Space environment damage prevention protective coating as well as preparation method and application thereof

A protective coating and space environment technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as surface cracking, and achieve the effect of not easy to crack, low cost, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

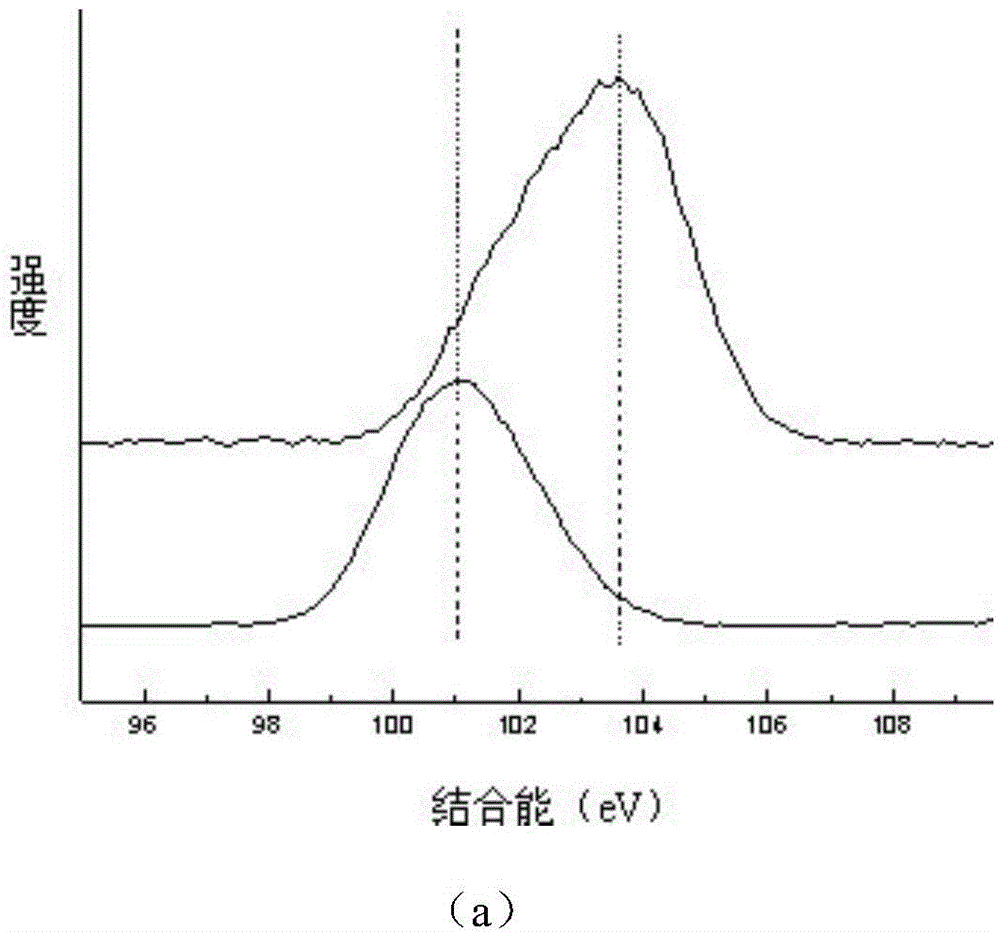

Method used

Image

Examples

Embodiment 1

[0030] First repeat the vacuum-pumping-nitrogen-filling operation of the reactor 3 to 5 times, then fill the entire reaction system with nitrogen at a rate of 1-10mL / s, open the nitrogen purge valve of the reactor, and make the nitrogen automatically overflow the reactor , to prevent air from entering; the tetrahydrofuran after dewatering was added to the above-mentioned reactor cooled with an ice-water bath, followed by methylvinyldichlorosilane, and then slowly passed NH at a flow rate of 50mL / min 3 , continuously stirred for 6 hours, then filtered and distilled under reduced pressure to obtain a colorless, viscous, colloidal polysilazane precursor; the polysilazane precursor was dissolved in tetrahydrofuran or toluene, according to Si / Al moles Add aluminum isopropoxide in a ratio of 1:1, keep stirring at 150°C for 5 hours, filter and distill under reduced pressure to obtain a light yellow viscous liquid, that is, polyaluminosilazane polymer; polyaluminum is treated with tolu...

Embodiment 2

[0036] First, repeat the operation of vacuum-pumping and nitrogen-filling the reactor for 3 to 5 times; then fill the entire reaction system with nitrogen at a rate of 1-10mL / s, and open the nitrogen vent valve of the reactor, so that the nitrogen automatically overflows the reactor , to prevent air from entering; the tetrahydrofuran after dewatering was added to the above-mentioned reactor cooled with an ice-water bath, followed by a mixture of methyldichlorosilane and methylvinyldichlorosilane, and then slowly passed through at a flow rate of 40mL / min into NH 3 , stirred continuously for 10 hours, then filtered and distilled under reduced pressure to obtain a colorless, viscous, colloidal polysilazane precursor; dissolve the polysilazane precursor in tetrahydrofuran or toluene, according to the Si / Al molar ratio Add aluminum isopropoxide at 0.5:1 and stir continuously for 48 hours at 90°C, filter and distill under reduced pressure to obtain a light yellow viscous liquid, tha...

Embodiment 3

[0038] First, repeat the vacuum-pumping-nitrogen-filling operation of the reactor for 3 to 5 times; then fill the entire reaction system with nitrogen at a rate of 1-10mL / s, open the nitrogen purge valve of the reactor, and make the nitrogen automatically overflow the reactor , to prevent air from entering; the tetrahydrofuran after dewatering was added to the above reactor cooled with an ice-water bath, followed by a mixture of methyldichlorosilane and methylvinyldichlorosilane, and then slowly at a flow rate of 30mL / min Access to NH 3 , stirred continuously for 12 hours, then filtered and distilled under reduced pressure to obtain a colorless, viscous, colloidal polysilazane precursor; dissolve the polysilazane precursor in tetrahydrofuran or toluene, according to the Si / Al molar ratio Add aluminum isopropoxide in 5:1 and keep stirring at 100°C for 24h, filter and distill under reduced pressure to obtain a light yellow viscous liquid, that is, polyaluminosilazane polymer. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com