Process device and method for avoiding combustible liquid storage tank gaseous-phase burning explosion and held pressure damage

A technology for process equipment and storage tank gas, which is applied in the field of process equipment to avoid gas-phase explosion and pressure-suppressed damage of flammable liquid storage tanks. Achieve the effects of preventing gas phase explosion, reducing usage, and preventing explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

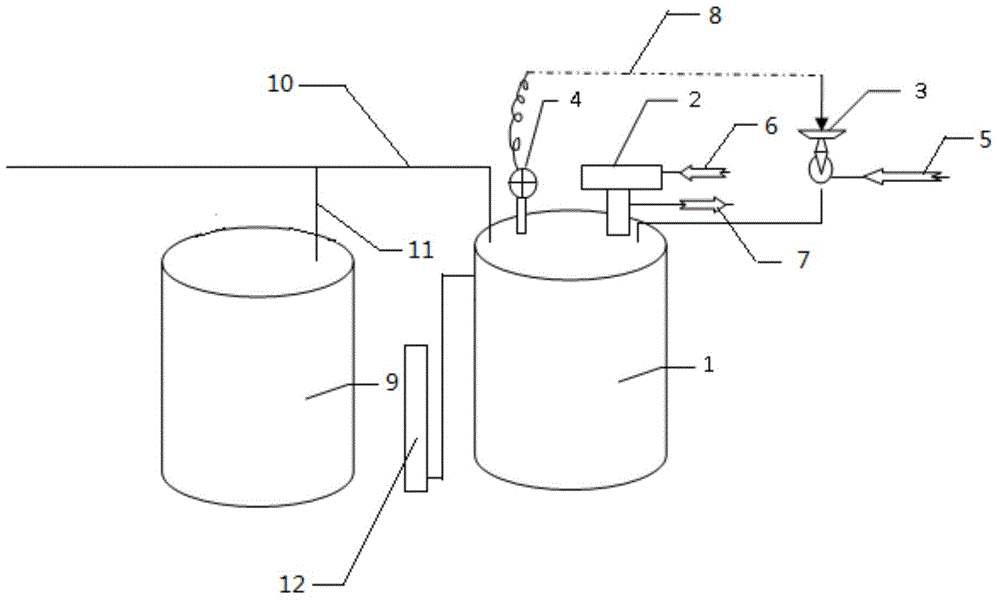

[0019] A process device and method for avoiding gas-phase explosion and pressure-suppressed damage of a flammable liquid storage tank, which is used for oil product storage tanks, and the oil products include gasoline, kerosene, diesel oil, dirty oil, naphtha, solvent oil, and crude oil etc., the device includes two storage tanks (9), buffer tank (1), breathing valve (2), oxygen content detector (4), supplementary nitrogen pipeline (5), regulating valve (3), two storage tanks The gas phase space of the tank (9) is connected to the main discharge pipeline (10) through the tail gas discharge pipeline, the outlet of the total discharge pipeline (10) is connected to the top of the buffer tank (1), and one end of the breathing valve (2) is connected to the bottom of the buffer tank (1). The gas phase space is connected, and the breathing valve (2) is provided with an air inlet (6) and an exhaust gas outlet (7). It is characterized in that the oxygen content detector (4) is arranged ...

Embodiment 2

[0023] According to the conditions described in Example 1, only the device is applied to the alkane storage tank, and the alkane includes pentane, hexane, cyclohexane, pentane oil and the like. When the gaseous oxygen content in the buffer tank is higher than 9.6%, the valve is automatically opened to feed nitrogen until the gaseous oxygen volume content in the buffer tank is lower than 9.6%; when the gaseous oxygen volume content is lower than 9.6%, the valve is automatically closed to stop feeding nitrogen. Through the above control loop, it is ensured that the oxygen volume content in the gas phase of the storage tank is lower than 9.6%. In the case of saving nitrogen, the gas phase of the alkane storage tank is prevented from detonating.

[0024] By adopting the device of the invention, compared with completely using nitrogen to protect storage tanks, at least 72.9% of nitrogen can be saved, and the safety effect achieved is completely consistent. At the same time, it prev...

Embodiment 3

[0026] According to the conditions described in Example 1, only the device is applied to an organic acid storage tank, and the organic acid includes formic acid, acetic acid, propionic acid, butyric acid, isobutyric acid, isooctanoic acid and the like. When the gaseous oxygen content in the buffer tank is higher than 5.1%, the valve is automatically opened to feed nitrogen until the gaseous oxygen volume content in the buffer tank is lower than 5.1%; when the gaseous oxygen volume content is lower than 5.1%, the valve is automatically closed to stop feeding nitrogen. Through the above control loop, it is ensured that the oxygen volume content in the gas phase of the storage tank is lower than 5.1%. In the case of saving nitrogen, the organic acid storage tank is prevented from detonating in the gas phase.

[0027] By adopting the device of the invention, compared with completely using nitrogen to protect storage tanks, at least 62.2% of nitrogen can be saved, and the safety e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com