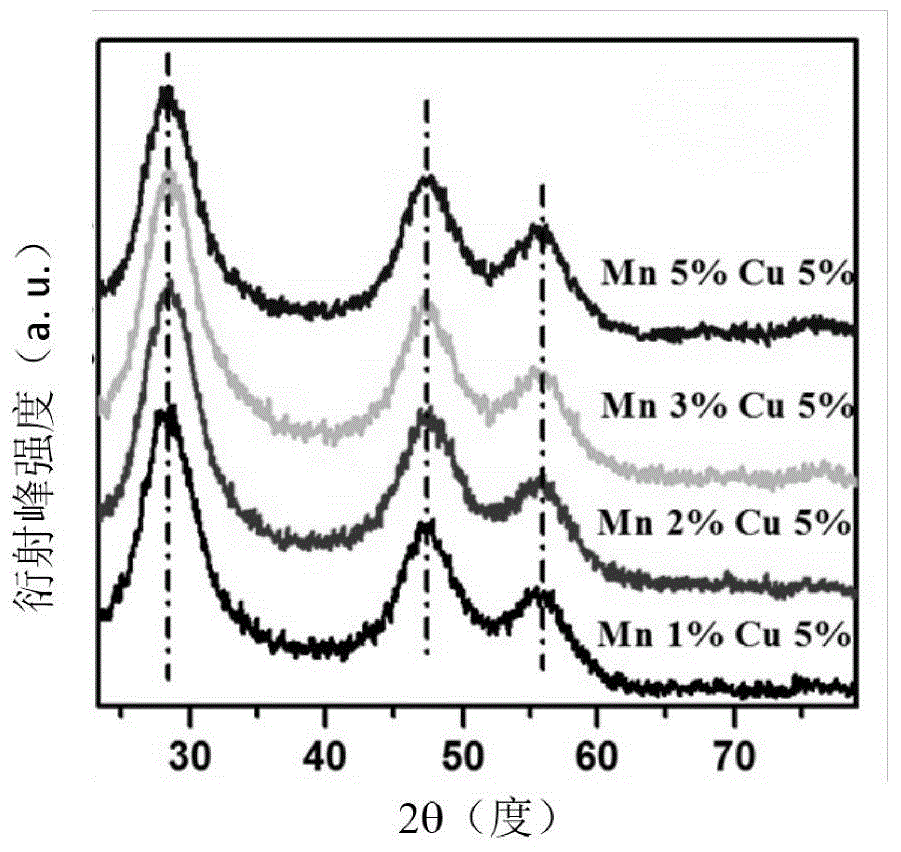

Embodiment 1

[0036] Step 1: Add 0.02mmol copper acetate, 0.008mmol manganese acetate, 0.2mmol zinc acetate, 0.2mmol indium acetate, 0.8mmol sulfur powder, 4.0ml n-dodecanethiol and 6.0mL oleylamine to 50mL three In the neck flask, get the mixed solution;

