Biomass burning heating jetting furnace with fire grate

A biomass and grate technology, which is applied in the field of biomass burning heating injection furnace, can solve the problems of complex structure, high manufacturing cost, and inconvenient movement of the furnace, and achieve the effects of unique design, energy saving, and reduction of smoke and dust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

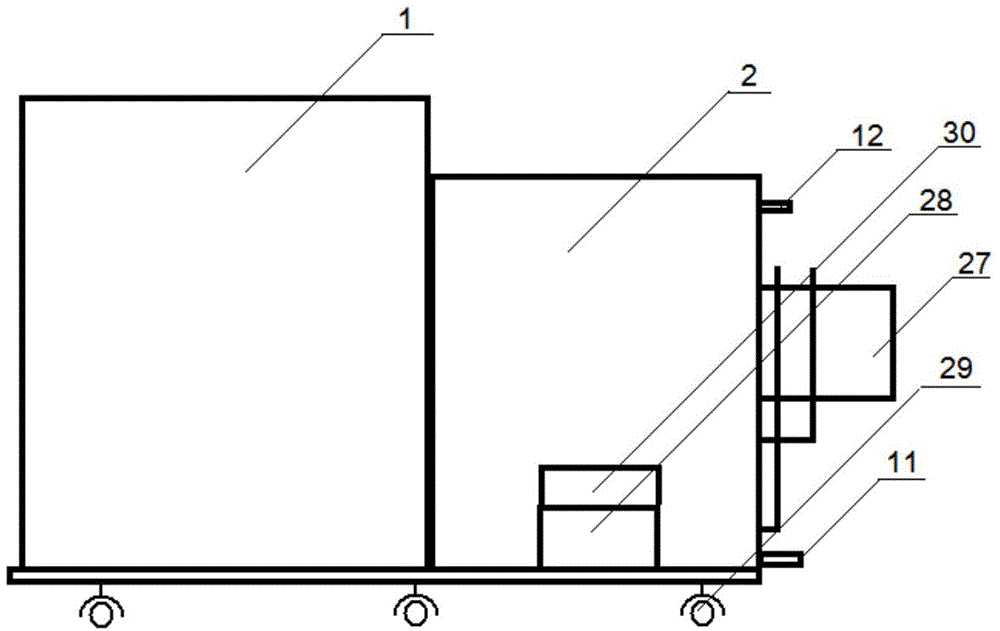

[0026]Embodiment 1: A kind of biomass combustion heating injection furnace with grate, the biomass burning heating injection furnace with grate is made up of equipment warehouse 1, furnace 2 and nozzle 27, and equipment warehouse 1 is equipped with for fueling the furnace The feed hopper 4 is connected to the furnace 2 through the pusher rod 5, the pusher rod 5 is provided with a screw push piece 6, the pusher rod 5 is connected with a power motor, and the equipment warehouse 1 is equipped with a furnace The bottom fan 21 and the furnace bottom fan 21 enter the furnace 2 from the furnace bottom air inlet 15 through the pipeline; the equipment compartment 1 is equipped with a main fan 13 and a gas distribution bin 14, and the main fan 13 supplies gas to the gas distribution bin 14 , the gas distribution bin 14 is connected to the lower air inlet 16 of the furnace and the upper air inlet 17 of the furnace through a pipeline; the gas distribution bin 14 in the equipment warehouse ...

Embodiment 2

[0027] Embodiment 2: A kind of biomass combustion heating injection furnace with grate, the biomass burning heating injection furnace with grate is composed of equipment warehouse 1, furnace 2 and nozzle 27, and equipment warehouse 1 is provided with fueling furnace The feed hopper 4 is connected to the furnace 2 through the pusher rod 5, the pusher rod 5 is provided with a screw push piece 6, the pusher rod 5 is connected with a power motor, and the equipment warehouse 1 is equipped with a furnace The bottom fan 21 and the furnace bottom fan 21 enter the furnace 2 from the furnace bottom air inlet 15 through the pipeline; the equipment compartment 1 is equipped with a main fan 13 and a gas distribution bin 14, and the main fan 13 supplies gas to the gas distribution bin 14 , the gas distribution bin 14 is connected to the lower air inlet 16 of the furnace and the upper air inlet 17 of the furnace through a pipeline; the gas distribution bin 14 in the equipment warehouse 1 is f...

Embodiment 3

[0028] Embodiment 3: A kind of biomass combustion heating injection furnace with grate, the biomass burning heating injection furnace with grate is made up of equipment warehouse 1, furnace 2 and nozzle 27, and equipment warehouse 1 is equipped with for fueling the furnace The feed hopper 4 is connected to the furnace 2 through the pusher rod 5, the pusher rod 5 is provided with a screw push piece 6, the pusher rod 5 is connected with a power motor, and the equipment warehouse 1 is equipped with a furnace The bottom fan 21 and the furnace bottom fan 21 enter the furnace 2 from the furnace bottom air inlet 15 through the pipeline; the equipment compartment 1 is equipped with a main fan 13 and a gas distribution bin 14, and the main fan 13 supplies gas to the gas distribution bin 14 , the gas distribution bin 14 is connected to the lower air inlet 16 of the furnace and the upper air inlet 17 of the furnace through a pipeline; the gas distribution bin 14 in the equipment warehouse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com