Preparing method and application of catalyst for preparation of high-spherical low-particle-size polyolefin particles

A technology of high sphericity and polyolefin, which is applied in the field of olefin polymerization, can solve the problems of damage to the integrity of polymer chains, unfavorable processing, and increased processing costs, and achieve the effect of reduced particle size, reduced bulk density, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

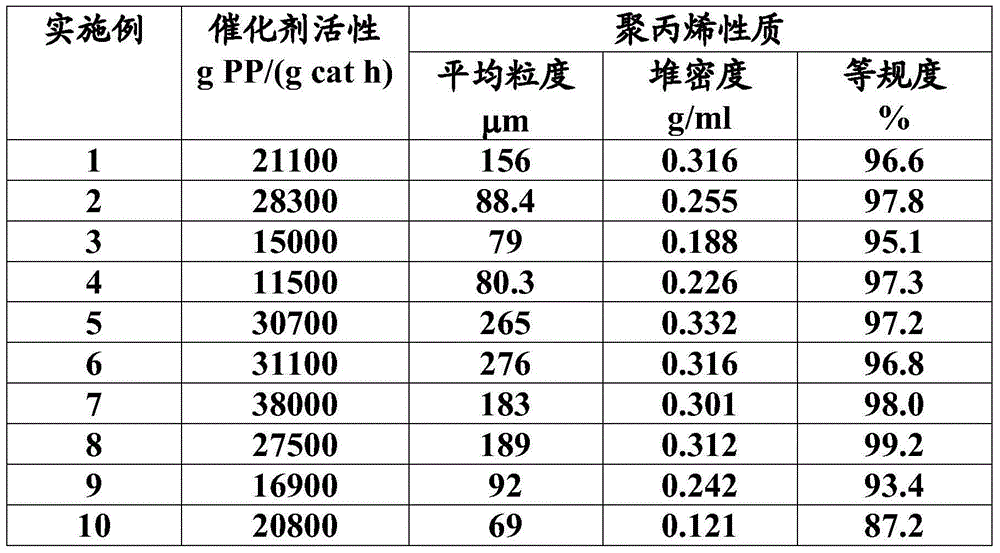

Examples

preparation example Construction

[0045] As mentioned above, the present invention discloses a method for preparing a catalyst for preparing polyolefin particles with high sphericity and low particle size, which includes the following steps:

[0046] (a) Mixing magnesium halide, alcohol compound, adjuvant, part of internal electron donor and solvent to prepare mixture I;

[0047] (b) Add the above-mentioned mixture I to the reactor, preheat it to -30°C-30°C, and add titanium compound dropwise; or,

[0048] Add the titanium compound to the reactor, preheat it to -30°C-30°C, and add the above mixture I dropwise;

[0049] (c) After the dripping is completed, the reaction system is heated to 90°C to 130°C in 30 minutes to 3 hours, and the remaining internal electron donor is added to continue the reaction;

[0050] (d) Filter out the liquid in the reaction system, add the remaining titanium compound, and continue the reaction;

[0051] (e) After the reaction is completed, post-treatment to obtain the catalyst.

[0052] Accord...

Embodiment 1

[0063] In the reactor fully replaced by high-purity nitrogen, add 4.94g of anhydrous magnesium chloride, 18.9g of isooctyl alcohol, 30ml of decane, increase the temperature to 130℃ with stirring and maintain for 2 hours, then add 2.65g of tetrabutyl titanate The ester and 2.05 g of diisobutyl phthalate were reacted at 130°C for another 1 hour, and finally cooled to room temperature to form a uniform transparent solution, which was Mixture I.

[0064] Add 200ml of titanium tetrachloride to the reaction kettle, stir and preheat to 0°C, and add mixture I to the titanium tetrachloride dropwise for about 2 hours. After the dropwise addition was completed, the temperature began to increase, and the temperature was increased to 110°C within 2 hours. 1.23 g of diisobutyl phthalate, an internal electron donor, was added. After reacting at this temperature for 2 hours, the reaction liquid was removed, and 200 ml of titanium tetrachloride was added again, and the reaction was carried out f...

Embodiment 2

[0067] In the reactor fully replaced by high-purity nitrogen, add 4.94g of anhydrous magnesium chloride, 18.9g of isooctyl alcohol, 30ml of decane, increase the temperature to 130℃ with stirring and maintain for 2 hours, then add 2.65g of tetrabutyl titanate The ester and 2.05 g of diisobutyl phthalate were reacted at 130°C for another 1 hour, and finally cooled to room temperature to form a uniform transparent solution, which was Mixture I.

[0068] The mixture I was added to the reaction kettle, stirred and preheated to 0°C, and 100 mL of titanium tetrachloride was dropped into the reaction kettle for about 1 hour. After the dropwise addition was completed, the temperature began to rise, and the temperature rose to 110°C within 2 hours. 1.23 g of diisobutyl phthalate, an internal electron donor, was added. After reacting at this temperature for 2 hours, the reaction liquid was removed, and 200 ml of titanium tetrachloride was added again, and the reaction was carried out for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com