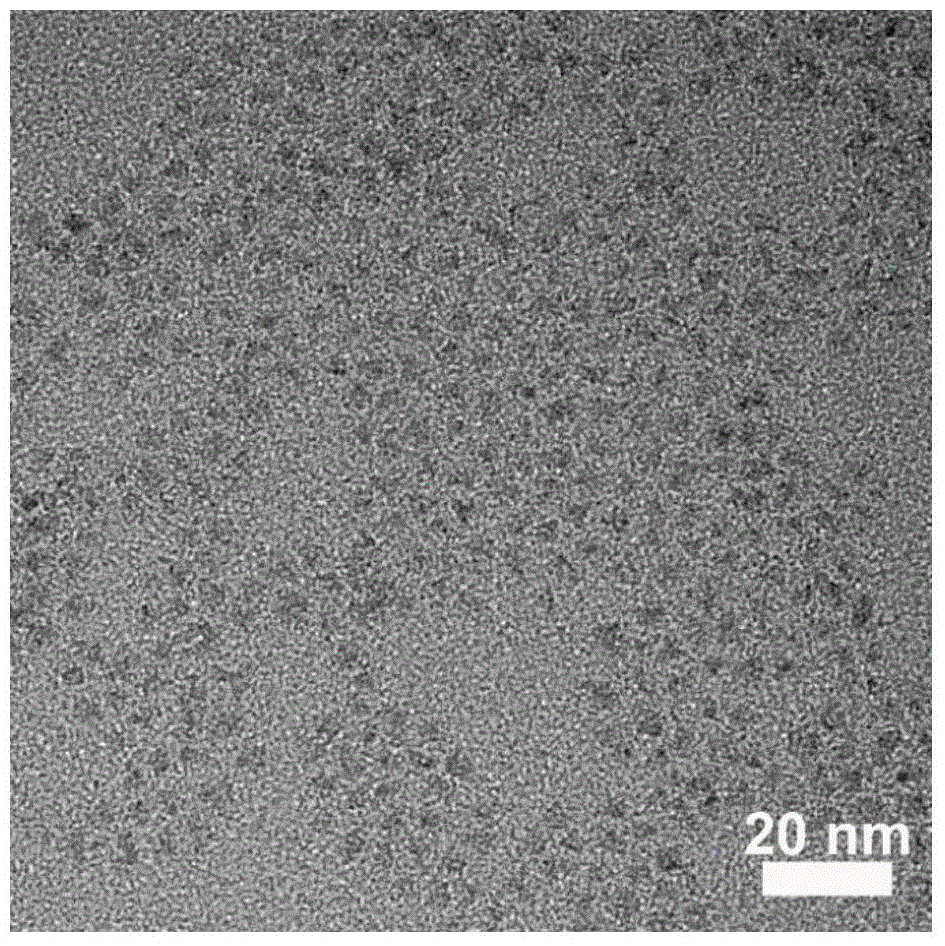

[0037] Step 2: Vacuum multiple times and pass in inert gas to remove gas. Under the protection of argon, heat the mixed solution obtained in step 1 to 220°C at a rate of 15°C / min, and keep this temperature for 10 minutes to form Copper and manganese doped zinc, indium and sulfur crystal nuclei;

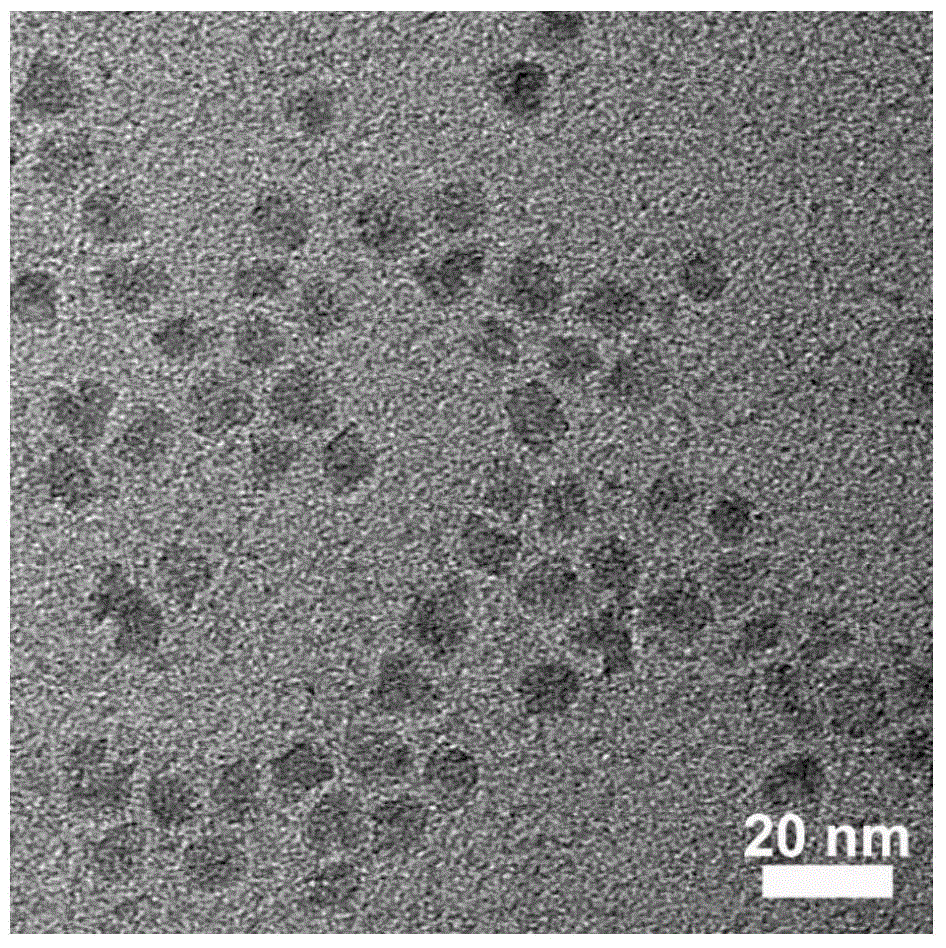

[0038] Step 3: Lower the reaction temperature to 100°C, mix 0.4mmol zinc acetate in 0.1mL oleylamine and 0.9mL octadecene into a zinc precursor solution, and then add the zinc precursor solution to the copper and manganese obtained in step 2. Doped with zinc, indium and sulfur crystal nuclei, heated to 240°C at a rate of 15°C / min, and maintained at this temperature for 20 minutes to form a zinc sulfide shell mixture;

[0039] Step 4: Add 10mL of tolu...

Embodiment 2

[0043] Step 1: Add 0.02mmol copper acetate, 0.008mmol manganese acetate, 0.2mmol zinc acetate, 0.2mmol indium acetate, 0.8mmol sulfur powder, and 10mL octadecenamine into a 50mL three-necked flask at room temperature to obtain a mixed solution ;

[0044] Step 2: Vacuum several times and pass in inert gas to remove gas. Under the protection of argon, heat the mixed solution obtained in step 1 to 200°C at a rate of 10°C / min, and keep this temperature for 20 minutes to form Copper and manganese doped zinc, indium and sulfur crystal nuclei;

[0045] Step 3: Lower the reaction temperature to 120°C, mix 0.4mmol zinc acetate in 0.1mL oleylamine and 0.9mL octadecene to form a zinc precursor solution, and then add the zinc precursor solution to the copper and manganese obtained in step 2. Doped with zinc, indium and sulfur crystal nuclei, heated to 220°C at a rate of 10°C / min, and maintained at this temperature for 10 minutes to form a zinc sulfide shell mixture;

[0046] Step 4: Add 10 mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com